You hear a lot about big data analytics and machine learning to unlock insights in the world of the Industrial Internet of Things (IIoT). Now PTC and ANSYS are teaming up to transform traditional engineering simulation capabilities into a resource for building and optimizing smart connected products.

The pair announced plans to develop a platform solution that will allow ANSYS engineering simulation capabilities to be easily added to apps built on PTC’s ThingWorx IIoT platform. By connecting the two technology suites, the companies are setting forth on a journey that will eventually translate robust engineering simulation capabilities into tools for optimizing operations and maintenance.

Initially, ANSYS tools can be leveraged to create simulations that can be used as a source of data for instructing machine learning and predictive modeling—both mainstays of IIoT. Creating an on-going connection between real-world performance, simulation and machine learning is part of creating a more insightful feedback loop, which is also essential for helping engineers improve product design, officials said.

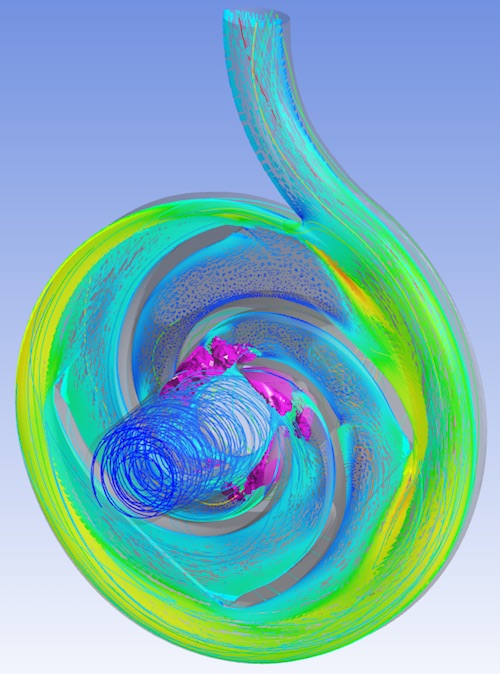

As part of an IoT platform, ANSYS simulation tools can deliver more insightful feedback to help engineers improve product design. Image Courtesy of ANSYS

As part of an IoT platform, ANSYS simulation tools can deliver more insightful feedback to help engineers improve product design. Image Courtesy of ANSYSANSYS simulation models can also play a role in developing the digital twin, providing advanced intelligence and insight into a product’s behavior for analyzing current operating conditions, rapidly identifying and diagnosing operational issues, and predicting future operating conditions—all capabilities that aren’t fully supported by PTC’s own simulation capabilities, according to Eric Bantegnie, vice president of ANSYS Systems Business Unit, and president of ESTEREL Technologies. The ANSYS multidisciplinary suite of simulation tools can fully digitally replicate the behavior of a component, which can then be integrated into the system model, providing additional richness and context for the digital twin, he explains.

“We can model fluid behavior, electrical behavior, software control behavior—we can simulate anything related to the functioning of a system,” explains Bantegnie, adding that the ThinkWorx platform can feed data into the ANSYS simulation to further refine that simulation.

PTC and ANSYS are teaming up to bring engineering simulation capabilities into IoT processes and workflows. Image Courtesy of ANSYS

PTC and ANSYS are teaming up to bring engineering simulation capabilities into IoT processes and workflows. Image Courtesy of ANSYSBantegnie identified three outputs where ANSYS simulation data could work in concert with ThingWorx.

The most immediate value of the partnership will be to enable engineers to leverage simulation capabilities to build and place virtual sensors in areas that aren’t physically possible in some products. “One of the biggest problems of industrial systems is that you can’t place sensors where you want because of physical properties like the temperature at the top of an aircraft engine, for example,” he explains. “There’s real data engineers care about that’s not reachable by sensors.” Using virtual sensors to collect data in hard to reach, but important areas, is critical to garnering the right insights, he continued. “You can’t predict engine core temperature if you don’t have access to the historical value of temperature,” Bantegnie explains. “We believe simulation technology can facilitate use of machine learning.”

The PTC/ANSYS partnership will also help expand the usage of simulation beyond engineering and design applications to applying it to operations, to determine the performance and potential problems with industrial equipment and field assets.

Longer term, Bantegnie expects the partners to collaborate on creating products and workflows that collect data by products once in use in the field, generate insights on their performance and quality using simulation algorithms, and feed that data back to engineering to direct subsequent design changes.

Watch this video to see where PTC, ANSYS, and partners are heading with IIoT analytics and workflows.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up