Conventional metal 3D-printed repair of damaged mechanical parts in machines requires bulky equipment and wastes metal powder, according to researchers at the Tokyo University of Science. Although laser-directed energy deposition overcame this challenge, the optimum forming conditions had to be determined by trial and error.

Parts in industrial machinery and structures that develop thinning or cracks need to be replaced with new ones. In recent years, attempts to repair them have been considered to improve industrial sustainability. As a result, repair technology for machines has been a hot topic of research and development, noted the university.

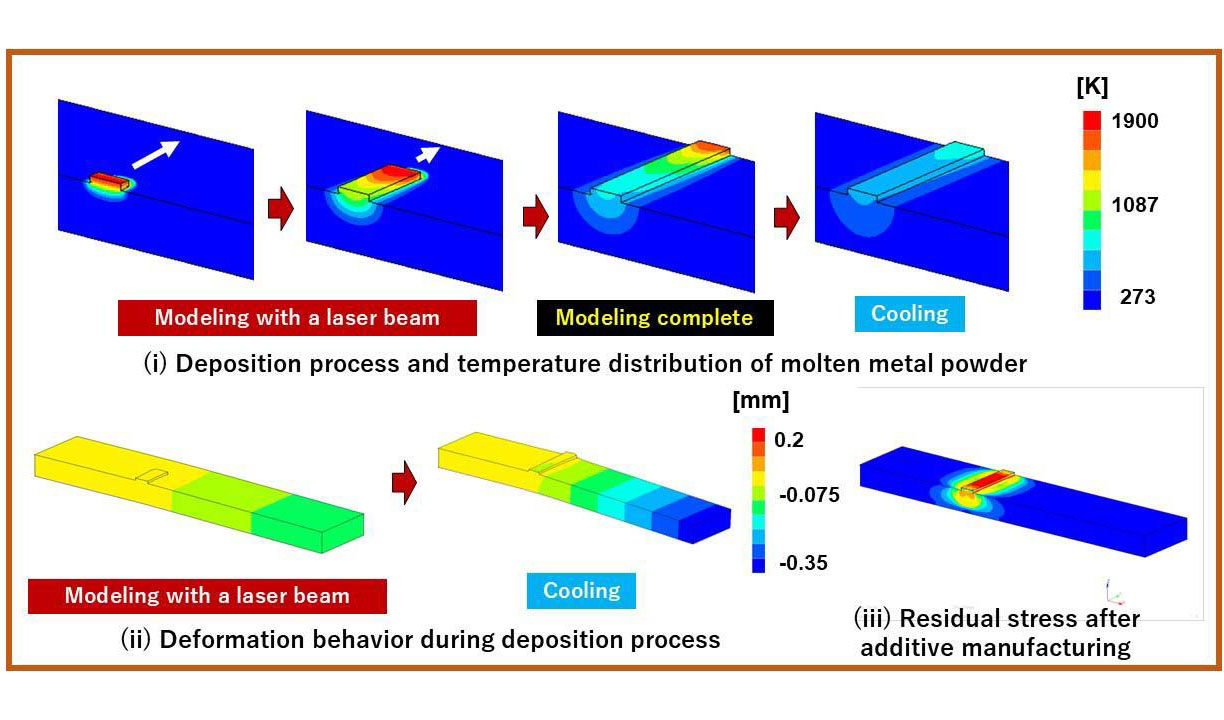

Researchers at Tokyo University of Science (TUS) said they have developed a numerical method that automatically generates metal powder deposition elements. It can predict forming process conditions, temperature distribution, deformation state, and residual stress distribution in advance.

Digital twins offer less bulky 3D printing

Conventional metal 3D-printed fabrication uses the surface of a mechanically laid powder bed that is irradiated with a laser or electron beam to melt the metal particles and fuse them. However, this method requires bulky fabrication equipment, said the scientists.

In addition, a large amount of metal powder is disposed after the fabrication process, they noted.

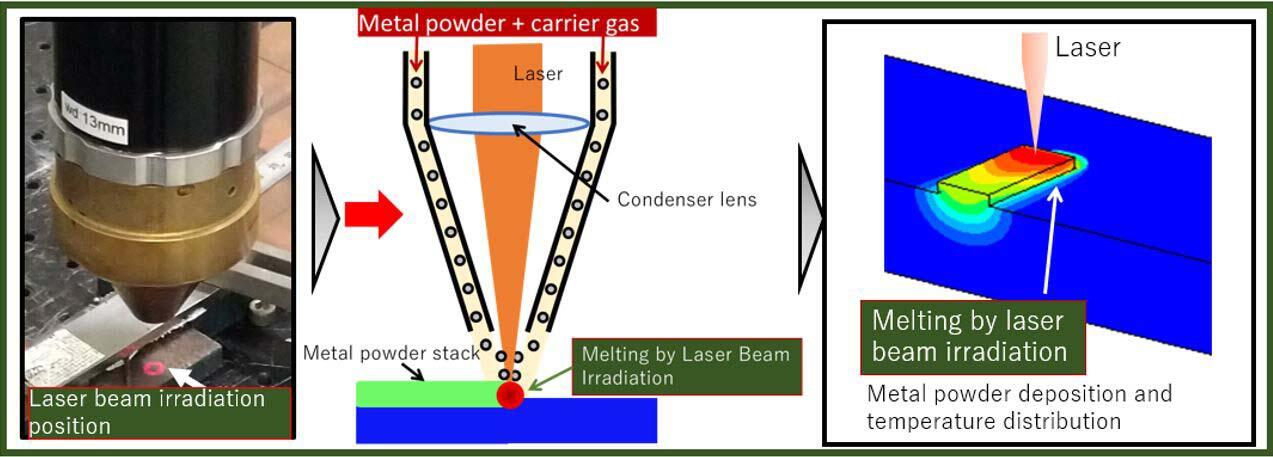

However, laser-directed energy deposition (LDED) is a promising technology that overcomes the challenges, said the Tokyo University of Science. In this technique, metal powders are deposited at the focus of a laser beam, then melted and stacked.

The advantages of LDED are not only related to the compactness of the equipment, but also the significant reduction of metal powder waste, said the team. Furthermore, it said, this technology enables in-situ metal powder fabrication in a 3D shape on the surface of a substrate, so it can be used to repair machines made of metal.

The research group included Prof. Masayuki Arai from the Department of Mechanical Engineering at TUS, Toshikazu Muramatsu, also from TUS, and Dr. Kiyohiro Ito from Department of Mechanical and Electrical Engineering at the Suwa University of Science in Japan.

They have collaborated with the Thermal Spray Technology Development Laboratory of TOCALO Co. to develop a repair technique using LDED.

“Using our technique, the surface shape of a metal structure can be completely restored onsite, and the disposal of the metal powder required for repair can be significantly reduced,” explained Prof. Arai, who has been actively involved in the research of damage mechanics and repair technology. “However, the optimum forming conditions required for the widespread application of this technology in industry had to be hitherto determined by a trial-and-error process.”

Tokyo University of Science devises mathematical LDED model

In a recent article published in Journal of Thermal Spray Technology, the researchers have devised a mathematical model of LDED that automatically generates a metal powder deposition region using a death-birth algorithm, eliminating the guesswork needed to optimize the production.

“The thermal radiation-thermal conduction model and the viscoplastic-thermoplastic constitutive model are applied to the stacked elements that constitute the deposited region, so that a wide range of state changes from melting to solidification of the deposited layer of metal powder can be faithfully simulated,” noted Arai. “By incorporating these models into a finite element analysis program, we have developed a new machining analysis system that has never been used before.”

The team numerically simulated the restoration process and was able to predict the forming process conditions. It verified the findings through experiments. The TUS researchers found that the residual stresses in the deposited layer were much lower than those obtained via conventional repair processes.

This novel 3D machining numerical analysis system is a digital twin of the existing core machining technology based on the fusion of metal in the area to be repaired, said TUS.

This numerical analysis method could be applied to various industrial applications, such as planning the repair of cavitation thinning on the surface of a blade used in power plant's circulating pump and devising a method for reducing residual deformation after repairing the thinning of the tip of a gas turbine's rotor blade.

The Tokyo University of Science team claimed that automation combined with prediction of process conditions could make 3D metal layered metal fabrication by LDED repair technology more effective. By managing resources more efficiently, the digital twins could also improve the production method's environmental sustainability, it said.

Article topics

Email Sign Up