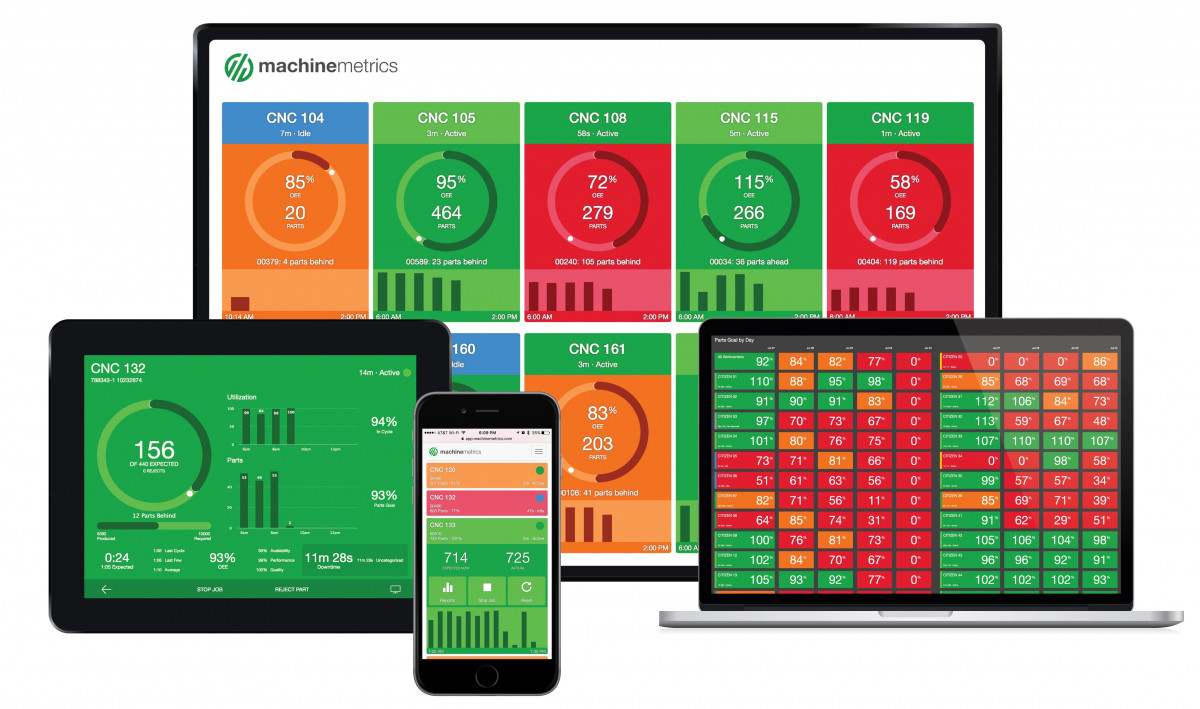

MachineMetrics earlier this month announced the availability of its Connector for Universal Robots (UR). The product, which is part of the UR+ program, is designed to give customers better access to data that will help them determine the health and performance of their cobots.

“Connecting to – and capturing real-time data from – manufacturing equipment is what enables our customers to quickly and easily understand their production performance and the health of their machines,” said Bill Bither, CEO and co-founder of MachineMetrics, “By connecting UR cobots to MachineMetrics, users can now gain real-time insights into cobot productivity, alert teams when issues arise, and remotely troubleshoot and diagnose issues to get the cobot back up and running.”

More on MachineMetrics

The Northhampton, Mass.-based company said it makes “the single platform to capture, manage, and analyze manufacturing equipment data.” Last year, it raised $20 million in its Series B funding round.

“Today, hundreds of manufacturers across global factories are using MachineMetrics as the foundation of their digital factories, leveraging plug-and-play machine data collection, real-time visualizations, predictive insights, and flexible APIs to optimize, adapt, and evolve their manufacturing processes no matter what the circumstances may be,” it said.

The company added that more and more manufacturers are turning to technology to modernize their factories.

“Extending the value of MachineMetrics to drive automation is the next generation of solution for manufacturers,” said Bither. “On its own, MachineMetrics can let the right person or system know at the right time what is happening to keep machines running. In an autonomous factory powered by MachineMetrics, machine data can trigger an action by a robot that feeds the bar into the machine without human intervention.”

Cobot adoption on the rise among manufacturers

Cobots are one of the most popular types of robots being bought, it argued, citing a recent report from Research Dive, which found that the global collaborative robot market is predicted to grow at a compound annual growth rate of 41.2% by 2026.

“Cobots deliver a cutting-edge solution that makes it easier than ever before to automate manual tasks such as the loading and unloading of materials and parts, leading to major productivity gains and boosting throughput with no additional headcount,” the company said. “But, like all machines, ensuring these cobots run to their potential is paramount to their success.”

MachineMetrics has been lauded by Universal Robots, with Christopher Savoia, regional head of the UR+ Ecosystem, saying the company is making it easier for manufacturers to decide to automate.

“Their unique ability to deliver real-time insights into the health and performance of UR collaborative robots means increased reliability, uptime, and productivity of automated work cells,” he said.

Article topics

Email Sign Up