Like many other conferences, the annual IOT World conference went online, kicking off this week. The looming threat of COVID-19 and its widespread impact are reflected in the show's content lineup.

Sam Lucero, Sr. Principle Analyst, IoT Services & Technologies, Omdia, said the impact of COVID 19 on IoT is complex, but not all bad. He characterized the nature of the projects as “more of a delay than derailment.” On the bright side, “the virus situation demonstrates the value of connected solutions in new areas.”

In the opening keynote on August 11, Zack Butler, Informa Tech, Portfolio Director, shared results from a result survey.

“It's really encouraging to see that 24% [of the respondents] highlighted that executive support [for IOT deployment] has increased, and 19% highlighted that the pilot project concept was a success,” he noted. “We must not forget there’s a vast range of challenges in IOT deployment. Security remains a big concern.” Other hurdles include “lack of expertise in deployment and interoperability with legacy systems.”

Data is the New Goldmine

Despite COVID's impact, Lucero thinks the IOT uptake will continue. The world is expected to see “7.4 billion devices cumulatively in 2019 to 20.3 billion devices in 2025, with a compound annual growth rate of 18.3%,” he said.

Certain industries are now seeing higher activities, caused by the virus outbreak. Connected healthcare solutions, wearable devices, and remote patient monitoring devices are among them.

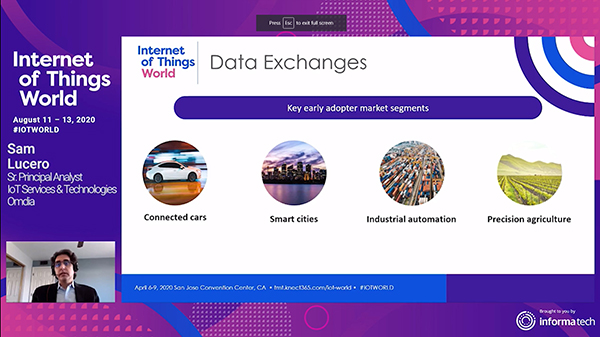

The new frontier is the exchange—or, to put it more bluntly, sales—of data for IOT purposes. Over time, regular and autonomous car makers will amass a vast about of telematics (telecommunications and vehicular data), rich with insights revealing driver behavior, accident frequency, and other info. These, Lucero pointed out, are of immense value to insurance carriers, repair service vendors, and smart city developers, setting up a fertile ground for data commerce.

“Doing in in compliance with privacy regulations is the key,” Lucero said. But even that may not necessarily put the skittish consumers at ease. Inevitably, there'll be a tug-of-war between the consumers who want to stay below the radar (so to speak) and the data merchants hungry for more.

If data is the goldmine, then data privacy is the Wild West with murky laws.

Digital Twins Meet Physical Source

Seshagiri Marellapudi, head of MindSphere IIoT Cloud Platform, Siemens, also pays attention to data, as the backbone of Industry 4.0 transformation. In his presentation, he said, “It's all about how you pull the data from your industrial systems, what you can do with it, and how you produce actionable insights.”

MindSphere, he proposes, is a good solution to connect your physical device to the digital counterpart to create a closed loop digital twin lifecycle.

In the digital simulation of a factory's operation, for example, “there are often opportunities to improve the production line in reality. Can you create these changes and run what-if analyses in simulation to see if they will work?” he asked hypothetically.

AI with a Purpose

In the panel discussion moderated by Lucero, Teresa Tung, Managing Director, Accenture; Dr Ashwani Dev, Data Science Officer, Halliburton; and Jonathan Weiss, VP, Software AG, discussed the role of data analytics and AI applications.

“Identifying the capability that will improve business, like asset uptime or safety,” is the key, according to Tung. “AI is there to augment that process. You don’t start with AI for its own sake,” she cautioned.

Aside from data scientists, the domain experts must also be involved. “Like the connected worker, the oil and gas expert— They will help you label the data correctly; they will check the results to see if they are correct. The human aspect of the domain is important, not just the Python code,” she said.

“In manufacturing, for example, there's a lot of data coming out. Without domain knowledge, it’s hard to understand what’s important,” added Weiss.

Many are now considering robust edge devices with built-in processing power to cutdown cloud expense. Weiss cited the case of IOT-enabled wind turbines as an example. “Each of these 5,000 wind turbines generate 15TB of data a day. The cost will be astronomical to process that in the cloud,” he noted. “So it pushes the processing to take place on the edge, then just sending the anomalies to the cloud.”

IOT World Virtual continues through August 13.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up