Unlike factories, where many types of robots from different vendors may work together, most warehouses and distribution centers at an earlier stage of automation adoption. As fleets of mobile robots grow, the need to effectively manage heterogeneous environments is also growing. Meili Robots recently released a report on interoperability.

“Many in industry have talked about wanting to expand applications of robots, but they've been put off by interoperability issues or concerns on how to combine different systems,” said Aldus von der Burg, founder and CEO of Meili Robots. “They don't want to juggle between three fleet management systems. I haven't seen fully diversified fleets yet outside of a hospital, but people are talking about it.”

Market challenges

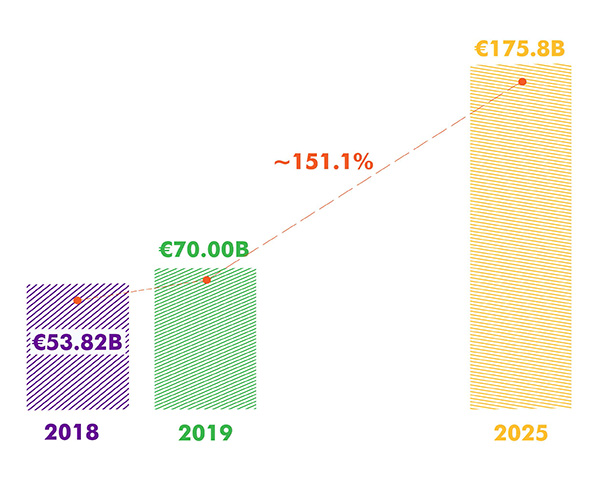

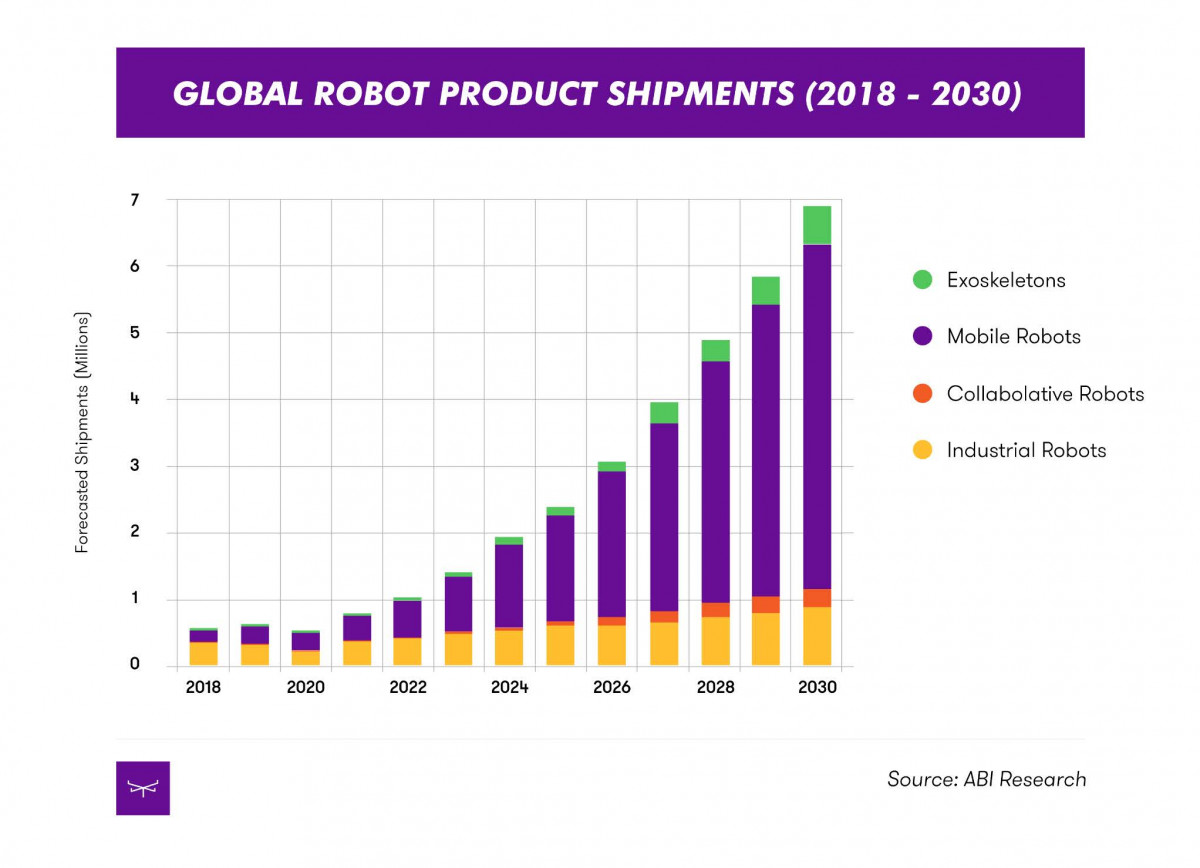

The global market for manufacturing and non-industrial robots is expected to reach €175.75 billion ($212.34 billion U.S.) by 2025, according to ABI Research. Sales of service robots—including systems for logistics, healthcare, military, and field applications—rose by 61% in 2018, with more than 271,000 units being shipped.

Companies are investing in automation for inventory management, procurement, assembly, and transportation, among other applications, said Meili Robots. With more companies buying robots, suppliers are unable to keep up with the growing demand, it added. As a result, businesses will deploy different brands of robots, leading to more diverse technology portfolios.

According to the industry report, problems can arise when multiple systems — particularly automated guided vehicles (AGVs) and autonomous mobile robots (AMRs) — are used in the same environment. Coming with different operating systems, these robots may not be able to communicate with one another. This can even lead to collisions, accidents, and delays in operations.

“Now, logistics companies will be able to buy hundreds, if not thousands, of different palletizing and pick-and-place robots before interoperability becomes a major issue,” said Aaron Prather, a senior technical advisor at FedEx Express. “However, when it comes to mobile robotics, interoperability is already becoming an issue.”

With the increases in demand and specialization of robotics, companies must find ways to improve communication and coordination, said Meili Robots.

Technology trends

The Industrial Internet of Things (IIoT) is among the developments that could aid businesses with robot adoption and management, the report said. With cheaper sensors, universal connectivity and 5G networking, and the application of artificial intelligence, robotics users could gain timely insights into critical processes. Data collected from stationary and mobile sensors and analyzed with AI could drive greater efficiency, flexibility, and productivity, said Meili.

“A few companies have tried using robots from more than one vendor,” von der Burg told Robotics 24/7. “They want to avoid bottleneck inefficiencies. One pharmaceutical firm has been using AGVs and is looking to diversify its fleets with AMRs and robots for outdoor deliveries.”

The report includes a case study about Project START, which involved testing and adjusting Mobile Industrial Robots ApS's fleet management system at a Danish hospital.

“In the hospital, AGVs can handle laundry or heavier items in hallways, but it was also using AMRs to deliver supplies to rooms and smaller areas,” said von der Burg. “It's now thinking of using other robots for disinfection or automating beds.”

Multiple applications, groups for interoperability

“There is also the potential of UGVs [unmanned ground vehicles] at the airport for handling luggage and then other robots inside for supplies or security,” von der Burg said. In addition, Meili Robots examined how modern robots can help reduce carbon footprints for environmental sustainability.

Companies such as Meili Robotics, Freedom Robotics, and inOrbit are working to tackle the interoperability challenge, as are organizations such as the Robot Operations Group and working groups at the Association for Advancing Automation (A3), the Advanced Robotics for Manufacturing (ARM) Institute, and MassRobotics.

Meili Robots said it is developing the next generation of mobile robot fleet management, called Meili FMS. It is capable of handling different kinds of AMRs and AGVs, claimed the Copenhagen-based company. The product can help control traffic, empower interoperability, and facilitate allocation of automated tasks, said Meili.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up