Developers are taking more steps toward “lights-out” warehouses that operate autonomously 24/7. Konoike Transport Co. and OSARO Inc. today said they collaborating on a new project at the Konoike Institute of Technology Innovation Center, or KITIC. They said it will showcase Japan’s first prototype of warehouse operations where mobile robots will work with picking robots optimized for e-commerce applications that involve large SKU inventories.

“We are honored to be the first in Japan to conduct a demonstration prototype of an OSARO picking solution with an AMR [autonomous mobile robot],” stated Tadatsugu Konoike, director and senior managing executive officer at Konoike Transport. “We decided to work with OSARO because we believe that OSARO is superior for use in the rapidly changing logistics field in terms of automatic machine learning, data collection, and accurate picking.”

Osaka, Japan-based Konoike Group said it has innovated solutions to problems beyond logistics and is expanding into manufacturing, medical, airport operations, and more.

OSARO, Konoike, and inVia address labor shortages

Robotics and artificial intelligence can automate traditionally manual tasks, addressing the global challenges of increasing logistics volumes and labor shortages aggravated by the COVID-19 pandemic, said Konoike and OSARO.

“Japan is facing a shortage of labor due to the declining birthrate and aging population, but we hope to turn this challenge into an opportunity and develop a new form of workplace at KITIC and introduce it to the world,” said Tadatsugu Konoike.

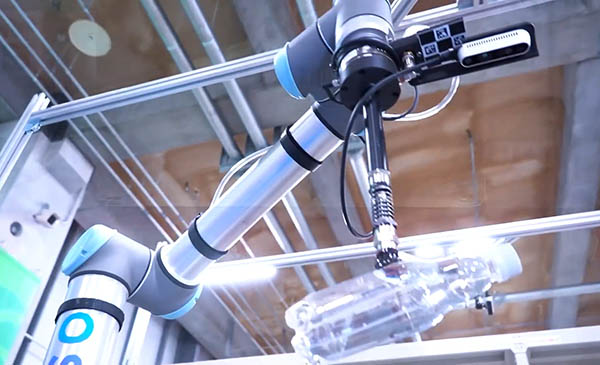

The pilot will link piece-picking robots from OSARO with AMRs from inVia Robotics Inc. to provide a smooth path from warehouse inventory to packing and shipping operations, said the companies.

“The system we created is an example of a modular, flexible, and brownfield-compatible fulfillment system,” said Derik Pridmore, CEO of OSARO. “Future warehouses will leverage systems like this to scale up for increasing demand from customers without requiring hiring additional manual labor.”

OSARO designs and deploys materials handling automation using software-defined robotics with advanced machine learning for object recognition and control software. The San Francisco-based company said it has optimized its piece-picking solutions for e-commerce markets, where challenges include high SKU inventories, complex packaging, and fragile items requiring delicate handling.

Westlake Village, Calif.-based inVia Robotics said its AMRs and AI can help businesses fulfill online orders more efficiently. The company claimed that its systems, provided through a robotics-as-a-service (RaaS) model, can increase productivity and accuracy and minimize reliance on labor at a fraction of the cost of traditional automation.

Partners smoothe path to shipping

In the KITIC project, OSARO and InVia's technology takes the following steps:

- The AMR locates the shelf in the warehouse where the required items are stored.

- It then retrieves the correct inventory storage bin and carries it to the pick-and-place robot station.

- The picking robot picks the item from the inventory storage bin and places it in a different bin, ready for shipment.

OSARO said its AI vision system enables the robot to perform advanced pick-and-place operations by recognizing transparent, deformed, reflective, and irregularly shaped items—even if they are randomly arranged in the inventory storage bins.

The prototype will prove that tasks such as inventory movement and picking items for order fulfillment can be fully automated, according to the partners. Through the pilot, OSARO and Konoike hope to identify interoperability problems that may arise when multiple types of robots interact and to resolve thesm ahead of operational deployment.

Article topics

Email Sign Up