Growing adoption of mobile robots has led to efforts to get fleets from multiple vendors to work together. OTTO Motors yesterday said that it is one of the first autonomous mobile robot, or AMR, vendors to support the VDA 5050 interoperability standard and to open-source its connector.

“Interoperability, particularly compliance with standards like VDA 5050, will play a crucial role in facilitating the adoption of automation by manufacturers worldwide,” stated the Kitchener, Ontario-based company. “As the industrial automation industry evolves, OTTO Motors is dedicated to supporting and enhancing interoperability to unlock new possibilities for autonomous material handling.”

OTTO Motors said its AMRs have accumulated more than 4 million hours of driving experience, automating materials handling in factories and warehouses. The company was recently recognized as a top 10 global robotics provider, named to Fast Company’s 2023 list of “Most Innovative Companies. Seventy percent of OTTO’s customers are Fortune 500 companies such as GE and Toyota.

VDA 5050 offers benefits to mobile robot users

VDA 5050 is an interoperability standard created to establish a common interface among multiple automated guided vehicle (AGV) and AMR providers. Initially developed for German automakers, it outlines specific requirements and guidelines related to safety, performance and communication for AGVs and AMRs.

The standard provides many benefits to manufacturers looking to introduce automation, including reduced costs and downtime, as well as improved safety and flexibility, said OTTO Motors. However, these benefits cannot be fully realized until all mobile robot vendors ensure that their systems are VDA 5050-compliant, noted the company.

“Supporting VDA 5050 is a significant milestone for OTTO Motors,” said Jay Judkowitz, vice president of product at OTTO Motors. “By adhering to this standard, we're empowering global manufacturers with more sophisticated and cohesive automation solutions to tackle their toughest operational hurdles. As the automation landscape evolves, it's vital for all AGV and AMR vendors to follow suit.”

OTTO Motors collaborates on interoperability

Along with InOrbit and Ekumen, OTTO Motors claimed that it has made further strides toward interoperability by being the first vendor to make its VDA 5050 connector open-source. OTTO said it enables any ROS-based AMR to be controlled by a VDA5050 Central Control—including competitors’ systems if they adopt the standard.

This also ensures quick compatibility and accelerates global support for the standard, said the company, whose open-source code can be accessed on GitHub.

OTTO Motors added that it has conducted rigorous tests to verify the functionality of VDA 5050 support in its AMRs. These tests proved that VDA 5050 compatibility can enable seamless communication and integration between AMRs and third-party controllers, it said.

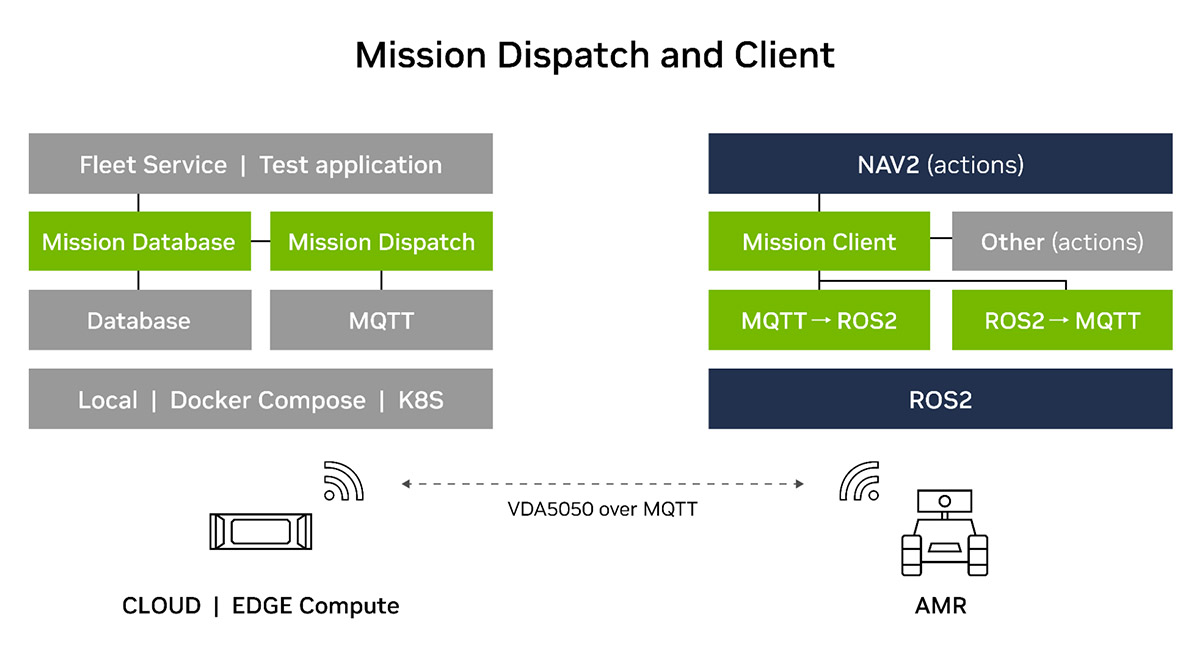

One of these tests was conducted by industry leader NVIDIA, which confirmed in simulation that its Mission Dispatch software worked seamlessly out of the box with the OTTO Motors VDA 5050 connector.

“Managing and testing fleets of autonomous robots requires two computers—one in the robot and one in the cloud—to dispatch tasks and communicate the status of these tasks to and from the robots,” said Gerard Andrews, product marketing manager for robotics at NVIDIA.

“As part of the NVIDIA Isaac robotics platform, we built Mission Dispatch and Mission Client on VDA 5050 to facilitate interoperability for users handling heterogeneous robotics fleets,” he said. “OTTO Motors embracing VDA 5050 will help to further advance interoperability.”

InOrbit demonstrated VDA 5050 compatibility

In October 2022, OTTO Motors’ commitment to VDA 5050 compatibility was further demonstrated with InOrbit's robotics operations (RobOps) platform. In this demonstration, OTTO 100 and an AGV were seamlessly controlled by InOrbit’s master control, unlocking new levels of flexibility for material handling operations.

In the video below, InOrbit’s master control was able to directly issue an order to OTTO 100, and when it detected that the two robots were positioned too closely together, disrupting traffic flow, the master control paused the AMR and allowed the less capable AGV to proceed.

“InOrbit and OTTO Motors are aligned in our commitment to accelerating the adoption of robotics through effective robot orchestration,” said Florian Pestoni, co-founder and CEO of InOrbit. “We believe that the ability to manage material handling across multiple vendors is critical for the industry to thrive.”

“Our collaboration with OTTO Motors is a crucial step towards achieving this goal,” he stated. “We are excited about the impact this will have on the industry and look forward to continuing our partnership.”

OTTO Motors AMRs execute a variety of tasks

OTTO Motors said its spring 2023 software release has enabled its AMRs to execute a variety of tasks under a VDA 5050-compliant central controller:

- Navigate to a specified point: OTTO AMRs can be commanded to navigate to a simple coordinate, a predefined waypoint, a configured docking endpoint, or a configured charger.

- Pause and resume motions: The VDA5050 standard allows for a simple pause and resume command to be sent to any robot within its control. This is helpful when considering and designing intersections.

- Powered endpoints: Once an OTTO AMR arrives at a docking endpoint, it can be commanded to transfer its payload with either an OTTO-standard conveyor or lift.

- Work in place: OTTO AMRs will not accept any other commands until the work in place has been ended, which it said ensures a safer and more predictable interaction between humans and robots where a manual load or unload is required.

More about the VDA 5050 standard, including discussions about its importance for manufacturers and the considerations for adoption, is available at https://ottomotors.com/vda5050.

Article topics

Email Sign Up