Did you know that there is a global plastic sorting crisis? In fact, only about 9% of all plastics are recycled each year. The rest end up in landfills or the ocean, where they cause enormous environmental damage. But there is hope! Thanks to advances in machine learning and robotics, we may be able to solve this crisis in the near future.

About 8 million tons of plastic waste goes into the world's oceans every year, according to a 2019 National Geographic report. While governments debate how to address the problem, the global market for solvent-based plastic recycling could reach $965.1 million by 2030 at a compound annual growth rate (CAGR) of 5.9%, predicted Research and Markets.

This past week, MIT noted that new catalysts could break down plastics for reuse, but first, items must be collected and sorted. Robotics and machine learning are helping to sort plastics faster and more efficiently than ever before.

Is robotic sorting the answer?

Manual processing of waste is dull, dirty, and dangerous, making it ideal for automation. Several companies have developed robots to help with the process.

For example, ABB Robotics has demonstrated a workcell with its IRB 1200 industrial system and YuMi collaborative robot that can identify and sort different types of plastics. The cobot has two arms and can move them independently, and it can be wheeled to workstations as needed.

“This isn't the only solution, however,” said Nina Faunti, a technical writer at Lia Help and Essayroo. “In some cases, it may be more efficient to use machines that can identify and separate plastics by their shape or color.”

She cited the example of the Votechnik ALR-4000, which uses a KUKA robot to process electronics waste and extract valuable materials.

AI, machine learning address plastics sortation

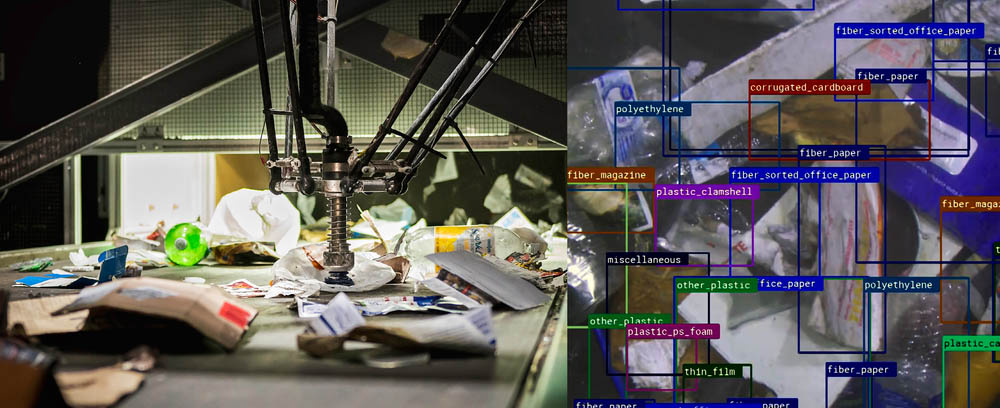

Among the latest technologies being applied to plastics recycling are artificial intelligence and machine learning. They are used to visually identify different materials and manipulate items with robotic grippers. In addition, machine learning enables robots to get better at doing things over time.

The combination of AI and robotics enables human workers to focus on higher-level cognitive tasks while removing them from front-line risks. They are able to speed up the sorting process while still maintaining accuracy. So far, they have been able to successfully sort different types of plastics, including those that are dirty or covered in grease.

“In addition to machine learning, robotics is also playing an important role in the sorting process,” explained Ben Turner, a journalist at State Of Writing and BigAssignments. “Robotics involves the use of machines to carry out tasks that would otherwise be difficult or impossible for humans to do. This includes tasks such as moving heavy objects and working in dangerous environments.”

One example of a combination of robots and machine learning is AMP Robotics Corp., whose Neuron system uses computer vision to recognize materials early in the recycling process. The company said its Cortex robot can sort up to twice as fast as manual processing, and it recently marked the deployment of 50 of its systems with Waste Connections Inc.

In addition, ZenRobotics has created its Heavy Picker system, which uses AI in the initial stages of sorting, with robots taking care of picking at later stages.

Plastics recycling automation pros and cons

There are a lot of benefits to using machine learning and robotics for sorting plastics. They can work faster than humans, which means that more waste can be sorted per day. This is especially important when there aren't enough volunteers available or willing to do the job by hand.

In addition, machines don't need breaks like people do, so they can work around the clock if necessary. However, this also brings up one possible downside of using machines: They may not always be 100% accurate in identifying different types of plastic.

What's more, machines can be expensive. Some people think that it would be cheaper to hire humans than to buy an expensive robot for sorting plastics.

There are also some other concerns. For example, what happens if the machine breaks down? Many robotics suppliers offer contracts with specific service-level agreements (SLAs), especially those with a robotics-as-a-service (RaaS) model.

There's no denying that sorting plastics by hand is time-consuming and costly. That's why companies like ABB and AMP Robotics are working on ways to speed up the process with robots. No single approach has yet solved the problem.

Industrywide adoption will take several years, but with technology evolving quickly and so many people working hard on such projects, there's little doubt that they can help recycle more plastics.

About the author

Jenny Han is a technology writer and journalist at Essay Writing Service and State Of Writing. She said she works hard to help businesses find solutions for their problems and to help spread the word of the latest technology developments. Han also writes for Research Paper Writing Service.

Article topics

Email Sign Up