Additive manufacturing and robotic material removal systems are coming together. Optomec Inc. and Acme Manufacturing yesterday said they have partnered to produce an automated workcell initially optimized for repairing aviation compressor blades made of titanium. The companies have collaborated for two years with input from commercial maintenance, repair, and overhaul, or MRO, and U.S. Department of Defense repair centers for aircraft engines.

“Our collaboration with Acme Manufacturing has brought together complementary technologies that provide a compelling business case for customers,” stated Mike Dean, vice president of marketing at Optomec. “Demanding repair requirements, driven by commercial and DoD repair centers, has led Optomec to enhance our DED [Directed Energy Deposition] capabilities to enable high-volume, high-yield repair for compressor blades, an especially challenging objective for titanium parts.”

Albuquerque, N.M.-based Optomec is a privately held supplier of additive manufacturing systems. The company said the aerospace industry uses the Optomec LENS and Huffman-brand 3D printers for metal component production and repair, as well as to reduce product cost and improve performance. Optomec has delivered more than 500 proprietary additive manufacturing systems to more than 200 customers around the world.

Automated workcell designed to be faster than traditional CNC

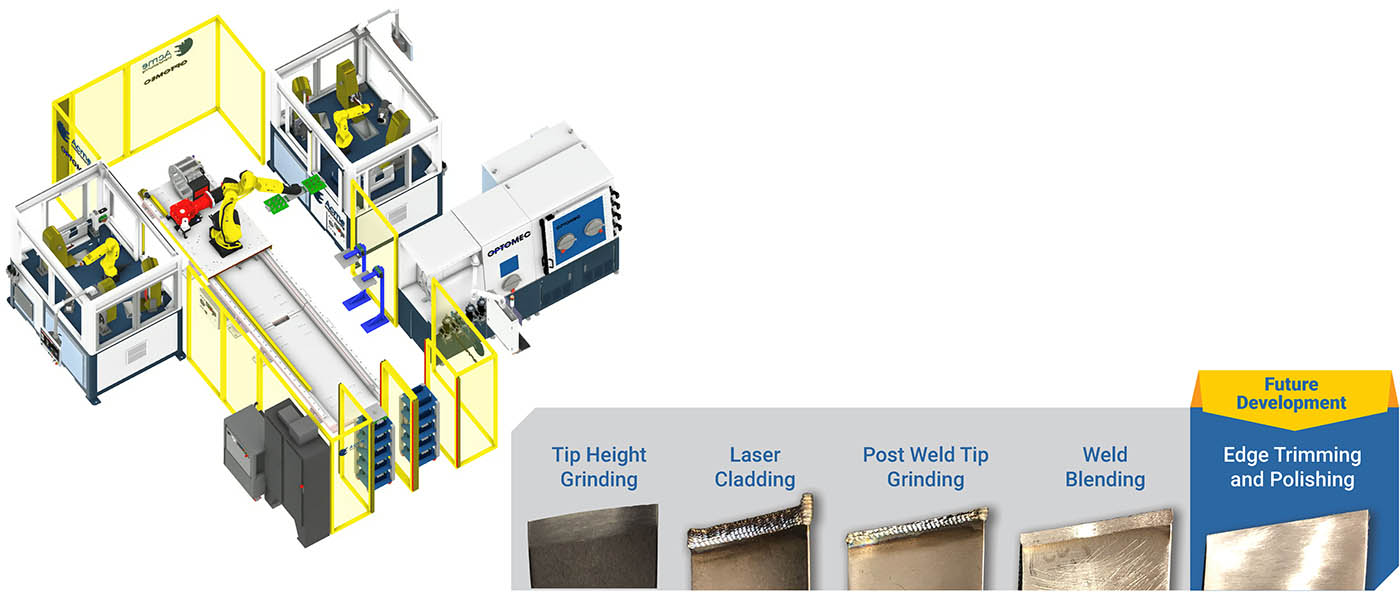

The automated workcell has a repair capacity of 85,000 titanium compressor blades per year. Optomec and Acme Manufacturing said it “provides a compelling ROI [return on investment] when compared to traditional CNC machines and manual TIG welding.”

The workcell uses commercially available technologies that have been certified by civil aviation authorities around the world, said the companies. The entry-level workcell consists of three stations that enable robotic blade tip grinding, 3D additive laser cladding, and robotic post-clad finishing.

The cell also includes an automated pallet load/unload station, a pallet-flipping station, and a robotic material handling system. Each machine in the workcell is capable of automatically adjusting tool paths to accommodate blade-to-blade variations resulting from normal wear and distortion during service.

Optomec said its CS-250 five-axis laser cladding machine can produce high-quality, high-yield precision welds for titanium compressor blades using proprietary LENS DED and AutoCLAD advanced vision and adaptive tool-pathing technology in a controlled argon atmosphere.

The Acme Manufacturing MRO blade-tip repair machines can be configured for blade tip grinding, weld blending, and polishing. The partners said the system is equipped with “first of its kind” auto path generation, which allows for a high-mix, low-volume production environment. This new technology is three to four times faster than traditional CNC machines, they claimed.

Optomec, Acme Manufacturing serve MRO centers

Working in tandem, the systems in the workcell provide a productive, real-world implementation of Industry 4.0 and digital thread concepts, said Acme Manufacturing and Optomec.

“Acme has delivered over 200 robotic material removal systems to the aerospace industry in the past 35 years, largely for new part manufacturing,” said G.A. “Fritz” Carlson III, president and CEO of Acme Manufacturing.

“By utilizing efficient and repeatable robotic finishing technology, we can enable MRO engine repair centers to improve overall component quality and help lower unit costs,” he added. “I am excited about our teams’ developments in auto path generation, which allows us to enter a new market of automated material removal systems.”

Auburn Hills, Mich.-based Acme Manufacturing said it is one the earliest pioneers in material removal automation. Since 1910, the company has remained family owned and operated by four generations of the Carlson family.

Acme said it engineers cost-effective material removal and process systems to meet complex finishing requirements. The company noted that it has produced over 3,700 robotic systems. In addition, Acme offers a full line of coated abrasive belt centerless grinding systems, ideal for O.D. (outside diameter) grinding of bar and tube materials.

Optomec plans be exhibit at stand No. 12.0 E129 at Formnext in Frankfurt, Germany, from Nov. 15 to 18.

Article topics

Email Sign Up