Machina Labs Inc. this week emerged from stealth and announced that it has closed a $14 million Series A round of financing, bringing the total raised to $16.3 million. The company said it is working on applying robotics and artificial intelligence to design and manufacturing. Machina Labs plans to the funds to grow its team in Los Angeles and to expand research, development, and manufacturing capacity to meet rapidly increasing customer demand.

“Manufacturing must be reinvented to keep up with the pace of change in this highly competitive market,” said Edward Mehr, co-founder and CEO of Machina Labs. “We're excited to finally reveal Machina Labs' manufacturing platform, which combines the latest advances in robotics and AI to democratize access to rapid manufacturing so that anyone with a great idea can manufacture parts quickly, efficiently, and cost-effectively.”

“These software-defined, robotic facilities are the factories of the future, and we're thrilled to have our investors on board to help us get there,” he said.

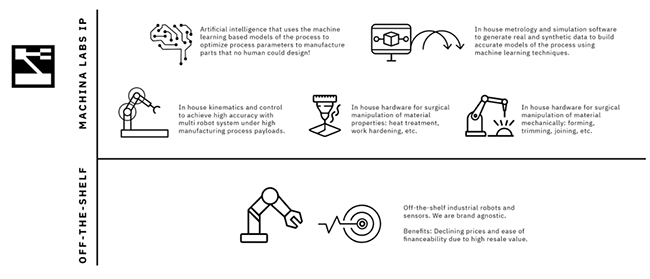

Founded in 2019, Machina Labs said it is developing on-demand, software-defined factories of the future. The startup said it is using AI and robotics to introduce flexibility to manufacturing. Its stated goal is to reduce lengthy design lifecycles and enable greater agility at a significantly lower cost in highly competitive markets.

Machina Labs offers agility for manufacturing

The manufacturing market is ripe for disruption, according to Machina Labs. Unlike the IT industry, which has embraced rapid iteration and a fast design lifecycle to accelerate innovation, factories continue to rely on processes that are rigid, slow, and expensive, it said. In some industries, the design lifecycle can be as long as seven years — a major hurdle in product development.

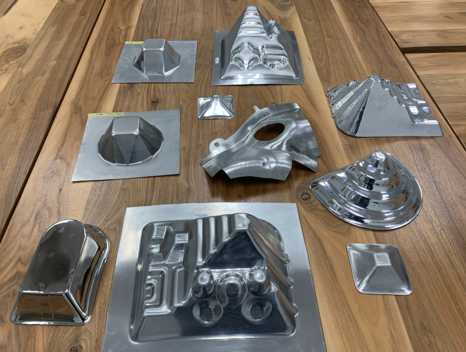

In the sheet metal forming industry, a current area of focus for Machina Labs, dies and stamping machines are multi-million-dollar investments. The design-specific tooling costs to set up a stamping line can reach up to $1 million for a single design. These impediments put manufacturing largely beyond the reach of all but a select few industrial giants, said the company.

Similar to an experienced craftsman using a hammer to create sheet metal parts, Machina Labs said its robots use AI-driven sensor data to incrementally manipulate sheet metal to form parts. The company claimed that its Los Angeles factory provides flexible, on-demand, software-defined manufacturing as a service to a variety of industries.

Machina Labs noted that the market opportunity in reinventing sheet-metal forming is significant. Based on an analysis of savings in material production, component manufacture, and product use, the company said its technology could save an estimated $12.3 billion per year in the U.S. when fully deployed.

RaaS and reshoring

Machina Labs said it can supporting rapid deployment and scale up with no upfront investments in tooling. It also enables the remanufacturing of parts and components that are no longer in production and for which machinery or dies are no longer available. A robotics-as-a-service (RaaS) model replaces capital expenditure costs while preserving and creating jobs, said the company.

In addition, Machina Labs said it can help businesses overcome supply chain problems by bringing production to the U.S. According to the U.S. Census Bureau, manufacturing has experienced a 60% increase in disruption during the COVID-19 pandemic — more than any other industry. This has triggered a push to move critical processes stateside.

However, using traditional factories for reshoring can introduce new challenges, such as higher-priced products because of companies' inability to take advantage of the cost efficiencies they enjoyed in other countries. Machina Labs said it can eliminate many of these supply-chain bottlenecks through its cost-effective, fast, and efficient manufacturing processes.

Machina Labs pilots in aerospace, defense

Some of Machina Labs' current customers are in the aerospace and defense industries. Having completed pilots with NASA and the U.S. Air Force, the company is now working on commercial engagements.

With NASA, the company said it is working to achieve optimal efficiencies in tank design — something not easily done using traditional processes. Machina Labs is also working on its vision to create factories of the future not just on earth, but also in space. It has begun work with NASA on using its technology for in-space manufacturing as a necessary precursor to a multi-planetary future.

With the U.S. Air Force, Machina Labs' technology is accelerating the development of composite molds and the production of parts in applications such as drones.

“The USAF is investing in disruptive technologies that generate leap-ahead capabilities and put us in a position to be agile and responsive to the war fighter’s needs,” the Air Force said in a statement. “We are excited about all technologies that make manufacturing, repair, modification, reclamation, and rework of aircraft and their associated components more agile, affordable, and faster. Robotic metal forming is most certainly one of those technologies.”

Other customers include the U.S. Department of Energy, Lawrence Livermore Lab, and several large automotive companies.

Investing in innovation, expansion

Innovation Endeavors led Machina Labs' Series A round, with participation from Congruent Ventures and Embark Ventures.

“We're living through a critical moment in manufacturing and expect much to change coming out of the supply chain madness that COVID instigated,” said Sam Smith-Eppsteiner, partner at Innovation Endeavors. “Manufacturers and end-product companies alike are looking for technology to help make them more efficient and adaptable.”

“While these two goals were historically in tension, Machina Labs unlocks both,” he said. “We see huge opportunities for Machina Labs to disrupt engineering and design for metal parts, making the process faster and more iterative. But we also believe that Machina will transform the production of parts for low- to mid-volume by reducing the manufacturing costs, time-to-market, and inventory holding costs for tooling.”

Innovation Endeavors is an early-stage venture capital firm that invests in data, leading-edge computation, and advanced engineering to transform industries, from agriculture and logistics to life sciences, transportation, and more. Its investments include AlphaSense, Blue River Technology, Fabric, Formlabs, Uber, and Vicarious Surgical.

Machina Labs is looking to expand its team in Los Angeles. Its employees have worked at organizations including SpaceX, Microsoft, Google, Northrop Grumman, and Stratasys. For a current list of job openings at Machina Labs, visit www.machinalabs.ai/careers.

Article topics

Email Sign Up