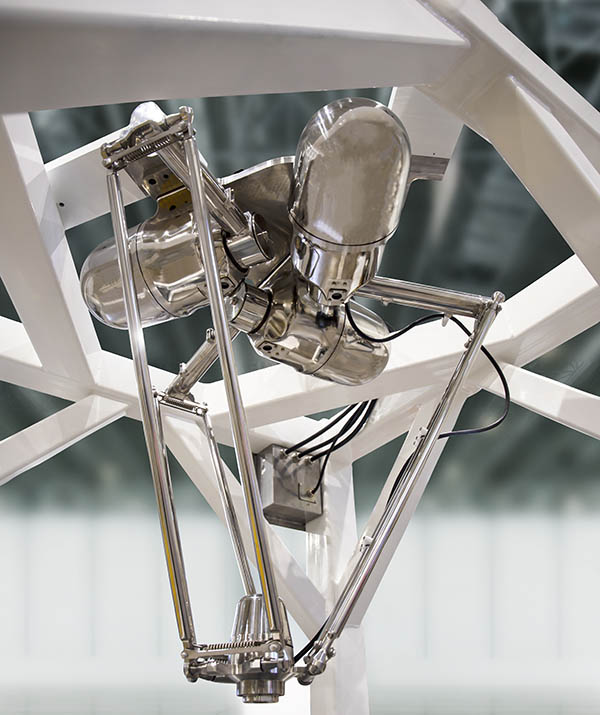

Robotics manufacturer FANUC America recently announced it will demonstrate a range of its robots at the Automate 2022 trade show in Detroit. That includes the company’s first stainless steel food grade delta robot for picking and packing primary food products, the DR-3ib/6 STAINLESS delta robot.

The new DR-3iB/6 STAINLESS delta robot, using a Soft Robotics gripper, will pick bakery, dairy, and meat products from the middle section of the demonstration’s work area and place them in specified zones.

Stainless-steel design for food packing environment

The DR-3iB/6 STAINLESS features a fully enclosed stainless-steel body that is resistant to the chemicals and high pressure/temperatures required in strict wash down environments, the company said.

With additional features such as NSF H1 food-grade lubricant, secondary oil catch basins (with viewing windows to monitor potential leaks), self-draining surfaces, and many other small details driven by USDA/FDA standards, the DR-3iB/6 STAINLESS is ideally suited for primary food handling applications, according to FANUC America.

“The new DR-3iB/6 STAINLESS robot combines FANUC’s industry-leading performance and reliability with a food-safe stainless steel construction,” said Jessica Juhasz, staff engineer at FANUC America. “We’re happy to offer a food processing robot that will help companies maximize production efficiencies without compromising food safety.”

The DR-3iB/6 STAINLESS has a 1,200 mm (47 in.) reach and a 400 mm height (15.78 in.) and a powerful four-axis design allowing it to handle 6 kg (13 lb.) payloads at high speeds.

The new robot operates with FANUC’s latest R-30iB Plus controller with integrated intelligent functions such as iRVision, force sensing, Robot Link, collision guard, and Zero Down Time.

CRX and CR Cobot Demonstrations at Automate

FANUC will also demonstrate a wide range of its CRX cobots at the show to address a variety of industrial applications.

The new CRX-5iA cobot, featuring a 5 kg (11 lb.) payload and 994 mm (39 in.) reach will make its first appearance in North America at Automate. The CRX-5iA will pick and assemble small gears using integrated force control.

First, the CRX-5iA with integrated force control will pick different height gears (short and tall) from a stack. Using the “touch skip” feature, the cobot will determine the height of each gear. Next, the CRX-5iA will assemble the selected gear using integrated force control’s “Phase search” function.

A CRX-10iA welding cobot will allow attendees to teach weld joints using hand guidance or a tablet interface with drag-and-drop icons.

The CRX welding cobot supports FANUC’s advanced features including iRVision, Torch Angle Control, Touch Sensing and Thru Arc Seam Tracking (TAST). The CRX will use Lincoln Electric’s Power Wave R450 robotic power source, and the new Lincoln Electric Smart Torch. Built for the industrial space, the CRX-10iA welding cobot is compatible with Lincoln Electric’s weld programs to help customers maximize productivity.

A new CRX-25iA robot, offering a 25kg (55 lb.) payload and 1,889mm (74 in.) reach will demonstrate case palletizing.

A CRX-20iA/L with FANUC QSSR (Quick & Simple Start-up of Robotization) will demonstrate the easy connection of a FANUC CRX cobot and a machine tool. QSSR simplifies the automation of machine tool load/unload applications using the CNC controller’s easy guidance functionality for quick connectivity, start-up and operation.

FANUC CR-35iB will assemble a bike

At the show, the CR-35iB collaborative robot will help an operator assemble a bicycle. The operator will program various assembly positions with the easy-to-use tablet TP featuring a “drag and drop” user interface.

The demonstration underscores the cobot’s ability to make the assembly process quicker while eliminating ergonomic stress, the company said.

The CR-35iB collaborative robot has a payload of 35kg (77 lb.).

M-1000iA will be used for battery assembly

The M-1000iA equipped with iRVision will highlight the EV battery assembly process.

The new M-1000iA robot is capable of handling very heavy products including automotive components, construction materials, and battery packs for electric vehicles, the company said.

The M-1000iA’s serial-link construction allows a wider range of motion in every direction. It can extend its arm upright or rotate it backwards, which is not possible for typical heavy-payload robots with a parallel-link mechanism, the company said.

With a 1000 kg (2,204 lb.) payload, a 3,253mm (128 in.) horizontal reach, and a 4,297mm (169 in) vertical reach, the M-1000iA is a good choice to help manufacturers increase output and maximize efficiency, the company said.

FANUC LR-10iA/10 Robot will be used for vision-guided piece picking

The FANUC LR-10iA/10 robot guided by four 3DV/400 vision sensors mounted over the workcell will pick various combinations of products from four separate totes to demonstrate order fulfillment.

When the order tote is completed, it will move to the opposite side of the cell, where an LR Mate 200iD robot will pick and place each item back onto the conveyor, sorting them by color to refill the pick totes.

FANUC’s new LR-10iA/10 robot is designed for machine tending and many picking applications found in the warehousing and logistics markets, the company said.

Weighing just 46 kg (101 lb.), the LR-10iA/10 robot mounts to the floor, upside down, or on an angle. It’s also very easy to mount the robot to an AGV or other mobile platform.

The LR-10iA/10 has a 10 kg payload and a large work envelope with a long reach of 1,101 mm. (43 in.) Its compact size accommodates tight floor spaces, and a slim arm fits easily into machine tools for part load/unload, the company said.

In addition, an enclosed structure makes it easy to integrate, and an IP67 rating allows it to operate in environments with dust, water, and oil mist.

More robotic demonstrations at Automate

Also at Automate in Detroit, the FANUC M-2000iA/1700L will handle a 2020 Chevrolet Corvette to demonstrate how assembled automotive bodies are commonly handled in OEM facilities.

The demonstration will also feature Dual Check Safety (DCS) Speed and Position Check software, which limits the robot’s envelope within a compact workspace.

The Paint Mate 200iA robot will use iRVision 3DV and line tracking to paint ACT test panels placed randomly on a conveyor. First, the integrated robot vision system will identify the part type and orientation. Next the robot’s HVLP spray gun will simulate painting the part. The demonstration will highlight the robot’s ability to quickly adapt to randomly-oriented or shifting parts.

The R-2000iD/210FH robot equipped with integrated FANUC Servo Gun Control and a hollow arm for spot welding dress out will perform simulated spot welding in and around a truck cab.

The FANUC’s SR-12iA SCARA robot will pack and unpack four-packs of two-liter pop bottles. The demonstration shows the SR-12iA’s ability to handle heavy products in a wide operating area at high speeds, the company said.

Factory automation demonstrations at Automate

The company will have a Linear Motor demo arranged in an X/Y table application.

FANUC said its new LiS-B series linear motors have set new standards for acceleration, precision and speed, delivering high gain and rigidity with excellent path accuracy.

Unlike conventional drives, these motors work without any force transmission mechanisms, making machine design and maintenance easier (no ball screws, no backlash), the company said. The linear design enables rigid long-stroke axes, increased thrust force and multi-head configurations by arranging multiple coil sliders on a single magnet track.

The company will also have a Panel I Industrial PC demo.

Article topics

Email Sign Up