Setting up a warehouse design that optimizes productivity levels can be quite a hassle. In fact, there are many different types of operations and business areas to pay attention to when managing a warehouse—many of which most warehouse managers are not even aware of. As a result, running a warehouse successfully becomes a real challenge.

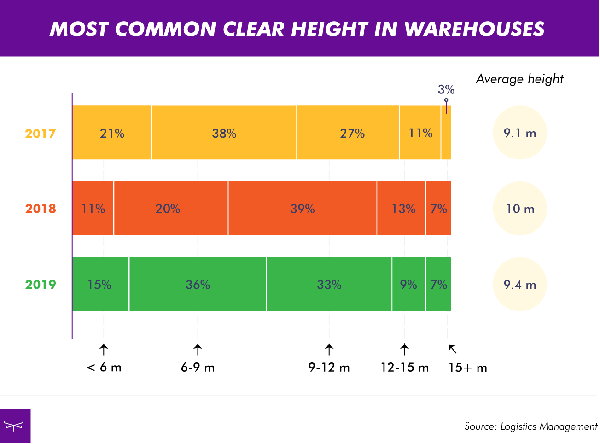

Running a successful warehouse begins with a proper layout, including the utilization of vertical space and regulating traffic flows. An inventive yet relatively easy way to minimise your fixed costs is by stacking and storing your inventory vertically, as it reduces the square footage of your warehouse.

In addition, it is important to properly manage your labor and processes to optimize productivity levels. This relates to the amount of workers you have, how you manage their schedules, the efficiency of workflows, and the type of training they receive to ensure that they have the right skills and can live up to the productivity expectations and requirements.

However, there is much more to running a successful warehouse, especially with the rising adoption of mobile robots and other automation. Let’s have a closer look at these.

Warehouse management systems

Traditionally, warehouses would be swamped with paperwork, ranging from paper picking lists to spreadsheets with inventory data. This method makes it difficult for warehouse managers to live up to the fast-paced, dynamic environment of today’s facilities. Therefore, to meet the ever-increasing customer demand on order accuracy and delivery speed, many businesses have started to embrace warehouse automation.

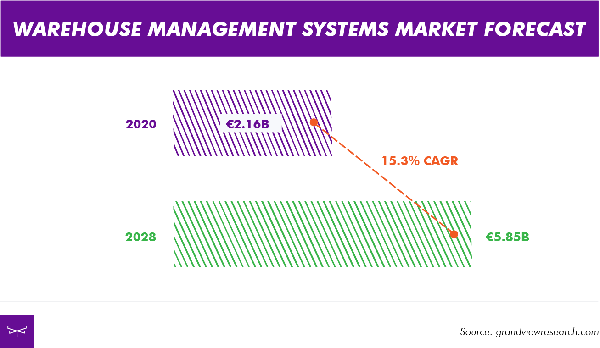

The warehouse management system (WMS) market is expected to see tremendous growth in the coming years. With a compound annual growth rate (CAGR) of 15.3% between 2021 and 2028, the WMS market value is expected to increase from $2.58 billion (U.S.) in 2020 to $6.98 billion in 2028, according to Grand View Research.

With a WMS, you can finally get rid of all that paper and instead focus on analyzing your operations and achieving optimal efficiency. However, there are a number of factors to keep in mind when considering a WMS:

- Choose a WMS that can be easily integrated into your existing interface.

- Assess the WMS’s core capabilities and activity requirements.

- Make sure you can measure your outputs in terms of capturing key performance indicators (KPIs), labelling, documentation, and management reports.

- Most importantly, choose a WMS that fulfills your operational requirements, regardless of its level of complexity. What matters the most is that its core functionality lives up to your needs.

Inventory management systems

Picking accuracy is directly linked to customer satisfaction and thus plays a huge role in the success of your warehouse. Today’s technology allows warehouse managers to optimize the accuracy of their inventory levels with ease. Commonly used methods include RFID technology and barcode scanners, but also the deployment of robotic solutions such as drones and inventory robots.

Again, merely implementing such a solution will not do the trick. It is equally important to align your labor and process management with this new technology, including training and keeping track of your overall performance and KPIs.

Inventory management goes hand in hand with warehouse visibility as both are closely related to data access. Warehouse managers must be able to accurately track and predict their inventory, supply, and demand.

In other words, it is crucial to have a system in place that helps track inventory accurately and efficiently. This includes all kinds of information regarding orders, including shipping dates, the number of returns, stock levels, etc.

The deployment of mobile robots

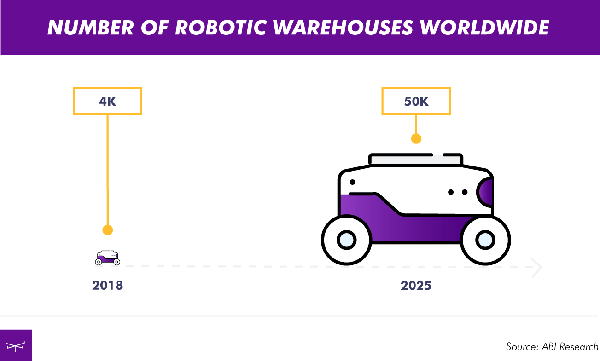

The ever-increasing need for visibility is one of the main drivers of innovation in the warehousing industry, and it is no surprise that the demand for autonomous mobile robots (AMRs) has also been increasing.

ABI Research estimates that there will be 50,000 robotic warehouses around the world by 2025, which is a huge difference from the mere 4,000 back in 2018.

However, as we have already seen, warehouse automation comes in many different forms — WMSes, inventory management systems, and mobile robots. Here are some other common automation solutions for warehouses:

- Integrating shipping management systems and automating the shipping process with the use of barcode scanners

- Deploying automatic pallet wrappers and box builders

- Replacing fixed conveyors with automated conveyor systems

- Implementing a universal fleet management system for existing robots

With the deployment of mobile robots, you will simultaneously be able to cross another couple of points off the list for running a successful warehouse. This includes safety and security. Not only will mobile robots help you reach your efficiency goals, but they will also create a safer environment for your workers and take over tasks that are likely to cause injuries.

Running a successful warehouse really starts with the warehousing basics — such as design, labor and process management, safety, and security. However, just focusing on these will not be enough if you want to take your business to the next level. With the wide variety of automation solutions available today, you can easily find one or more suitable ways to automate your operations and thereby optimize your overall productivity and efficiency.

About the author

Michelle Schlechtriem is the content manager at Meili Robots. She writes about marketing, technology, and sustainability.

Meili Robots provides a universal fleet management system called Meili FMS. The system is designed to allow robot operators to handle different types and brands of AMRs and AGVs in one system. The fleet management tool can be used for planning, assigning, and executing tasks through key features such as mapping, data logging, and data analytics, said the Copenhagen-based company.

Article topics

Email Sign Up