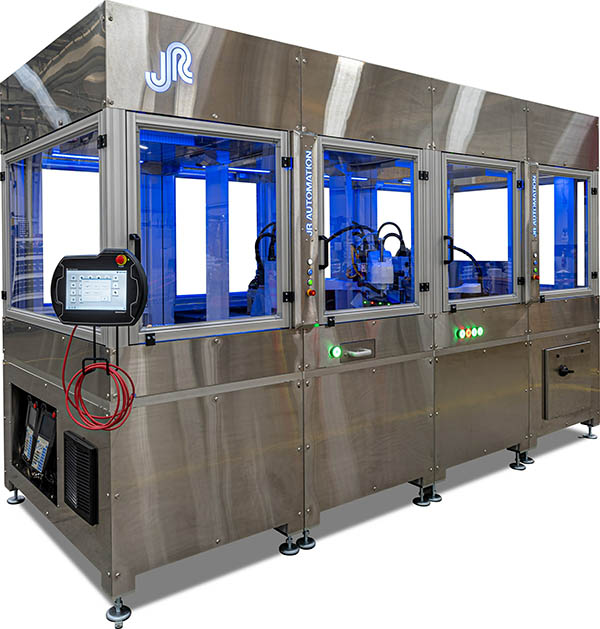

JR Automation released a new automation platform at ATX West earlier this week designed for manufacturers looking for flexibility.

“Built with standardized, pre-designed modules, FlexChassis can be configured to meet a very wide range of manufacturing objectives for assembly and process applications,” the company said in a release.

The Holland, Mich.,-based company added that the platform was designed to be used in the medical, consumer goods, and electronics manufacturing markets.

Assembly capabilities include:

- Ultrasonic welding

- Riveting

- Screwing

- Snap fit

- Gluing

- UV gluing

- Decorating,

- Heat Sealing,

- Joining dissimilar materials

Material joining capabilities include:

- Heat/ultrasonic foil sealing

- Laser tacking

- Laser ablation

- Laser or ultrasonic cutting and die cutting

FlexChassis’ configurability enables a range of use cases

FlexChassis also includes full digital control and process monitoring. Additionally, linear motors give FlexChassis speed, accuracy, and operational flexibility with multiple configurations through a human machine interface recipe selection.

From UL and CE to FDA and Gamp5, the FlexChassis design can be tailored to match specific production requirements. For clean manufacturing needs, FlexChassis meets various ISO classes.

“We recognized a market need for an automation platform that allowed for high flexibility without requiring a significant amount of upfront engineering; lowering cost, minimizing risk and shortening delivery,” said Greg Herman, Jr Automation business development manager, in a statement.

“FlexChassis was engineered from the ground up taking into consideration the needs of our medical customers while offering the flexibility our customers expect,” said Mick Trompen, JR Automation medical market chief engineer.

JR Automation was founded in 1980 and has 28 manufacturing facilities in North America, Europe, and Asia. It was acquired by Hitachi Ltd. in 2019.

Article topics

Email Sign Up