As with other industries, the COVID-19 pandemic has accelerated demand for automation in the restaurant industry. However, small and midsize businesses, or SMBs, have tight profit margins and are understandably reluctant to invest in new, complex technologies even as they struggle with turnover and labor shortages, according to Haitham Al-Beik, CEO of Wings.

Littleton, Mass.-based Letsbutterfly Inc., which does business as Wings, is developing proprietary systems in its HiveRobotics Lab for “autonomous sustainable retail” (ASR). Al-Beik has spoken with several restaurant franchises about the challenges they face and what they want from robotics suppliers. He shared his findings with Robotics 24/7:

What are some of the biggest challenges facing small and midsize food-service businesses?

Al-Beik: Across the board, the challenges stem from logistics highly dependent on human labor. Even at capacity, the output is limited — human workers can't compete with 80 digital orders coming through in a single hour. As a result, customers have less of a burden when making an order, but they take it on when they wait to pick up their orders.

Today, with the labor shortage alone, the logistics are overwhelmed, and the customer experience inevitably plummets. Therefore, the biggest challenge is upgrading logistics to support a much more streamlined input and output retail system while retaining the same quality of service.

It's not about replacing labor with robotics but addressing the whole operation and business model. Retailers need to start thinking about their business as a single system or robot, rather than a box with independent and heterogenous robots within it.

How has the COVID-19 pandemic made pain points more acute or created new ones?

Al-Beik: The pandemic exposed many existing vulnerabilities of the services economy. In addition, it is now more apparent that the retailer has no control over the external logistics—human customers— due to safety and security regulations.

The environmental changes forced retailers' hands to work on increasing customer satisfaction while retaining staffers who continue to be overworked.

The pandemic showed that human labor had already approached peak performance. We will have to automate operations while bringing about more creative work opportunities to break that barrier. The industry needs to transition to an economy where more entrepreneurs and innovations are locally driven.

What are some examples of automation intended to help with internal and external logistics? For example, are we talking about food-preparation robots, server robots, or automated storage and retrieval systems (ASRS)?

Al-Beik: Before we jump into particular automation solutions and pick those with the most impact, we need to understand and plan out an autonomous strategy to be implemented for years to come. Transitioning to a standardized adoption of automation takes time.

For example, the transition to digital orders has only been recent. In contrast, over 40% of restaurants do not have up-to-date websites. The path towards autonomous retail is taken by addressing three aspects of a labor-driven logistics framework: human work, workflow, and human-to-human communication.

Many retailers embarked on automation starting with digital orders that address the cashier and delivery stations and the workflow that connects them. This eliminated the need for staff to write down or input orders.

It also eliminated the human workflow of taking orders from the customer and sending it over to the assembly station. In addition, human communication has been eliminated, since all communication is digitized to modify and adjust orders on demand.

Transitioning to digital orders and communication was a significant first step. It enables the end customer to be more versatile in interacting with the retailer. The next step is to continue automating the rest of the internal logistics by moving backward, carrying the “end-in-mind” benefits.

The challenge is deciding whether to automate a station, a workflow between stations, or both.

For example, an automated assembly station fulfilling orders at two or four times the speed of a human being will find itself bottlenecked when attempting to transport said orders to a delivery station. Even if the delivery station is automated, it cannot benefit from the assembly stations' speed because the highway becomes the limiting factor.

What can be done about these workflow bottlenecks?

Al-Beik: The overarching guidance is to upgrade workflows to handle the accelerated transfer of work between stations, then upgrade its connected stations accordingly.

While food preparation can be seen as the first step to automate, it does not address how the food prepared will be delivered to customers in a timely fashion and at their intended destination: dine-in, pick-up, or drive-through. Instead, automating workflow between the assembly and the delivery station as a whole would provide the most impact.

Today, a delivery station is an analog shelving unit, atop or behind the counter. It does not address the workflow portion, as a human still manages it. How often have we been experienced an order that's ready to pick up but is not yet on the shelf?

In this scenario, automated storage of orders ready to be picked up and a customer retrieval system would reduce the need for a human to manage the workflow between the assembly and delivery stations. The challenge is to develop such a system that can do the following:

- Increase customer versatility, regardless of space

- Take minimal valuable customer footprint

- Eliminate the need for assemblers to leave their stations

- Reduce work for the assembler and customer

Why aren't these sufficient—is it technological limitations, or a lack of understanding of the use cases?

Al-Beik: The tendency to automate stations first is a knee-jerk reaction to eliminate labor without understanding the use cases. The most friction for retailers is where internal and external logistics connect. A retailer can set up and tune its internal logistics however it wants.

However, external fulfillment is dynamic and time-sensitive. It is challenging to predict, especially considering each customer's unique preferences regarding what, when, and where they want their orders — even without considering their allergies, sensitivities, or accessibility requirements.

Technologies coming to the market need to understand the logistics and customer needs fully — the more it can support a versatile customer experience, the more sustainable it is.

What do restaurant operators and franchisees want or need?

Al-Beik: The short-term needs are to reduce costs and reliance on labor and retain their I/O bandwidth. A model that can fulfill such a need would allow franchisees to scale their businesses and replicate them across many locations.

The long-term need is to offer customers a versatile experience with a more sustainable model than in traditional retail. Moreover, the automation must be modular, scalable, and take as little space as possible. Such systems would allow franchisees to quickly deploy their products at urban and non-urban locations.

Retail will transition from a management operation to a more administrative operation. At the same time, robotics will minimize people focusing on logistics, so they can do more customer-facing, value-add work.

What types of solutions are better focused on these requirements?

Al-Beik: The next step is to elevate the ordering technologies while addressing the assembly-to-delivery workflow and stations. It's imperative that the solution increases revenue by taking back considerable time that has been wasted from layers of friction.

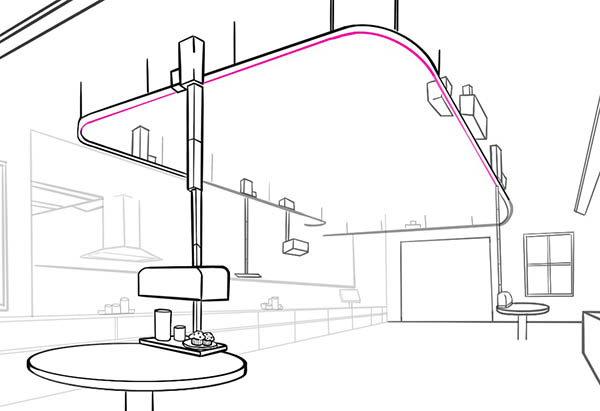

Wings' systems address this workflow by retaining the customer and kitchen footprint as much as possible while reducing stress on the staff and elevating the customer experience.

What are the differences in designing for so-called ghost kitchens versus regular restaurants?

Al-Beik: The dark or ghost kitchens separated logistics concerns to address changes in customer behavior and how they want their products. In a more urban setting, customers expect more on-the-go, pickup or delivery by third parties — where dark kitchens excel. Similarly, restaurants will have to do the same by restructuring the kitchen-to-customer delivery systems with a single input channel.

By standardizing and streamlining the input, the mechanisms can now focus on delivery. For example, a drive-through becomes a drive-pickup when only a single input channel is implemented for digital orders. In this case, a restaurant without a dine-in will behave similarly to a dark kitchen.

How quickly are the market and technologies serving it evolving? When can we expect widespread deployments?

Al-Beik: As mentioned earlier, this transition will take time, since cutting-edge technologies will require numerous people to test it day in, day out in the real world. Initially, major brands will drive and adopt such technologies first before SMBs can afford them.

Widespread adoption of automated workflows and customer-facing systems will begin after a year of “being in the wild,” as people become more comfortable with it.

Soon after, stations will be automated, offering concurrent operations for a more seamless and streamlined path to augmentation and higher-bandwidth retailers.

While we've talked about SMBs, how much are the big chains pushing advances in food-service automation?

Al-Beik: The big chains will most likely drive the adoption of food automation, as they have the exact same needs as SMBs but on a larger scale. In retrospect, SMBs with the right automation should have the option and ability to scale such a system in a modular way to a big chain as they grow.

Big chains are looking at the immediate short-term impact to reduce cost and labor while retaining the same input and output while considering long-term benefits from an ROI [return on investment] and sustainability.

In addition, many chains are looking into their external delivery services with unmanned ground vehicles (UGVs) and unmanned aerial vehicles (UAVs).

What can restaurateurs expect in the coming year?

Al-Beik: Restaurateurs will see an adoption of next-generation robotics that does not occupy the same space as humans to give customers and staff members more versatility.

Moreover, retailers will focus on a single digital communication channel through their smartphones to best facilitate their customer needs, allowing in-the-moment and just-in-time operations. In this case, the restaurant becomes a pickup station or a dine-in experience where the same type of robotics system is doing the delivery.

We will also see the idea of a waiter or server transitioning to a customers' pocket with display and voice AI solutions. Nonetheless, the restaurant will have a concierge on staff who run operations and be its face to customers. The future will bring more freedom for customers and retailers to be more versatile and scalable.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up