DHL has opened a robot picking system at its facility in Staufenberg, Germany to help satisfy the demands of its customers. The company enlisted the help of systems integrator Element Logic to install an AutoStore automated storage retrieval system, or ASRS, that now covers 6,000 square meters at the facility.

The system is made up of 160 robots, which are being used to sort orders for clothing store customers across Europe, including Peek & Cloppenburg Düsseldorf, one of its largest.

The Bonn, Germany-based company said the facility warehouses more than 3.5 million fashion items for customers in places such as Austria, Poland, and the Netherlands, and is used to process new merchandise as well as returns.

AutoStore system allows for more efficient tracking

“The AutoStore system there allows merchandise inventory to be fully monitored and controlled, ensuring high efficiency in storage and retrieval,” the company said in a statement. “This enables customer orders to be processed and shipped with greater speed and reliability.”

“The interplay of the flexible and modularly expandible robotics solution with the local employees reduces throughput times for individual customer orders, from order placement to dispatch from the warehouse, simplifies operational processes for employees, and increases operating efficiency,” the company added.

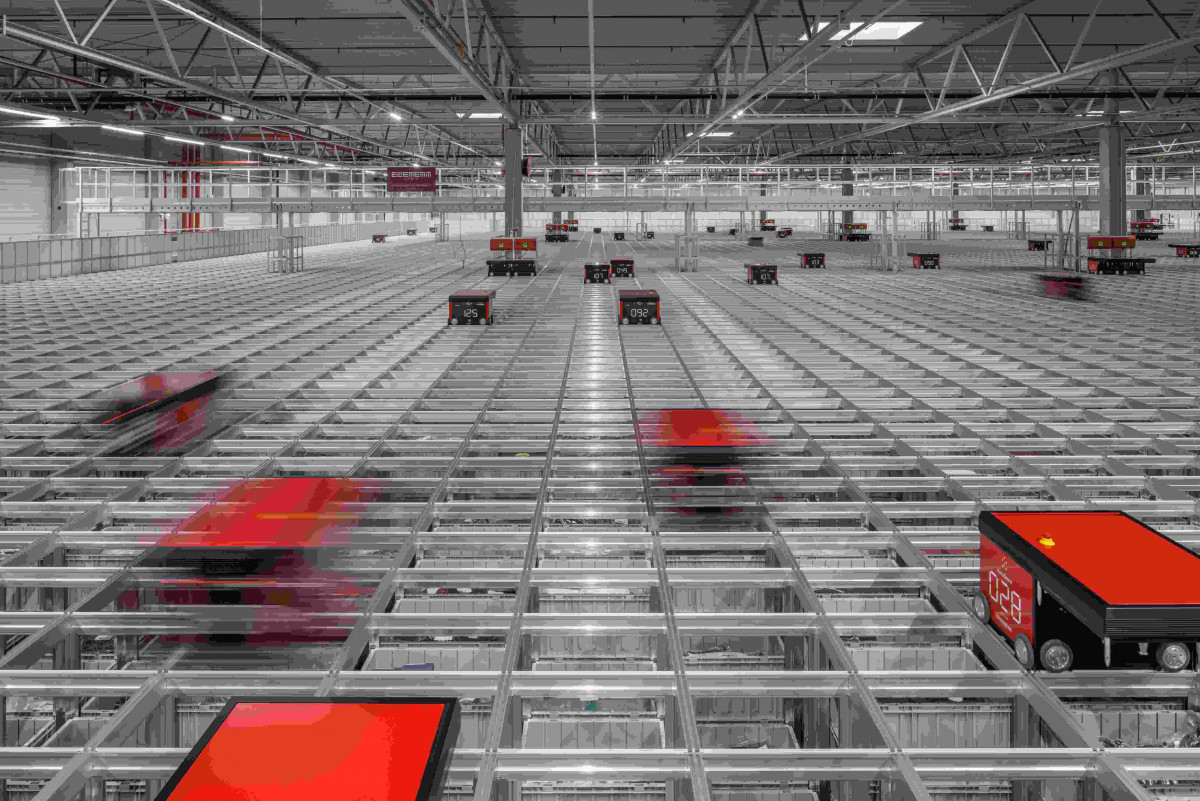

It all starts with a 16-level high aluminum framework where inventory is stacked and stored in 196,000 plastic bins, according to the company.

The framework acts as a grid for the 160 robots to navigate around while they pick items. From that area, goods are processed and prepared for shipping and humans are brought back into the loop.

“We are thrilled to facilitate the omnichannel growth of a long-time customer like Peek & Cloppenburg Düsseldorf with the help of this automated solution,” Rainer Haag, CEO of DHL Supply Chain Germany & Alps, said in a statement. “It enhances our partnership and is an investment in the future success of both our companies.

“Staufenberg is an ideal location for this operation in terms of transport connections and offers us a direct link to our sister divisions DHL Paket and DHL Express,” Haag added. “On average, we can deliver 85% of parcels by the next day to recipients in Germany.”

_.jpg)

DHL and AutoStore are helping build Peek & Cloppenburg brand

Mode Logistik GmbH & Co. KG, a subsidiary of Peek & Cloppenburg, said the AutoStore system is helping the company to realize its vision of being “the leading multi-brand omnichannel retailer for fashion in Europe by 2026.”

“This type of solution enables us to better meet the needs and expectations of our customers,” stated Marco Rebohm, managing director of Mode Logistik GmbH & Co. KG,. “And the higher speed and reliability of the system makes it possible for us to easily handle our steadily growing order volumes.”

“We're happy to have DHL Supply Chain as our partner,” Rebohm added. “It's a company with whom we can develop and implement new solutions hand-in-hand.”

DHL is not just investing in robotics in its home country. In November, the company announced that it plans to install 1,000 robots at its Australian warehouses to meet rising demands and to be more flexible.

Article topics

Email Sign Up