Wearable and assistive technologies such as exoskeletons promise to redue worker strain. However, measurements of success have not yet been standardized. HeroWear LLC today announced its Exo-LiFFT tool, an interactive calculator to assess exoskeleton effectiveness.

“If we can identify the right places to deploy exoskeletons, then they can reduce injury risks as well as bodily discomfort, which impacts workers on the job and at home,” said Karl Zelik, chief scientific officer of HeroWear. “Exoskeletons may also help improve worker recruitment and retention, which have been costly pain points for employers amidst the labor shortage.”

Nashville, Tenn.-based HeroWear is developing a suite of assistive clothing to reduce fatigue and physical strain on workers. The company developed its first product, the Apex, with the Center for Rehabilitation Engineering and Assistive Technology (CREATE) at Vanderbilt University.

Study finds exoskeleton value

Companies have struggled with musculoskeletal injuries, which lead to missed work and accelerated retirement among skilled workers, said HeroWear. Overexertion is the primary source of lower back pain and injury, which accounts for 38.5% of work-related musculoskeletal disorders, according to the U.S. Bureau of Labor Statistics.

Zelik, who is also an associate professor of mechanical engineering at Vanderbilt, was the lead author of a study assessing how much technology can relieve workers. The six-person research team included Zelik and Matt Marino, director of ergonomics and human performance at HeroWear, as well as another Vanderbilt representative and industrial engineers from Auburn University.

HeroWear and Vanderbilt said they have been deeply involved in exoskeleton research, design, and translation. They have also worked to develop industry standards with members of the ASTM International standards committee.

Exoskeletons could potentially reduce workplace back injuries in material handling by 20% to 60%, found the study, which was published in the Journal of Applied Ergonomics.

“This is a critical advancement because work-related injuries to overburdened workers are a major factor contributing to the current dynamics in the labor market,” said HeroWear in reference to shortages during the COVID-19 pandemic.

HeroWear develops Exo-LiFFT

Exoskeletons are now being used daily in factories, warehouses, construction sites, and other workplaces around the world to relieve physical strain on overburdened workers. HeroWear said it developed Exo-LiFT with the recent study in mind.

“With the help of exo-technology, workers in the future could have fewer injuries, less chronic pain, and careers won’t be cut short,” Marino said. “A tool like Exo-LiFFT can go a long way in showing the impact these types of workforce wearables can have on improving people’s lives.”

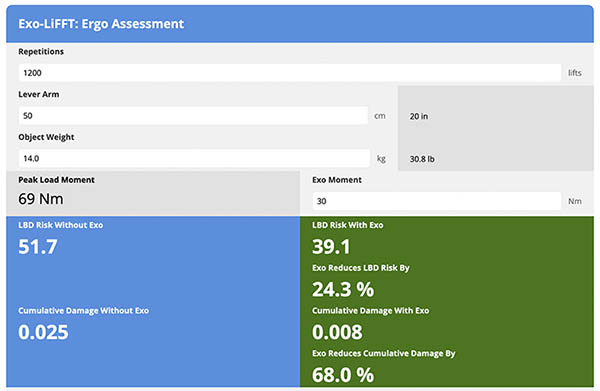

Exo-LiFFT is designed to enable safety professionals and researchers to quickly and easily assess the effect of exoskeletons on back injury risk without the need for costly and time-consuming experiments, said HeroWear. This can reduce the time needed for biomechanical assessments of back exoskeletons from months down to minutes, it claimed.

The tool also provides an evidence-based way to estimate injury risk reduction, the company said.

“At Toyota, we have relied heavily on new ergonomic assessment tools to support our teams in identifying processes on our manufacturing lines that would benefit from shoulder exoskeletons being deployed as personal protective equipment,” said Aaron Sparks, safety project engineer at Toyota North America. “As we begin to investigate and deploy back exoskeletons, it’s incredibly exciting—and a major relief—to see similar tools being developed to support with the identification and deployment.”

The global market for wearable robotics will grow at a compound annual growth rate (CAGR) of 43.48% from 2018 to 2028, reaching $5.4 billion, projected BIS Research.

Similarly, Fortune Business Insights predicted a CAGR of 43.6%, with the market expanding rom $952.5 million in 2022 to $11.9 billion in 2029, and Fact.MR forecast a 30.3% CAGR from $282.88 million in 2022 to $3.9 billion in 2032.

“We have over 100 facilities across the country where workers are lifting and moving products,” said David Brodie, ergonomist lead at Cargill. “New assessment tools like Exo-LiFFT will help us identify where the best opportunities are in our operations to support workers.”

“This tool allows us to interact with vendors like HeroWear to determine where their exosuits may provide the level of support needed to reduce the risk for our workers,” he said.

Article topics

Email Sign Up