X Development LLC, the innovation unit of Google Inc. parent Alphabet Inc., today announced that it has launched Intrinsic, a robotics software and artificial intelligence company. Intrinsic said it is developing software to give industrial robots the ability to sense, learn, and adapt to their environments so they can work in a wider range of applications.

“Intrinsic is working to unlock the creative and economic potential of industrial robotics for millions more businesses, entrepreneurs, and developers,” said Wendy Tan-White, CEO of Intrinsic. “We’re developing software tools designed to make industrial robots—which are used to make everything from solar panels to cars—easier to use, less costly, and more flexible, so that more people can use them to make new products, businesses and services.

Tan-White was previously a vice president at X, where she mentored projects including Mineral, which is developing tools to grow nutritious food more sustainably, and Tidal, which is exploring new ways to protect the oceans. She was also a serial entrepreneur and an investor in emerging technologies.

In 2000, Tan-White co-founded and was CEO of Moonfruit, which claimed to be the world's first software-as-a-service Web-site builder platform. She also helped launch Zopa.com, the first European peer-to-peer lending site, and helped launch Egg.com, the U.K.'s first Internet bank. In 2016, Tan-White was awarded an MBE for services to technology and business by Queen Elizabeth II.

Goals include sustainability, easier-to-use robots

“Currently, just 10 countries manufacture 70% of the world’s goods,” Tan-White wrote in a blog post. “This means most things are made far away from their end consumers, which drives global transport emissions, and many countries and businesses miss out on economic opportunities. Even countries with strong manufacturing sectors need help meeting demand: The U.S. manufacturing industry alone is expected to have 2.1 million unfilled jobs by 2030.”

Industry analysts have observed that much automation is still expensive and requires specialized programmers to use. Robotics and software vendors are working on making tasks such as welding, assembly, and machine tending easier for robots to do.

“Our team has been exploring how to give industrial robots the ability to sense, learn, and automatically make adjustments as they’re completing tasks, so they work in a wider range of settings and applications,” said Tan-White. “Working in collaboration with teams across Alphabet, and with our partners in real-world manufacturing settings, we’ve been testing software that uses techniques like automated perception, deep learning, reinforcement learning, motion planning, simulation, and force control.”

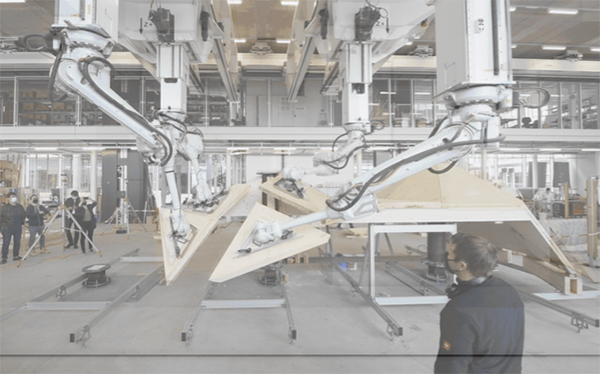

“In one instance, we trained a robot in two hours to complete a USB connection task that would take hundreds of hours to program,” she said. “In other tests, we orchestrated multiple robot arms to assemble an architectural installation and a simple piece of furniture.”

“None of this is realistic or affordable to automate today — and there are millions of other examples like this in businesses around the world,” claimed Tan-White. “This all hints at the potential for Intrinsic’s software to radically reduce the time, cost, and complexity required to use industrial robots — and therefore their long-term potential to help with a much wider range of problems and drive up the diversity of goods that can be produced affordably and sustainably.”

Intrinsic builds global team

X said that it its team includes people from companies acquired by Google in 2013 and who moved to X in 2015 after the formation of Alpabet. X describes itself as “Alphabet's moonshot factory,” working on developing and commercializing “breakthrough technologies designed to make the world a radically better place and create successful businesses along the way.”

The company described Intrinsic as its “other bet” in addition to Waymo autonomous cars, Verily Life Sciences for healthcare, and Wing delivery drones. Tan-White said Intrinsic has been working on its technologies for five and a half years, and it is looking for partners in the automotive, electronics, and healthcare industries that are already using robots.

Intrinsic's staff is based in Mountain View and Munich, Germany. It includes leading roboticists and AI experts such as Chief Technology Officer Torsten Kroeger, Engelberger Award winner Martin Haegele, robotics innovator Rainer Bischoff, and reinforcement learning expert Stefan Schaal.

The startup is hiring for several engineering positions.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up