Montreal is a North American fashion capital. For more than a century, the Garment District established the city as a hub of innovation in design, manufacturing, and handling of textiles. Planiform was founded in the 1970s to deliver systems for demanding garment manufacturing and dry-cleaning applications.

Just as styles have changed over the past 50 years, Planiform’s conveyance and garment-on-hangar (GOH) systems have continued to evolve. The company has increased automation capabilities to meet new requirements for industrial laundry services and distribution centers.

Planiform’s latest innovation, the GOH Hive, enables fashion retailers to boost e-commerce efficiencies, according to Charlotte Girod, director of sales. In the past, these companies would have one distribution center (DC) for store replenishment and another for e-commerce.

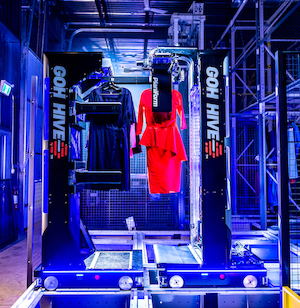

Now, it is combining those facilities—and their inventories—to support omnichannel retail solutions. GOH Hive is an automated storage and retrieval system (ASRS) for hanging apparel with smart robots for picking, helping operations overcome labor market challenges and seasonal scalability.

“Because of the lack of systems to capably automate garment-on-hanger storage on the market, we designed GOH Hive to help distribution centers meet today’s demands,” Girod said. “Most DCs are still working with traditional, one-level racking systems while trying to handle millions of garments.”

“The ideal user is likely processing 100,000 to 150,000 units per day over three shifts,” he added. “In these environments, automating the process uses space more efficiently and requires less labor.”

Planiform ASRS enables efficiency

Traditionally, workers would have to hunt through large warehouses or move entire trolleys to the pick station to induct garments into inventory and go through the process again to retrieve garment for order fulfillment. This can be particularly cumbersome for fashion resale or rental operations, where every item has a different SKU.

With Planiform’s ASRS, an on-premises server communicates between the warehouse execution system (WES) and the robots via Wi-Fi, according to the head of Planiform's automation department.

The GOH Hive uses two types of robots: one to navigate through the racking, and a second that receives up to 30 hangers before moving to the operator workstation. The pick stations can work with a pouch sorter or other system for the intermediary steps.

GOH Hive successfully increases throughput

The Planiform engineers worked closely with the local Beckhoff Canada team, including Regional Sales Manager Ted Sarazin and Application Specialist Yan Letourneau. From an engineering perspective, the GOH Hive required flexible controls and networking technologies.

Beckhoff said its control hardware, TwinCAT automation software, and the EtherCAT industrial Ethernet system helped Planiform optimize the equipment. The hardware also needed to be extremely compact to fit the required functionality into small enclosures on the robots.

“We have built an incredibly efficient system that is 10 times faster than traditional methods,” said Girod. “An operator walking aisles and manually picking garments can typically handle 100 units per hour on a traditional system.”

“With assistance from the robotic capabilities of GOH Hive, that operator can manage about 1,000 units per hour,” he noted.

Not only can this automation help DCs increase throughput, but they can also scale to accommodate higher demand during peak seasons. Planiform’s first installation was for a major fashion retailer with both an e-commerce channel and a brick-and-mortar presence.

A complete suite of new automation technology from Beckhoff assisted in this success. Faster communication and greater functionality in a smaller footprint were just starting points in terms of the advantages, said the companies.

Based on the success of GOH Hive, Planiform said it plans to adopt more Beckhoff systems. It said it will also upgrade its existing automated carousels using Beckhoff technology to reduce cabling effort and minimize control cabinet requirements.

Fashions change and technologies advance, but as the working relationship between the Planiform and Beckhoff teams demonstrated, great collaboration never goes out of style, said the companies.

Beyond technology, Beckhoff provided experts who offered timely assistance, according to the head of Planiform's automation department: “The engineering support we received from Ted and Yan was incredibly helpful. Beckhoff visited our facilities to help us with development and troubleshooting as needed, so that really gave us the upper hand.”

About the author

Chris Bladek, is marketing manager at Beckhoff Automation Ltd.

Article topics

Email Sign Up