As digital commerce and the on-demand economy grow rapidly worldwide, enterprises need help tackling labor challenges and expanding consumer expectations. Mobile logistics robots have emerged to enhance the efficiency of operations.

Autonomous mobile robots (AMRs) can include multiple sensors, control systems, and power supplies, as well as different configurations of software and manipulators. Such smart devices are serving a widening range of applications, from materials handling in manufacturing to customer service in retail.

Online and offline retailers adopt AMRs

Amazon.com Inc.'s Kiva robots have helped it speed the e-commerce order-fulfillment process from distribution centers to drop-off locations. Mobile robots also enable the company to fulfill orders with a remarkable degree of accuracy. Amazon Robotics is also working on other forms of automation.

Amazon's purchase of Kiva Systems in 2012 helped create the AMR category because Kiva's robots were no longer available to other retailers and logistics providers.

Other retailers, such as Walmart, Best Buy, and Shopify, have gained greater flexibility and visibility into their logistics operations with advanced software and mobile robots.

Walmart uses AMRs for floor cleaning and taking inventory. The company also uses warehouse automation and is working on autonomous vehicles and drone deliveries.

In 2019, Shopify acquired AMR provider 6 River Systems, but unlike Amazon and Kiva, 6 River Systems continues to sell robots to other customers.

Another example is inVia Robotics, which has developed an array of AMRs that can conduct various warehouse tasks, including cycle counting, inventory replenishment, and item verification.

Healthcare gets robot aides

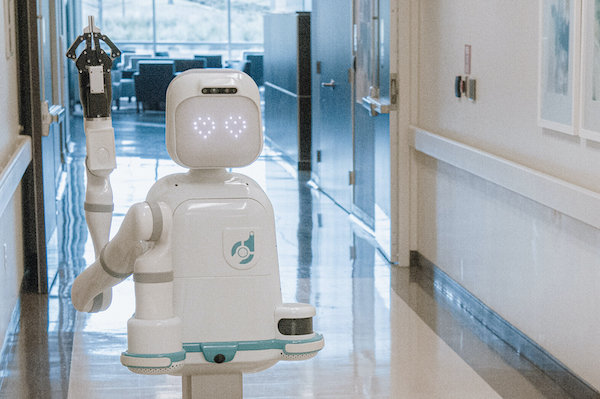

In addition to fulfillment centers and retail stores, hospitals are other dynamic environments that could benefit from mobile logistics robots. However, developers and suppliers serving the healthcare market must be aware of hygiene, privacy, and safety regulations. Robots can do everything from dispensing medications and assisting surgeons to moving materials or patients.

Moxi from Diligent Robotics is a mobile manipulator that can help retrieve supplies. Relay+ comes from Savioke, whose AMRs were first used in hospitality.

Aethon's Tug AMR can securely move pharmaceuticals, and UVD Robots supplies disinfection robots to fight hospital-acquired infections worldwide.

In Houston, the Texas Medical Research Innovation Institute has tested ABB's mobile, two-armed YuMi collaborative robot to carry out tasks like pipetting liquids, carrying equipment, and sorting test tubes.

Agriculture finds value in automation

Farmers have started turning to mobile logistics robots to maintain, measure, and harvest fresh crops. Specialty crops are a prime application for automation, with the need to move heavy carts, narrow rows, and scarce human labor.

Examples of such robots include the Burro from the company of the same name (formerly Augean Robotics) and Carry from Future Acres.

In addition, XAG's unmanned ground vehicle (UGV) works with its drones for precision agriculture. Last year, Iron Ox launched the Grover AMR for hydroponic farming.

Mobile logistics robot uses to keep growing

Mobile logistics robots can be used in environments that are dangerous to humans, such as nuclear remediation with high levels of radiation. RE2 Robotics has developed robots for these applications, as well as defense and other usage.

Honda's Autonomous Work Vehicle has been tested in solar construction sites. Note that most outdoor systems are not as mature or fully autonomous as their supply chain cousins.

YouiBot has developed its mobile manipulators and software for manufacturing facilities.

The global market for mobile logistics robots was worth $2.4 billion in 2017 and could reach $11.2 billion by 2025, registering a compound annual growth rate (CAGR) of 21.2% for that period, according to Allied Market Research.

The COVID-19 pandemic has aggravated worker shortages and added demand for social distancing and contactless retail. The ability of one mobile robot to perform a wide range of tasks at different locations has also boosted the demand for automation.

In response, robotics suppliers are focusing on improving capabilities, managing costs, and offering fleet management software and services. Based on the number of applications that already exist for mobile logistics robots, the market will continue its growth.

About the author

Suchita Gupta is an explorer, musician, and content writer. While pursuing an MBA, she found that nothing satisfies her more than writing on miscellaneous domains. Gupta can be found on LinkedIn and Instagram.

Article topics

Email Sign Up