Artificial intelligence and simulation promise to help industrial automation address new challenges. Siemens AG and NVIDIA Corp. today announced the expansion of their partnership and plans to first connect the Siemens Xcelerator open digital business platform with the NVIDIA Omniverse platform for 3D design and collaboration.

The companies said their collaboration will “enable an industrial metaverse with physics-based digital models from Siemens and real-time AI from NVIDIA in which companies make decisions faster and with increased confidence.”

“Siemens and NVIDIA share a common vision that the industrial metaverse will drive digital transformation,” stated Jensen Huang, founder and CEO of NVIDIA. “This is just the first step in our joint effort to make this vision real for our customers and all parts of the global manufacturing industry.”

“The connection to Siemens Xcelerator will open NVIDIA’s Omniverse and AI ecosystem to a whole new world of industrial automation that is built using Siemens’ mechanical, electrical, software, IoT [Internet of Things], and edge solutions,” he added.

NVIDIA, Siemens connect AI, simulation, and IT

The partnership brings together complementary technologies and ecosystems to realize the industrial metaverse, according to Siemens and NVIDIA. Munich-based Siemens described itself as a leader in industrial automation, infrastructure, and transportation.

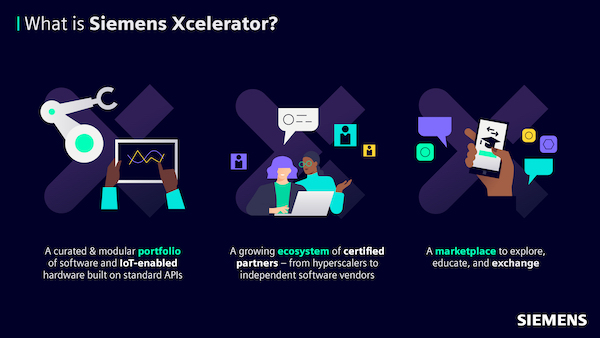

Siemens said its Xcelerator platform connects mechanical, electrical, and software domains across the product and production processes.

“Siemens Xcelerator will make it easier than ever before for companies to navigate digital transformation – faster and at scale,” stated Roland Busch, president and CEO of Siemens AG. “By combining the real and the digital worlds across operational and information technology, we empower customers and partners to boost productivity [and] competitiveness and scale up innovations.”

The company also announced its Building X software-as-a-service (SaaS) offering as part of Siemens Xcelerator. Building X is a new cloud-based, smart building suite to create a single source of truth (SSOT) to take complexity out of digitalization and help customers achieve net-zero goals. It is an end-to-end data and analytics suite bacross domains such as energy management, security, and building maintenance.

Santa Clara, Calif.-based NVIDIA said Omniverse is an AI-enabled and industrial-scale virtual-world engine that enables full-fidelity, live digital twins. NVIDIA AI is used by more than 25,000 companies worldwide and the intelligence engine of Omniverse in the cloud and autonomous systems at the edge.

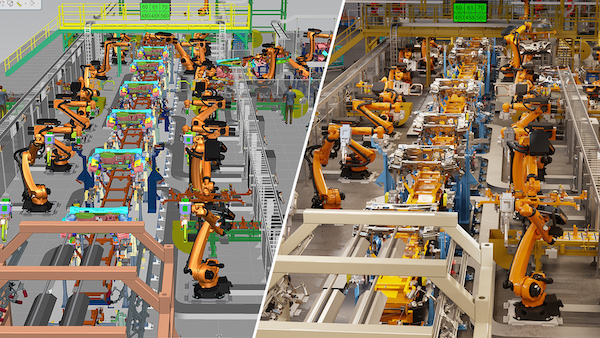

NVIDIA Omniverse and AI are ideal computation engines to represent the comprehensive digital twin from Siemens Xcelerator, claimed the company. The addition of the Omniverse simulation engine to the Siemens Xcelerator partner ecosystem will accelerate the use of digital twins that can deliver productivity improvements across product lifecycles, they said.

Digital twins could lead to industrial transformation

“Companies of all sizes will be able to employ digital twins with real-time performance data; create new industrial IoT solutions; leverage actionable insights from analytics at the edge or in the cloud; and tackle the engineering challenges of tomorrow by making visually rich, immersive simulations more accessible,” added the companies.

“Photorealistic, physics-based digital twins embedded in the industrial metaverse offer enormous potential to transform our economies and industries by providing a virtual world where people can interact and collaborate to solve real-world problems,” said Busch. “Through this partnership, we will make the industrial metaverse a reality for companies of all sizes.”

“For over a decade, our digital twin technology has been helping customers across all industries to boost their productivity and today offer the industry’s most comprehensive digital twin,” he said. “When Siemens Xcelerator is connected to Omniverse, we will enable a real-time, immersive metaverse that connects hardware and software, from the edge to the cloud with rich data from Siemens’ software and solutions.”

Article topics

Email Sign Up