6 River Systems LLC today announced new features intended to enhance productivity and flexibility for warehouse operators. The new features are integrated with the company's software-as-a-service Fulfillment Execution System and its Chuck autonomous mobile robot, or AMR. 6 River Systems claimed that they position it “as the most configurable warehouse automation solution provider on the market.”

E-commerce sales will continue to grow by double digits in 2023, according to Insider Intelligence. Forrester predicts that business-to-business (B2B) e-commerce sales will account for 24% of total B2B sales by 2027. As a result of this growth, warehouse operators across market segments are seeking adaptable automation to support the workforce, increase margins, and drive throughput, said CBRE.

“Fulfillment can no longer be an afterthought as warehouses adapt to rising demand, labor costs, and faster SLAs [service-level agreements],” stated Rylan Hamilton, co-founder and CEO of 6 River Systems (6RS). “Our customers need smart, interconnected solutions that integrate with existing infrastructure.”

“Through both hardware and software, the improvements we made to our system empower warehouse operators to increase efficiency, stabilize labor, and support continuous growth,” he added. 6RS said the new functionality of its wall-to-wall fulfillment system will support customers’ changing needs.

“All of these features were based upon direct customer feedback and field studies on how we can help our customers improve operational efficiency,” Matt Fitzgerald, director of product management at 6 River Systems, told Robotics 24/7. “6RS is successful when our partners are happy, and our goal is to be a partner in that success.”

High Priority Chuck can decrease pick cycle times

6 River Systems said that it is committed to helping customers meet the key performance indicators (KPIs) that are most important to them, whether that is to deliver their customers’ next-day orders or to expedite specific jobs. A software update enables customers to quickly and easily use the feature, said 6RS.

“We got feedback that operations managers want the ability to identify Chucks with high-priority work on them,” said Fitzgerald. “The intent of the manager was to manually direct associates to specific Chucks.”

“We took this solution a step further by not just presenting operations managers that information, but extending the information to associates too,” he said. “That way, the system guides the user to the right place and eliminates a step—the need for operations managers to do this manually.”

When active, visual indicators such as flashing blue LEDs on Chuck and notifications in The Bridge command center signal prioritization. These visual cues can decrease pick cycle times and increase SLA attainment.

“We have not limited the visual indications to just the warehouse floor,” Fitzgerald said. “It was important for us to not segregate this data and instead, use it as a tool for everyone in the warehouse from pickers and managers alike.”

Universal Terminal to ease associate training

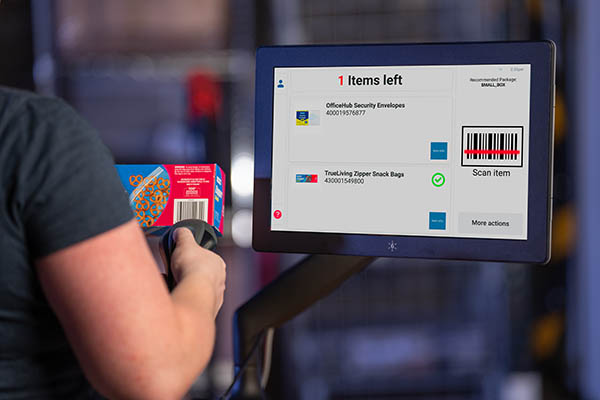

6 River Systems noted that its customers are seeking ways to increase the productivity and flexibility of their warehouse operations. The new Universal Terminal incorporates packout and sortation workflows into a single device.

It includes a touchscreen with 6RS’s common user interface (UI) to make training fast and easy, said the company. The modern interface also allows managers to move associates between workflows with minimal cross-training, increasing the flexibility of the existing workforce to meet shifting bottlenecks, it said.

The unit is universally mountable with adjustable height, making it ergonomically friendly while freeing critical benchtop space.

“Our customers have told us they want a common user experience across multiple workflows while having a minimal impact on their workspaces,” said Fitzgerald. “Universal Terminal can be reallocated to different stations when needed—sort, to pack, and back to sort.”

Work Areas provide one point of control across multiple areas

Customers building out their warehouses to support the increased demand for throughput need a system that allows for expansion and flexibility. 6 River Systems said its new Work Areas feature allows facilities to have multiple defined and independent areas of work running on one 6RS environment.

Work Areas can be multiple warehouse mezzanines on top of one another vertically or separate operating areas on the same level horizontally, allowing for further expansion and customization. 6RS said it can fully support multi-floor and multi-workspace fulfillment centers with a single, consolidated view of the entire facility.

“Today, Work Areas addresses the fundamental requirement to pick in multiple regions of the warehouse and manage that operation from one place—The Bridge,” said Fitzgerald. “We’re just getting started with this capability with plans to build upon the base functionality.”

Chuck Accessories improve efficiency, flexibility, and safety

Chuck is the most configurable AMR on the market because it accommodates many product and tote sizes, has configurable shelving heights to meet picking needs, and has numerous accessories to increase associate productivity, asserted 6 River Systems.

The company has developed a Workspace Tray to make tasks like splitting cases and counting small pieces easier and faster. It has also added a vertical and European ladder mount to Chuck so associates can reach SKUs located higher on the racks.

“The European Ladder Mount is a horizontal carry and storage of a ladder on Chuck which is mounted under one of the shelves,” explained Fitzgerald. “We named the horizontal ladder mount 'European Ladder Mount' because that is the primary market for the mount.”

“European safety requirements call for a three-point ladder, which is taller with a hand rail and is too long for a vertical carry,” he said. “In working with customers, we found they would rather preserve the usable workspace between the Chuck shelves if they can, and thus opt for vertical ladder carry whenever possible. 6RS does not provide the ladder but does provide the specs, so customers can make an informed purchase.”

These Chuck accessories can make associates more productive and efficient, increase flexibility, and improve associate satisfaction and safety, said 6RS.

“Through our relationship, 6RS has been an engaged partner, focused on developing the best hardware and software solution for Parker,” said Brandon Hetrick, a plant manager at Parker Hannifin. “We have completely overhauled our operation, and now we have associates that are more productive and far more safe.”

About 6 River Systems

Founded in 2015, 6 River Systems said it “provides the tools and insights needed to maximize operations as fulfillment speed becomes a competitive differentiator for warehouse operators and the merchants they serve.”

The Waltham, Mass.-based company operates in more than 100 facilities in the U.S., Canada, and Europe.

6RS's Chuck AMR fulfills millions of units each week for companies including GXO, Tagg Logistics, Crocs, DHL, and Office Depot. Shopify Inc. acquired the company in 2019.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up