Automotive technology company FORVIA recently announced that it has installed 14 autonomous mobile robots, or AMRs, made by Mobile Industrial Robots at its Fauercia Clean Mobility plant in Písek, Czech Republic.

With 266 industrial sites, 39 R&D centers and 114,000 employees in 35 countries, FORVIA claims to be a leading global automotive supplier. The plant in Písek focuses on exhaust systems production for a wide range of customers, mainly Volvo, Daimler and PSA. The site in Písek has been in operation since 2006 and currently employs around 500 people.

The company said it focuses on three key areas: electrification and energy management, safe and automated driving, and digital and sustainable cockpit experiences.

How are they using the AMRs

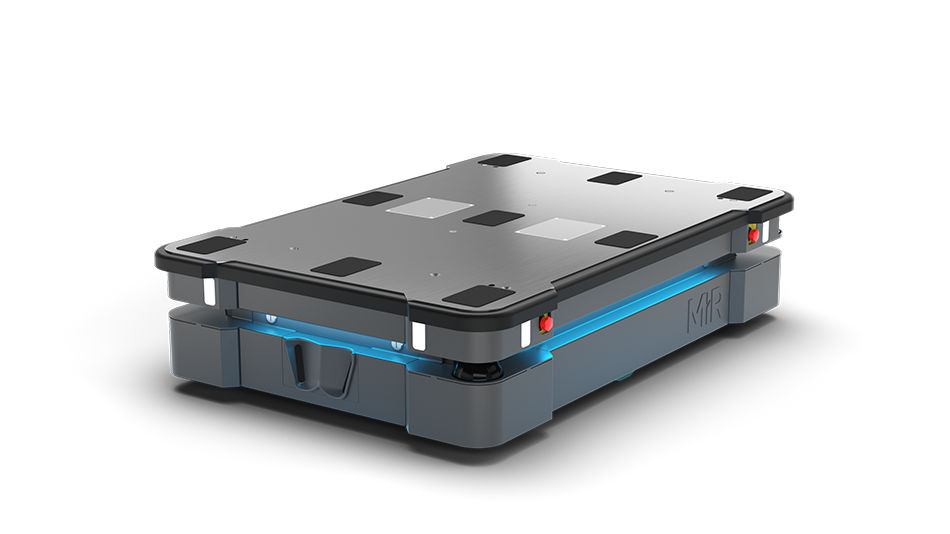

Seven of FORVIA’s heavy duty MiR robots, mainly MiR600s, work in finished goods, bringing empty pallets to the assembly lines and picking up full pallets to transport to the logistics area. MiR250 robots are also being used to move components from the warehouse to assembly lines. The robots in the plant work 24/7, covering all three operation shifts, the company said.

Martin Horáček, supply chain operations manager in Faurecia Clean Mobility Europe, said the AMRs help the company adapt to changing workflows and provide greater flexibility.

“Our shop floor environment is extremely live and intense, with various logistics equipment including palletizers, carts, forklifts etc. encountering people serving production lines,” he said in a statement. “Autonomous mobile robots from Mobile Industrial Robots appeared to fit the best in this plant.”

Next year, FORVIA said it plans to integrate MiR’s software management system, MiR Fleet, into the company’s enterprise resource planning (ERP) system.

“Mobile robots help us bring more discipline to the shop floor and make our production processes more stable and reliable, especially important is stability for operating all three shifts,” Horáček added. “What we appreciate most about these robots is their autonomy, meaning they move freely on the shop floor without any specifically needed equipment.”

MiR robots increase safety, productivity

MiR was founded in 2013 in Odense, Denmark and was acquired by Teradyne in 2018. In 2022, it merged with AutoGuide Mobile Robots, which is also owned by Teradyne. The company makes a range of mobile robots designed for manufacturing, logistics, and warehouse operations. The company said it has nearly 200 distributors around the world and system integrators in 60 countries.

In addition to its headquarters in Odense, the company also has regional offices in Holbrook, New York, San Diego Calif., North Reading, Mass., Georgetown KY, Singapore, Frankfurt, Barcelona, Tokyo, Seoul and Shanghai.

MiR said its robots improve safety within a warehouse, increase productivity, and have a strong return on investment. It noted that FORVIA made their made money back in less than two years at the Písek plant.

FORVIA at CES

At CES 2023 this week, FORVIA held a press conference where it highlighted the technology it is developing.

For more on the show, check out Robotics 24/7's special coverage page.

Article topics

Email Sign Up