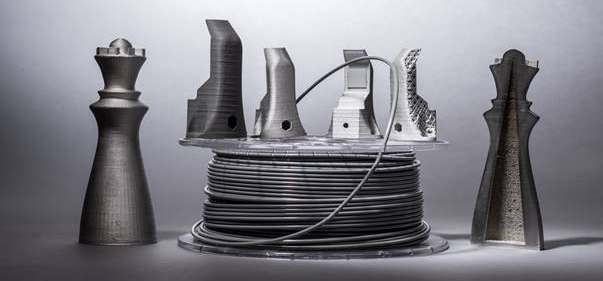

With Ultrafuse 316L, BASF 3D Printing Solutions launches a metal-polymer composite for fused filament fabrication (FFF). It enables the safe, simple, and cost-efficient production of fully metal parts for prototypes, metal tooling and functional metal parts in 3D printing, according to the company. After the subsequent industry-standard debinding and sintering, the final 3D printed part is 316L stainless steel.

FFF refers to a 3D printing process in which parts are built up layer by layer from moldable material. Ultrafuse 316L, a metal filament with polymer content, uses the same process; first, a suitable 3D printer builds a part layer-by-layer, with the polymer content of the filament acting as a binder. The main polymer content (primary binder) from the green part is removed in a catalytic debinding process. The result of this process is the brown part, which consists of pure metal particles and a residual binder (secondary binder).

The subsequent sintering process at temperatures right below the melting temperature of the metal removes the secondary binder from the brown part and causes the metal particles to coalesce. The material reaches its final properties post-sintering, for example with regard to hardness and strength.

The metal content in the high 90% range and the even distribution of the metal within the binder matrix reduces the risk of defects and increases the success rate. Due to immobilization of metal particles in the binder matrix into a filament reduces the potential hazards of handling fine metal powders compared to selective laser melting (SLM), direct metal laser sintering (DMLS), direct metal deposition (DMD) and binder jetting.

The new metal composite filament is flexible and strong: Ultrafuse 316L can be used with Bowden and direct drive extruders and can be guided through complex filament transport systems, according to the company.

“Ultrafuse 316L can, under certain conditions, be processed on any conventional, open-material FFF printer,” explains François Minec, managing director, BASF 3D Printing Solutions. “Our goal was to develop a high-quality metal filament that makes the additive manufacturing of metal parts considerably easier, cheaper, faster, and accessible to everyone.”

Sources: Press materials received from the company and additional information gleaned from the company’s website.

About the Author

Press releases may be sent to them via [email protected]. Follow Robotics 24/7 on Facebook

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up