This month, the Supply Chain Group editorial team offers Logistics Management readers a preview of the latest warehouse and distribution center management equipment, automation and software products that will be introduced on this year’s trade show floor.

Run two voice-directed picking solutions together

The Lydia Voice Co-Exist Solution is targeted to Vocollect Voice customers who want to add Lydia Voice alongside their existing deployment. The solution enables companies to easily operate a two-vendor voice strategy without having to undertake any additional voice integration efforts. Operational in a very short time with minimal customer resources, the solution delivers 11% productivity improvement.

Booth: S4170

Fully automated goods-to-robot order picking for e-commerce

Combining robotic vision, artificial intelligence and gripping with automated storage and retrieval system shuttle technology, vertical lifts and conveyor, the order picking process can be completely automated. The fully integrated system is ideal for e-commerce fulfillment operations in a challenging labor market and handling high volumes of smaller-size orders. It uses unique gripping technology to pick individual items of a range of sizes, shapes, fragility and weights. When paired with AI, the gripper enables the automation of highly unstructured tasks found in e-commerce distribution. Little to no human intervention is required for the system to provide consistent accuracy and high throughput to meet customer demands.

Booth: S618

New shuttle, warehouse control system

Flexible, scalable and fast, the new OSR Shuttle Evo+ maximizes space utilization and energy savings by merging and managing reserve storage and forward picking as a single dynamic ecosystem. Functionally, it combines a high-performance shuttle system with the agility of an autonomous, flexible path transport system—centrally storing goods, raw materials, overstock and buffered orders in a high-density space. Upon retrieval, items are sequenced and quickly delivered where and when needed with a fleet of Open Shuttle automated mobile robots. Also on display, redPILOT software acts as a control tower to plan and optimize warehouse and distribution systems in real time by managing Big Data, predictive modeling, analytics, Internet of Things systems and artificial intelligence to maximize performance and return on investment.

Booth: S1231

Autonomous order fulfillment solution picks, process, consolidates orders

The goods-to-person Butler artificial intelligence-enabled autonomous robot optimizes the supply chain process from inventory storage and replenishment to order picking. It works seamlessly with the Butler PickPal autonomous order fulfillment solution to pick, process, consolidate and prepare orders. It works collaboratively with a human operator to fill orders, increasing picking productivity from the same workstation.

Booth: S3275

Collaborative mobile robot enhanced with greater capacity, more configurations

Recently updated to support up to a 160-pound payload, the Chuck+ collaborative robotic pick cart triples the productivity of warehouse workers. It leads pickers through their zones to help them stay on task and work more efficiently. Using artificial intelligence to prioritize work, reduce walking and speed up tasks, the unit can be configured in a variety of arrangements. This allows it to carry 16 average e-commerce orders, or to support garment on hanger, shoes, kitting, piece picking and other fulfillment needs.

Booth: S3983

Scalable solutions for e-commerce and fashion markets

Two new automated handling systems help warehouses and distribution centers manage the frequently changing dynamics found in the e-commerce and fashion markets. The Airpick combines efficient picking with error-free automated sortation to individual orders in the Airtrax pocket sorter. It sorts a range of products and requires minimal investment. Using Adapto shuttles for product storage and retrieval, the Fastpick goods-to-person order fulfillment system handles short-term peaks in a cost-efficient manner. Both solutions can be scaled up as required, facilitate the efficient handling of returns, provide high throughput rates and shorter lead times, and are engineered to improve the user experience.

Booth: S1203

Cart equipped with on-board power

Built with a choice of 30- or 48-inch tabletop, the PC Series Mobile Powered Cart has on-board power to run a computer, LCD, industrial thermal printer and laser printer simultaneously. Its work surface provides space for equipment, inventory, paperwork and other items, while the entire unit is easily relocated with minimal force, thanks to new, specialized casters. All models have a maximum load capacity of 500 pounds and can be outfitted with lightweight swappable lithium or sealed lead acid battery, additional middle shelf, slide-out printer tray, keyboard and mouse tray, LCD holder, scanner holder and more.

Booth: S4168

WES enhanced with fault recovery visualization function

The Savanna.NET warehouse execution system and a layer picking solution is a complete, turnkey automation solution, including a high-density automated storage and retrieval system. New in the WES—which integrates both a warehouse management system and warehouse control system—is FireFly fault recovery visualization. The WMS is flexible and modular, allowing it to support stand-alone conventional and automated warehouses and configurable to enhance a company’s business processes. In addition to optimizing, managing and controlling any storage facility for time and cost savings, the WMS helps position an operation for future growth.

Booth: S1247

Mobile printer’s platform connects to apps for versatility

The PW2NX 2-inch mobile printer features robust connectivity options and supports the supplier’s application-enabled, printing enterprise label printing platform that connects to smart apps for accessibility and expandability. To prevent downtime, the printer leverages a Cloud-based Internet of Things maintenance service to identify issues before they become critical. It can be used outdoors and inside, making it ideal for distribution centers and field deliveries. Features include a polycarbonate body for high shock resistance and impact absorption when dropped, and a high-quality elastomer on its edges to absorb impacts and provide rugged durability to protect the printer against drops. For easy operation, it incorporates an intuitive key design and universal icons.

Booth: S5256

Reach, place pallet loads at heights up to 542 inches

Lifting 4,500-pound palletloads to a height of 542 inches, the new high-capacity Reach-Fork truck optimizes storage space in tall buildings by accommodating up to 10 levels of rack. It is ideal for cold storage and freezer applications. Offering integrated telematics capabilities to increase efficiency, the vehicle also offers universal stance and an open-view mast for better visibility and ergonomics. For longer battery shift life, the vehicle is outfitted with an optimized displacement pump for more efficient motor operation. Operators are assured of proper fork and pallet placement with the Vantage Point camera and its high dynamic range image sensor that provides simultaneous low- and high-light performance.

Booth: S2003

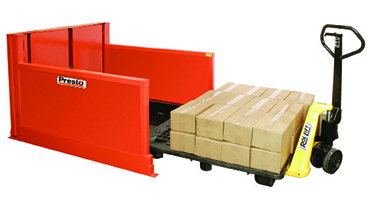

Reduce fatigue in manual pallet loading, unloading with leveler

The P4 Floor Height Load Leveler improves worker productivity and reduces fatigue in manual pallet loading and unloading operations. It includes a pan-style platform that lowers to floor height so pallets can be placed and removed with hand pallet truck. In loading operations, a pallet is placed on the platform, which is then raised by hydraulic power to its full height position. As goods are loaded onto the pallet, the operator lowers the platform so each succeeding tier of goods can be loaded at the same height. Accessible from all sides, the units come in capacities up to 4,000 pounds, platform sizes of 44 x 48 inches or 52 x 48 inches and are equipped with a photoelectric toe guard to stop downward travel if the beam is interrupted.

Booth: S2431

End rider pallet truck’s features boost productivity, operator comfort

The new MPE060-080VH end rider pallet truck is outfitted a range of ergonomic, productivity enhancing and maintenance-friendly features. To keep operators comfortable throughout their shift, the vehicle can be outfitted with an optional extended platform that provides over 30% more usable foot space and the Ultra Cushion that reduces shock and vibration. The push-button Precision Pick function enables precise bi-directional control of speed and coasting, allowing operators to easily navigate between pick locations. Engineered with extended service intervals of up to 1,000 hours, the maintenance-friendly vehicle offers quick, secure access to key components, enabling tasks to be completed in reduced time. Further, LED platform and fork lights increase operator awareness in low light or congested areas, like dim storage aisles and dark trailers; they also raise visibility and minimize costs due to product and equipment damage.

Booth: S3603

Article topics

Email Sign Up