DETROIT—Skilled welders are hard to find, so it’s best to assign them to higher-return jobs instead of using them for simpler welding tasks, according to Acieta. The company said at Automate 2022 here that fabricators and job shops can now give the easier, low-value weld jobs to its new FastARC CX1000 collaborative robot.

“The FastARC CX1000 repeatedly welds accurate and high-quality welds all day, every day,” said Bill Brauer, senior robotic systems engineer at Acieta. “That means less scrap, increased uptime, and greater capacity, so shops can take on more work.”

Acieta, which exhibited at Booth 1807 at Automate, said it has been a robotics industry leader for nearly 40 years. It provides a range of systems and services for the manufacturing industry.

With locations in Waukesha, Wis., and Council Bluffs, Iowa, the company has integrated more than 5,500 automation systems for customers across the U.S., Mexico, and Canada.

The company added that it is committed to solving challenges facing all manufacturers, such as the need to cut costs, increase productivity and address labor shortfalls. Acieta is a leading FANUC-authorized systems integrator and a member of the RIA Certified Integrator group.

Acieta makes FastARC mobile

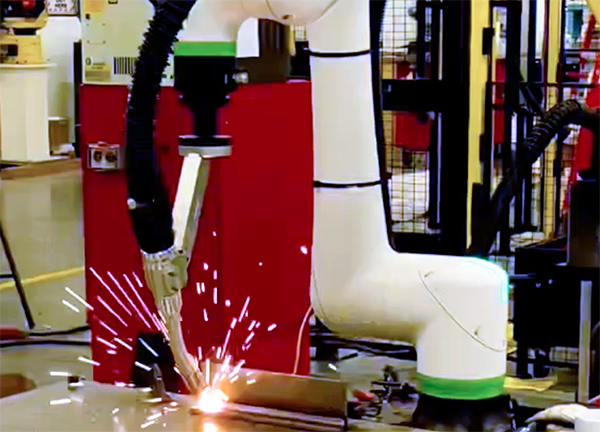

The FastARC CX1000 is a cart-mounted collaborative robot arm that can be moved around the shop wherever it’s needed. Changeover is quick, making the FastARC CX1000 perfect for low-volume, high-mix shops, claimed Acieta.

Hand-guiding the robot makes for simple programming, so no advanced programming experience is necessary, the company said. Its interface is designed to be intuitive, featuring drag-and-drop programming.

As a standard, pre-engineered system, the FastARC CX1000 can be available for delivery and installation within just weeks, according to Acieta. With many end-of-arm tooling (EOAT) options, the CX1000 can be uncoupled from the weld cart and repurposed for different applications such as machine tending or sanding when not welding.

The FastARC CX1000 cobot is equipped with a FANUC six-axis, 10-kg (22 lb.)-capacity cobot arm that Acieta said is maintenance-free for up to eight years. The system is compatible with Lincoln Electric and Miller Electric welders and is IP 67-rated with sealed components to work in industrial environments.

Article topics

Email Sign Up