In advance of the MODEX 2022 supply chain trade show, two companies addressed the challenge of automated bagging. Berkshire Grey Inc. and OSARO Inc. last week both announced new products that they plan to show in Atlanta.

“Warehouse and logistics operations globally are wrestling with an acceleration of consumer demand and a shortage of labor,” stated Derik Pridmore, CEO of OSARO. “By automating common manual processes such as movement, storage and retrieval, and picking and placing, fulfillment centers and e-commerce operations can become more efficient and cost effective—and improve employee safety.”

“Berkshire Grey’s Robotic Pick and Pack with Identification system for autobagging is the newest addition to our innovative portfolio of e-commerce solutions,” said Kishore Boyalakuntla, vice president of roduct at Berkshire Grey. “This system helps retailers increase their fulfillment throughput capacity while using sustainable autobagging approaches.”

Berkshire Grey RPPi uses AI for 'touchless' bagging

Berkshire Grey said it combines artificial intelligence and robotics to automate fulfillment, supply chain, and logistics operations. The Bedford, Mass.-based company claimed that its its systems can transform picking, packing, moving, and storage operations to deliver competitive advantage for enterprises serving today’s connected consumers. Berkshire Grey added that its customers include Global 100 retailers, same-day grocery, and logistics service providers.

The new Berkshire Grey Robotic Pick and Pack with Identification (BG RPPi) system uses machine learning to automate the picking of individual items and intelligently pack them directly into polybag, polyfilm, and sustainable packaging machines. It identifies orders in real time using advanced auto-identification and item-specific robotic manipulation technology, said the company.

BG RPPi also passes data to autobagging equipment to create labels and package the items for shipping. The system is compatible with leading autobagging brands, including Pregis and CMC, with additional integration partners in development.

Retailers and e-commerce providers can use BG RPPi for “touchless” autobagging, Berkshire Grey said. They can increase throughput capacity without needing to add labor, it said. In addition, the system allows for 24/7 autonomous operations, better use of sustainable packaging, and higher returns on investment (ROI) from existing equipment, according to Berkshire Grey.

BG RPPi can handle three times the number of SKUs than other robotic systems to automate the maximum volume of orders, the company claimed.

“With BG RPPi for e-commerce autobagging, we can now help retailers enable a touchless pick-to-ship fulfillment operation that is fully autonomous, thereby reducing labor dependency and increasing overall productivity,” Boyalakuntla said.

OSARO upgrades picking systems

OSARO designs and deploys materials handling automation with software-defined robotics, machine learning for object recognition, and control software. The San Francisco-based company said it has optimized its piece-picking systems for e-commerce, where key challenges include high SKU inventories, complex packaging, and fragile items requiring delicate handling.

In addition, OSARO said its piece-picking robot integrates easily with existing logistics facilities to fulfill orders quickly and efficently. It is available as a “drop-in” upgrade to existing or new warehouse and direct-to-consumer operations, said the company.

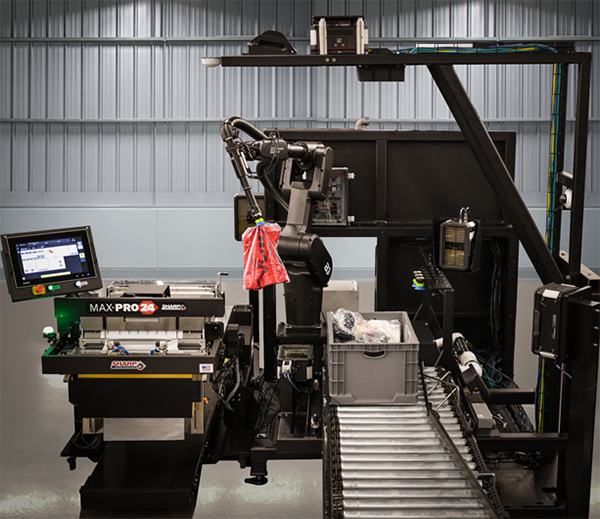

The OSARO Automated Bagging Solution is “the first comprehensive robotics solution for automated bagging,” the company claimed.

Unlike conventional automation products, OSARO said its system offers object recognition and manipulation to augment bagging productivity. Operating with minimal human oversight 24/7, it can streamline the packing and shipping of a wide range of items at a rate of 350 parts per hour, said OSARO.

OSARO integrates with packaging machinery

OSARO added that its software works with robots and automated bagging machines from leading vendors such as PAC Machinery and Pregis.

“PAC Machinery provides innovative packaging solutions that give our customers a competitive edge,” said Greg Berguig, vice president of sales and marketing at PAC Machinery. “PAC Machinery poly-bagging systems, coupled with OSARO’s smart robots, are the fastest path to the next level of automation.”

“Pregis’ automated packaging systems, powered by Maxwell Technology, integrate into end-of-line workcells,” said David Schuda, vice president of technology at Pregis. “Our solutions, with OSARO’s technology and robotics, extend automation capabilities throughout the fulfillment process, improving pack times, order accuracy, and product protection while reducing material waste.”

Berkshire Grey, OSARO to be at MODEX

Berkshire Grey's automation portfolio includes package sortation and identification systems, robotic shuttle put walls and product sortation, and mobile robotic sortation and fulfillment. The company plans to show BG RPPi for e-commerce autobagging and other systems at Booth B4207 at MODEX 2022.

OSARO will demonstrate its technology at Booth C3794 at the show from March 28 to 31 in the Georgia World Congress Center.

Article topics

Email Sign Up