DETROIT—As companies increasingly rely on collaborative robots to support factory-level tasks and compensate for labor shortages, Schaeffler is exhibiting its growing lineup of high-precision planetary gearboxes and strain-wave gear sets at Automate 2023 this week.

“For several decades, Schaeffler has provided a comprehensive range of solutions for industrial robotics based on conventional bearing components and specialized products,” said Ulrich (Uli) Mayr, vice president of industrial automation for Schaeffler in the Americas, in a release.

“With our recent acquisition of Melior Motion and the development of our strain wave gearbox with its integrated torque measuring system, Schaeffler is now further expanding its offerings for the robotics sector,” he added. “This is an exciting time to be at Automate, and we are proud to showcase our technological expertise and systems know-how through our ever-increasing portfolio of automation solutions.”

For more than 75 years, Schaeffler Group said it has been a leading developer in motion and mobility, supplying the automotive and industrial sectors. The company manufactures high-precision components and systems for powertrain and chassis applications, as well as rolling and plain bearing systems for numerous industrial applications.

New gearing for cobots and other automation

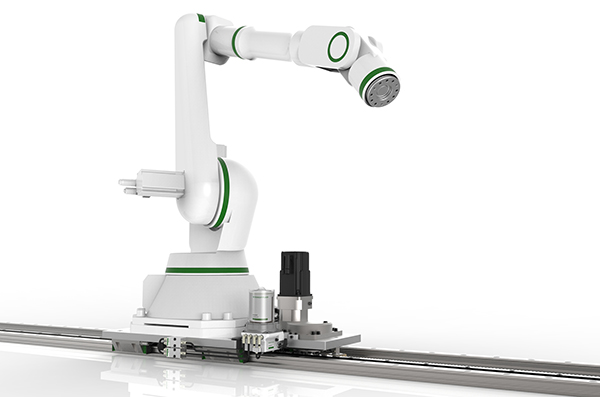

Schaeffler is showing its innovations for industrial automation and robotics at Automate under the theme “Driving Smart Manufacturing at Every Axis.” In addition to its portfolio of linear and rolling bearings, the company said it is a trusted partner for system components, precision gearboxes, pivot bearing supports, drive motors, and sensors, as well as the seventh axis for robotics.

PSC-Series precision planetary gear units

Schaeffler said its new PSC-series planetary gear units provide precision for a wide range of industrial automation and robotics applications. PSC stands for “precise”—the highest precision available on the market, “silent”—the lowest noise level, and “constant”—a constant level of precision during the application period, it said.

Whereas traditional gear drives exhibit torsional backlash that only increases with wear, Schaeffler claimed that its PSC gear units feature a patented tooth system that reduces torsional backlash to less than 0.1 angular minutes – a value that remains constant throughout the device's entire operating life of 20,000 hours.

RT1 and RT2 precision strain wave gear sets

Schaeffler noted that it has been producing strain wave gears for the automotive market for many years. By transferring its engineering and manufacturing technologies to other manufacturing, Schaeffler is now also offering two series of precision strain wave gears for industrial automation and lightweight robotics applications.

Encompassing five sizes, Schaeffler said its standard-duty RT2-series strain wave gears cover approximately 80% of normal collaborative robot applications. Other variants are available in a variety of configurations – including versions with a hollow shaft and for direct mounting on the motor shaft, as a closed unit with seals, and as a component set.

Designed for high-torque applications up to 900 Nm, Schaeffler currently offers its heavy-duty RT1 gear units in four sizes. They are suitable for cobots, thanks to their low weight and compact design, said the company.

“The RT1's backlash-free and wear-resistant gear teeth ensure excellent positional accuracies throughout the unit's entire operating life,” it said.

RT1-T precision strain wave gear with integrated sensor

In the automation field, the ability to measure dynamic forces and torques is key to controlling the quality of machine processes such as tracking a robotic arm, said Schaeffler.

The company said its heavy-duty RT1-T precision strain wave gears feature integrated microelectronics, embedded AI, and its proprietary Sensotect sensory coating, which measures right at the load point with highest sensitivity and accuracy without reducing mechanical stiffness.

XZU-Series angular contact needle roller bearings

RT1- and RT2-series strain wave gears incorporate Schaeffler's proprietary double-row XZU-series angular contact needle roller bearings that deliver up to 30% more tilting rigidity and 20% less friction vs. crossed roller bearings, which are typically used in gear set applications.

See Shaeffler at Automate

Schaeffler is located in Booth 841 in the Huntington Place Convention Center.

Featuring the latest in robotics, vision, artificial intelligence, motion control, and more, Automate is North America's leading robotics showcase, according to the Association for Advancing Automation (A3). The event presents innovations in industrial automation for manufacturing from more than 600 leading exhibitors.

Schaeffler provides products and services for CO₂-efficient drives, electric mobility, Industry 4.0, digitalization, and renewable energies. With more than 1,250 patent applications in 2022, Schaeffler is Germany's fourth-most innovative company, according to the German Patent and Trademark Office (DPMA).

The Schaeffler Group reported sales of approximately €15.8 billion ($17 billion U.S.) in 2022. With around 84,000 employees, Schaeffler said it is one of the world's largest family companies. Herzogenaurach, Germany-based Schaeffler has its U.S. headquarters in Troy, Mich.

Editor's note: For more about Automate 2023, visit Robotics 24/7's special coverage page.

Article topics

Email Sign Up