Ambi Robotics has partnered with OSM Worldwide to deploy its flagship AmbiSort A-Series system to OSM’s warehouse locations in Atlanta, Chicago, and Las Vegas. OSM will be paying for the robots through minimum four-year robotics-as-a-service agreement.

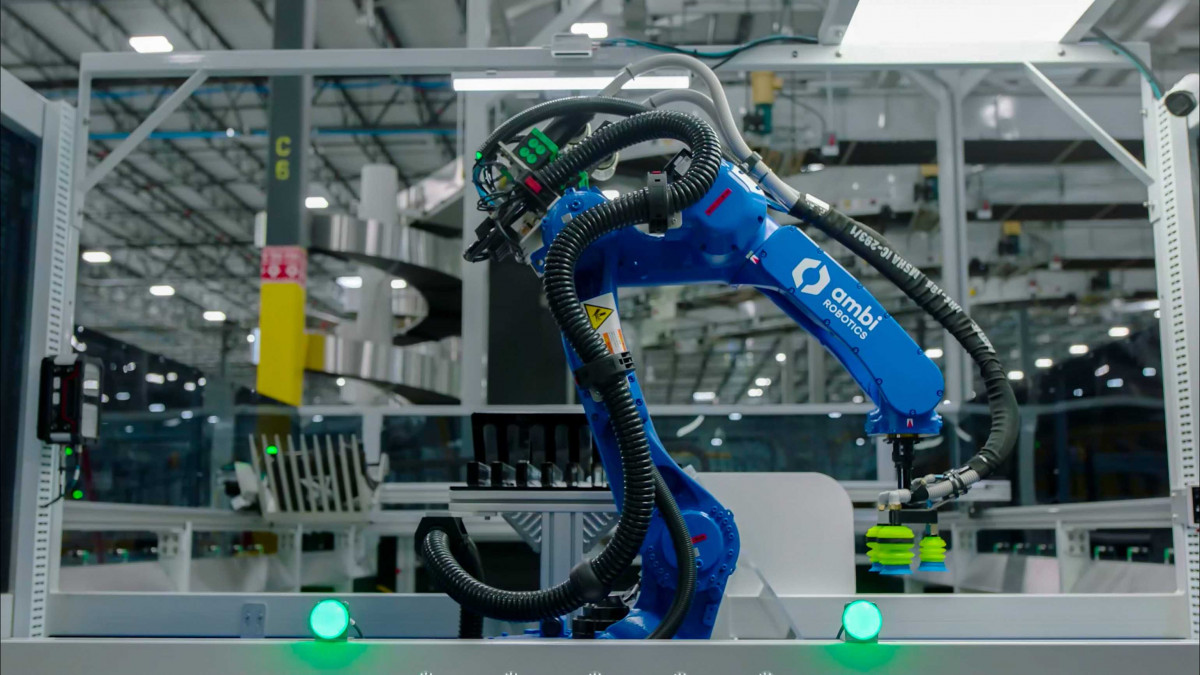

The AmbiSort A-Series is a configurable, AI-powered robotic sorting system that adapts to pick and sort mixed parcels like polybags, flats and boxes into last-mile mailsacks.

The systems are modular and configurable to accept parcels via rolling bin or the new conveyor-fed automated induction system.

The new AmbiSort A-Series conveyor-fed system improves the efficiency of existing parcel sorting applications by autonomously sorting parcels in a modular footprint that can be overseen by one operator for every three to four robotic systems, the Berkeley Calif.-based company said.

Simulation used for parcel sortation

Ambi Robotics’ systems are powered by AmbiOS, the company’s proprietary operating system that leverages advanced simulation-to-reality (Sim2Real) artificial intelligence (AI).

This technology enables Ambi Robotics systems to be hardware-agnostic and can be configured to meet the unique needs of each customer. AmbiSort systems are full-stack solutions combining both hardware and software.

AmbiSort systems from Ambi Robotics are first designed and trained in simulation, which speeds up training 10,000x faster than teaching algorithms in the physical world, it claimed.

Ambi said its AmbiSort A-Series system helps global shippers like OSM Worldwide accelerate parcel sortation to last-mile delivery providers while enabling ecommerce customers to benefit from cost-savings, order accuracy, and predictable performance.

“With increasing customer demand, our workforce at OSM Worldwide has grown over 126 percent in one year, and it’s critical that we equip our associates with the tools they need to operate efficiently and safely,” said Eric Hermonson, senior director of Human Resources at OSM Worldwide.

“While the technology speaks for itself, what makes Ambi Robotics such a world-class partner is the people - and their dedication in elevating the working conditions with assistive-automation,” Hermonson said.

Ambi Robotics takes into account human workers

Ambi Robotics noted that its solutions are rooted in human-centric design and enable the evolution of warehouse work by automating repetitive and potentially injurious manual sorting tasks while empowering associates to work more efficiently and safely.

“We are excited to partner with OSM Worldwide to deploy our AI-powered robotic parcel sorting systems and empower their warehouse associates to handle more,” says Jim Liefer, CEO of Ambi Robotics. “Our AmbiSort A-Series systems will help OSM Worldwide unlock new levels of productivity and profitability while improving the safety and job satisfaction of their valued employees.”

Ambi Robotics deployed an additional 60 robots to the company’s US customer base in under 60 days with less than 60 people, ahead of the 2022 peak holiday season. Now, Ambi Robotics has AI-powered robotic sorting systems spanning over 13 cities across the US and will add additional AmbiSort A-Series systems to three OSM Worldwide locations starting in April 2023.

Article topics

Email Sign Up