Human workers have the experience and knowledge for complex tasks such as grinding and polishing, but robots can bring consistency and precision, freeing those workers for supervision and quality control. GrayMatter Robotics today said it has raised $20 million in Series A funding. The Los Angeles-based artificial intelligence and robotics startup plans to use the investment to expand its team to meet rapidly growing customer demands.

“We are improving shop workers' lives, enhancing their productivity, and enabling them to focus on higher-value tasks,” stated Ariyan Kabir, co-founder and CEO of GrayMatter Robotics. “Manufacturing drives our economy, and without automating surface finishing and treatment, there is a significant risk the global economy may suffer due to the increasing labor shortage.”

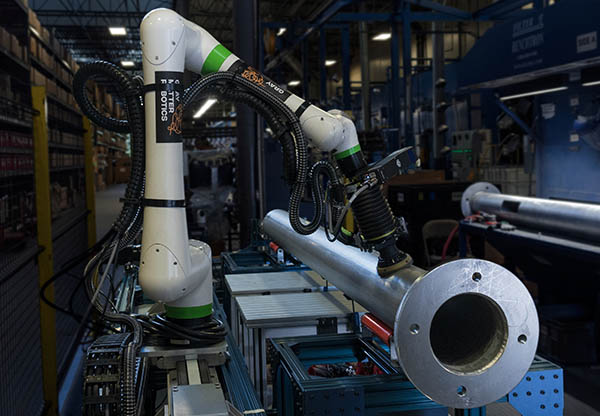

GrayMatter said it delivers smart automation for tedious and ergonomically challenging tasks. The company bundles its proprietary AI software with off-the-shelf robots, sensors, and tools. It offers application-specific systems through a robotics-as-a-service (RaaS) model.

In October 2021, the National Science Foundation (NSF) awarded the company Small Business Innovation Research (SBIR) Phase 1 and Phase 2 grants to develop the core technology behind its product. In January, the Advanced Robotics for Manufacturing (ARM) Institute funded two projects involving GrayMatter Robotics.

GrayMatter improves robot efficiency

Everything from football helmets to aircraft parts are currently smoothed and finished by hand, but this can cause repetitive stress injuries and expose workers to hazardous fumes, noted Kabir.

The surface finishing market is worth more than $100 billion in wages in the U.S., but manufacturers are facing labor shortages, he told Robotics 24/7. “There are about 9,000 robots compared with more than 1.5 million people involved with surface treatment in the U.S., but the latter is shrinking,” Kabir said.

Understanding how to do things such as removing material consistently from a complex, curved surface is difficult for most robots, he added. AI and human instruction are changing that. GrayMatter Robotics' technology enables robotic cells to improve quality and efficiency for high-mix, high-variability manufacturing, he claimed.

“We received investment because we've developed solutions with real commercial value,” said Kabir. “We're not just building technology for the sake of building technology. We looked at customer requirements and walked backward. This is not a general-purpose AI, and we keep iterating for ongoing improvement.”

“Our system doesn't need a CAD model or complicated programming; once it has understood the materials and process, it can program itself,” he said.

“We are a next-generation automation company shaping the future of work with smart robots,” said Brual Shah, co-founder and chief technology officer of the company. “Automating surface finishing and treatment applications for mission-critical production environments poses some extremely challenging engineering problems in AI and robotics.”

“It is fascinating for our team to see how our day-to-day work is immediately impacting a wide range of industries, from recreational equipment to aerospace,” Shah said.

Robots now able to meet industrial demands

GrayMatter Robotics said it is helping transportation, recreation, defense, and other general manufacturing industries and counts Fortune 100 companies among its customers. It works directly with them to evaluate their processes and identify the best solutions for their needs, said Kabir.

BEGA North America is an architectural lighting provider in Carpinteria, Calif. It wasn't sure robots could do the job—until it tried GrayMatter's Scan&Sand product.

“Our biggest concern was that our part mix is very high,” said Jon Coners, Sr., manufacturing manager at BEGA North America. “It seemed like a very daunting task to automate such operations.”

“Scan&Sand has the ability to work on a component or a group of components and have really [an] only one-button operation that is very simple,” he said. Coners added that users don't have to worry about having a fixed setup; “you can move parts around, and the robot will look again!”

“This was our first foray into robotics,” said Coners. “We had to have a partner that will be there for us, and GrayMatter has stepped up to the plate. GrayMatter is a partner with us, not just a vendor.”

GrayMatter to apply investment to new hires

Bow Capital led GrayMatter's Series A round. Existing investors from its $4.1 million seed round, including Stage Venture Partners, Calibrate Ventures, B Capital Group, Pathbreaker Ventures, OCA Ventures, and 3M Ventures, also participated. New investors included Swift Ventures.

“We're excited to invest in GrayMatter and its highly innovative team of AI experts,” said Murray Rode, general partner at Bow Capital. “We see enormous potential in GrayMatter’s solution to automate ergonomically challenging tasks to improve shop floor productivity and consistency, lower operational costs, and increase throughput while creating a safer workplace and promoting sustainability by reducing waste.”

While COVID-19 is no longer an obstacle to getting investment, market conditions and expectations have been shifting over the past three to four months, Kabir acknowledged. The oversubscribed round demonstrated interest in real-world applications and the urgency of labor shortages, he noted.

“Investors witnessed how we are addressing pain points during customer site visits,” said Kabir.

“Customer demand has never been higher for robotics and automation solutions, helping manufacturers improve productivity; obtain cost savings; and provide consistent, high-quality performance,” said Adi Leviatan, president of 3M's Abrasive Systems Division. “Reinvesting in GrayMatter Robotics aligns with 3M’s efforts to deliver easy-to-use automated abrasive processing systems that address the challenges posed by high-mix manufacturing operations.”

GrayMatter said it is hiring across a wide range of roles to meet North American customer demands, expand operations, and accelerate the development and deployment of the next-generation AI and robotic systems.

“We're growing from 14 to close to 50 people over the next nine months,” said Kabir.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up