Software is increasingly becoming a differentiator in automation. Formant today said it has partnered with Kinova Inc. to support Kinova's Gen 3 robot arm with its cloud platform.

“Kinova continues to be a leader in industrial and medical robotics,” stated Jeff Linnell, CEO of Formant. “As more and more companies adopt Kinova’s Gen 3 arm, we’re excited to partner and have the opportunity to make the experience of operating the arm as smooth as possible for our users. Together, we hope to continue to bring the benefits of robotic arms to hospitals, warehouses, research centers, and more.”

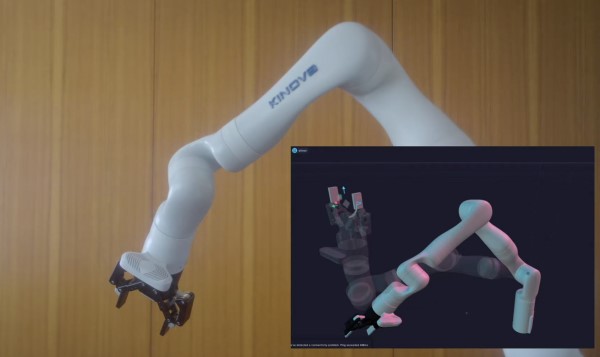

Formant said it has built a feature to “natively support seamless remote operation and create a smooth experience for users of the Gen 3 arm.” The San Francisco-based company said its browser-based application is able to ingest and record data generated by Kinova's arm. It also allows for easy teleoperation and remote configuration, Formant said.

“Formant and Kinova share the same vision and enthusiasm regarding the next age in robotics,” said François Boucher, vice president of strategic growth at Boisbriand, Quebec-based Kinova.

“Moving from individual automated cells in a manufacturing facility towards distributed networks of robots in hospitals, farms, and other atypical environments for robots requires solutions that are flexible and scalable,” he added. “Formant is definitely elevating the Gen3 robot in that regard, that’s the reason why we are so thrilled about this partnership.”

Formant said more information is available at its website. James Turnshek, chief architect at Formant, replied to the following questions from Robotics 24/7:

So can a user instruct a Kinova arm what to do, and other arms will be able to do the exact same motion using Formant's software, regardless of location?

Turnshek: Formant allows for fleet-wide device configuration management, which can include assets such as pre-defined plans.

So if a user were to define an action using software from Kinova or another application, they could deploy it to the fleet using Formant.

What are the challenges in ingesting the position data? Does it factor in speed?

Turnshek: In general, recording high-frequency data from robots to the cloud involves many challenges such as dealing with limited bandwidth, intermittent connectivity, ingestion processing scalability, and long-term storage with fast retrieval.

Standard streams ingested into Formant for a Kinova arm will include the 3D transform tree, the IMU [intertial measurement unit] data, torque, temperature, power consumption, as well as the state and velocity of each joint. These can be sampled at up to 20Hz or higher using raw data recordings.

In addition to adding this capability to Kinova's arm, how does it compare with other teleoperation software?

Turnshek: Formant now provides an out-of-the-box Kinova integration, but our teleoperation software is fundamentally robot-agnostic and can be extended with custom control applications.

It provides low-latency channels for common robot data types such as video streams, point clouds, 3D poses, numerics, and Booleans. All data is also recorded and uploaded to the cloud so that it can be reviewed later.

A programmed cobot arm will still stop if it comes into contact with a person or other obstacle, right?

Turnshek: Yes, Formant doesn’t override any of the specific behavior of the Kinova arm.

Formant just provides the higher-level control, like the desired end-effector pose or desired joint angles. The standard drivers are then responsible for moving the arm and maintaining safe behavior.

Is this going to be offered through a software-as-a-service arrangement or as an add-on to Kinova's offering?

Turnshek: The integration will be offered to Kinova customers who want to use Formant as their cloud robot management platform.

Can you give examples of some specific applications where this combined technology will be useful?

Turnshek: Any application that requires a robot to continuously perform a task on its own benefits from observability and configuration management, and any robot that needs remote assistance benefits from teleoperation.

Common applications where Formant is used with Kinova or other robot arms include mobile manipulation in a variety of industries such as healthcare and industrial inspections, pick and place, machine tending, light assembly, assistive devices, and research.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up