Humatics Corp. this month announced that it will show what it described as an “industry-first” in-motion engine assembly application with multiple robot arms working concurrently in the same pitch at Automate 2023.

The Waltham, Mass.-based company said the ability to automate tasks that were previously not possible with robotics will open up new levels of cost reduction, quality control, and profitability for automotive and aerospace manufacturers.

“Humatics engineers highly-precise movement with its Microlocation technology and continues to support applications such as in-motion assembly that help organizations expand their use of robotic technology to increase profitability,” said Ronald Ranaldi, senior vice president of Humatics, in a release.

“Witnessing the in-motion capabilities of advanced robotics live often leads organizations to expand their understanding of what is possible and to quickly identify new applications that can significantly benefit their business,” he said.

Humatics microlocation to enable tool use on moving parts

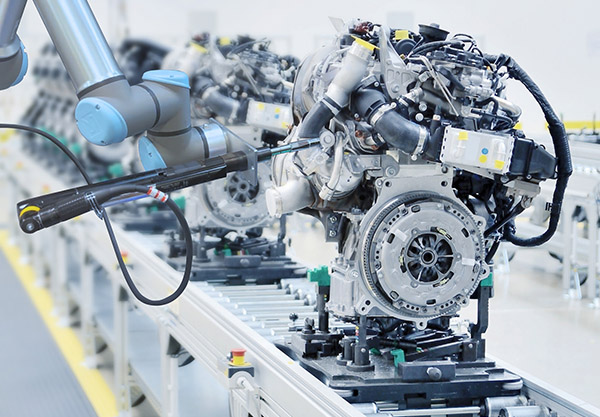

In its demonstration at Automate, Humatics will show two independent and different-model Universal Robots (UR) collaborative arms equipped with Atlas Copco PF 6000 assembly tools. They will concurrently torque bolts on an engine block as it actively traverses the work space on an autonomou smobile robot (AMR) from Mobile Industrial Robots (MiR).

The company said it is enabling the UR arms to be aware of the engine position in three-dimensional space. This empowers the cobots to interact with the moving engine, even as the engine varies its location each time it passes the robots, it noted.

“Universal Robots is proud to include Humatics Corp. as a partner in our UR+ ecosystem,” stated Joe Campbell, senior manager of applications development and strategic marketing at Universal Robots. “The Humatics Microlocation technology, Milo, fully leverages the UR PolyScope platform and expands the range of labor-intensive, unergonomic applications that can be automated.”

Humatics will show its live, in-motion multi-arm torquing use case in Booth 5415 at Automate, which will be in Detroit from May 22 to 25.

Editor's note: For more about Automate 2023, visit Robotics 24/7's special coverage page.

Article topics

Email Sign Up