Honeywell International Inc. today announced the spring 2022 release of enhancements to Honeywell Forge, its enterprise performance management (EPM) offering designed to help customer accelerate the digital transformation of their operations. The company said Honeywell Forge EPM for Warehouse will help organizations lower costs through new visibility, insights, monitoring, and automation across their supply chains.

“Our new EPM for Warehouse offering brings a scalable, secure, and cloud-based solution to help distribution centers accelerate their productivity, predictability, and transformation strategies,” said Kevin Dehoff, president and CEO of Honeywell Connected Enterprise. “We are proud to also introduce several enhancements to our existing software solutions across the aerospace, smart buildings, and industrial sectors which will enable enterprises to optimize asset performance and drive operational savings.”

Charlotte, N.C.-based Honeywell supplies aerospace products, control technologies for manufacturing and construction, and performance materials globally. The Fortune 100 company said Honeywell Forge is built on a native edge-to-cloud, data-driven architecture.

EPM for Warehouse provides visibility

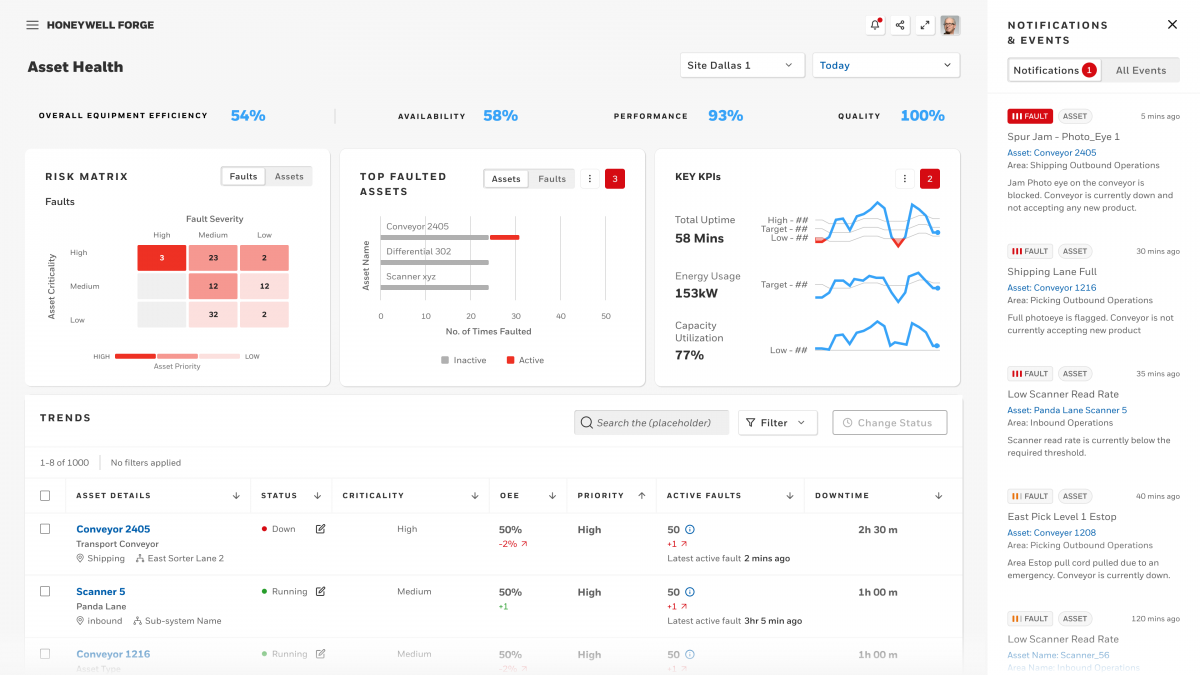

Honeywell said the EPM for Warehouse Essentials Bundle provides organizations with two modules that provide real-time visibility across their warehouse operations. It also includes advanced analytics to reduce unplanned downtime, address recurring challenges, and automate legacy processes.

The Site Operations module has a dashboard that indicates how sites are performing against plan and can help managers identify repetitive bottlenecks and proactively address issues that may affect performance, said the company. The interface, which is optimized for tablets, enables enterprise benchmarking, monitors areas such as picking and shipping and makes recommendations to achieve daily targets.

In addition, customers can use the Honeywell Forge Connect edge feature to connect devices and integrate with standard warehouse systems.

“The environment in today’s retail, e-commerce, and supply chain logistics has led to an unprecedented demand for increased fulfillment performance,” said Doug Henschen, vice president and principal analyst at Constellation Research.

“Nonetheless, awareness towards the state of the warehouse workers, their safety and their wellness and productivity drive innovation in automation,” he said. “It’s encouraging to see Honeywell Connected Enterprise embracing this vision and supporting automated action through the Honeywell Forge portfolio of SaaS [software-as-a-service] applications.”

A second module called Asset Performance Management (APM) for Warehouse enables maintenance teams to quickly collaborate on equipment performance problems and shares remediation recommendations.

Operations and maintenance managers can use rules-based analytics and asset modeling to identify and analyze trends. Predictive maintenance and asset health monitoring offer new capabilities to improve operational performance and increase asset availability, said Honeywell. Pilot users have experienced reductions in unplanned downtime and overtime costs by predicting failures, it said.

Honeywell enhances existing software

Honeywell also released updates to other software across the aerospace, smart buildings, and industrial sectors.

- The new Honeywell Forge Pilot Connect mobile app is designed to improve fuel savings while engaging flight crews in company-wide sustainability and efficiency initiatives. The app works with Honeywell Forge Flight Efficiency to provide pilots with briefing information like historic fuel averages, debriefing information like trajectory analytics, and customizable key performance indicators (KPIs) and targets.

- Honeywell Forge Predictive Maintenance provides near real-time visibility into asset health and performance, and service cases in order to prioritize asset issues based on safety and operational and quality risks.

- Sine occupant experience solutions provide frictionless access to buildings via mobile Bluetooth. Other improvements include new scheduling and capacity-planning features along with occupant experience enhancements such as better feedback, information, and wayfinding.

- Unisim Design now allows users to gather KPI insights from a single dashboard and expand downstream capability in a solution for green hydrogen modeling. It supports Green H2, CO2 transportation, thermo expansion, and the REFPROP and DIPPR standard models.

- The Honeywell Forge Inspection Rounds offering has added features including the ability to record audio/voice during task execution and in-app, map-based route guidance via ArcGIS integration. Other additions include audit trail logging, monitoring application usage, configuration changes, active directory, and federated login integration.

- For operational technology (OT) cybersecurity, Honeywell is rolling out a Cyber Care product for its Process Control Network (PCN) Hardening Service. After initial hardening services to help industrial companies reduce their OT attack vectors, continued on-site Cyber Care visits will assist companies in maintaining networking hardening benefits and stay better protected against cyber incidents.

“Honeywell continues to build and enhance connected solutions so our customers can succeed with their digital transformation, efficiency, and sustainability goals,” said David Trice, chief product officer and general manager of Honeywell Connected Enterprise. “Our new EPM for Warehouse solution will enable our customers to meet pressing challenges in the supply chain environment with an operational SaaS system of record that leverages new insights from OT assets from across the enterprise.”

“We also believe these enhancements to our existing offerings will drive more efficiency and add new operational capabilities across the industries we serve,” he said. Prospective customers can find more information about Honeywell's spring release and request a demonstration at the company's Web site.

Article topics

Email Sign Up