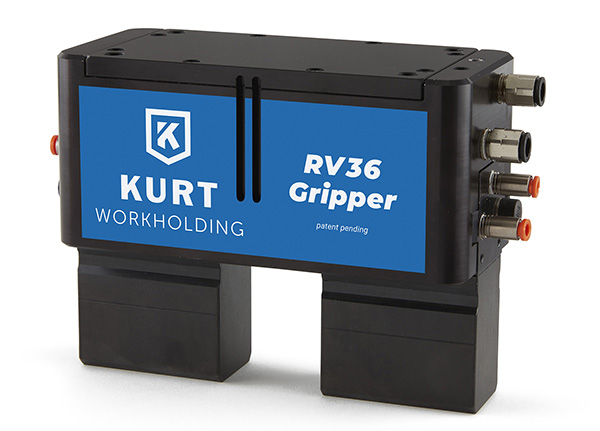

Kurt Workholding last month announced the launch of its new RV36 Robotic Gripper—a two-finger parallel gripper featuring a patent-pending design that allows automated finger/end effector changes without changing the gripper body itself. Quick change jaws allow customers to save on gripper-body expenses and create greater part-holding flexibility, said the Minneapolis-based company.

“We saw an opportunity to increase gripper automation efficiency and to save money for customers with a quick-change finger system using pull-stud technology,” said Steve Kane, a sales and marketing manager at Kurt Workholding. “Our unique product is the first robot gripper with the ability to automatically change gripper fingers and the ability to accommodate an endless variety of end-effector options.”

Kurt Workholding has provided machine vises and workholding technology for more than 60 years. Designed, manufactured, and assembled in the U.S., the company's line of workholding products serves the machining industry. Kurt is known for its angle-lock design vises, and it has expanded into a variety of other areas including five-axis vises, workholding towers, automation, and quality control. Kurt Workholding also provides manufacturers with custom engineered systems to help them maximize efficiency and quality.

The completely employee-owned company is a division of Kurt Manufacturing, and its facility includes multiple workstations, production lines, and integrated automation with in-house design, engineering, production, assembly, and shipping.

Kurt RV36 features

The compact Kurt RV36 Gripper comes standard with integrated electronics featuring sensors that ensure fingers and parts are in place and ready for production.

High-strength aluminum alloy keeps gripper weight to a minimum, while a hard-coat finish reduces wear and increases life in the field. A smaller gripper size allows easier storage where space is a premium, according to Kurt Workholding.

The Gripper’s double-acting piston allows for maximum clamping and un-clamping force.

Customers can choose from carvable aluminum or steel finger options that can be machined to work in a variety of applications. Additional finger sets are also sold separately.

Kurt RV 36 Grippers will be available in August at kurtworkholding.com.

Article topics

Email Sign Up