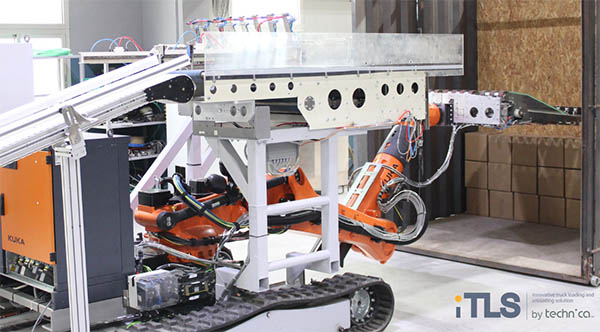

Robots for loading and unloading trucks are still emerging, and they are getting smarter. GreyOrange Inc. and Technica International this week announced a new partnership to combine Technica's iTLS technology with GreyOrange's GreyMatter fulfillment orchestration platform.

The companies claimed that the combination of Technica's innovative truck loading and unloading system and the GreyMatter robot-agnostic platform will improve dock efficiency and speed. They added that their integrated offering can improve efficiency and safety, as well as enable scarce workers to focus on higher-value tasks.

“Due to increasing needs for delivering goods from warehouses to retailers, introducing this new technology with the robot is vital for increasing efficiency, higher profit margins, and lowering carbon footprint by decreasing truck traffic,” stated Tony Haddad, founder and chairman of Technica.

“We are thrilled to join forces with GreyOrange to help make this labor-intensive part of the fulfillment process safer for workers by enabling smart robots to complete the manual tasks of loading and unloading,” he added.

Technica offers customized automation

According to Industrial Safety and Hygiene News, 25% of all industrial accidents occur at the loading dock.

The labor-intensive and manual nature of truck loading and unloading, compounded by poor user ergonomics for heavy loads, frequently results in low vehicle fill rates and high dock turn-around times. This creates inefficiencies at both ends of the warehouse and takes a toll on workers, which can increase accidents, noted GreyOrange.

Technica said it delivers “innovative, customized, and high-quality solutions and turnkey lines” designed to help customers to improve their operational efficiency and increase their production capacity. The company has offices in Bickfaya, Lebanon; Warsaw, Poland; and Montreal, Quebec.

Industry sectors served by Technica include food and beverage, chemicals, glass, plastic, dairy, pharmaceutical, home and personal care, paint, education, and logistics. The company said its customers include Procter & Gamble, Coca Cola, Heineken, Pepsi, Henkel, Unilever, Nestle, al Marai, and Danone.

Other vendors working on robotic palletizing and truck loading and unloading include Boston Dynamics, Dextrous Robotics, and Honeywell Intelligrated.

GreyMatter and iTLS promise to increase efficiency

iTLS—Powered by GreyMatter can enable 99% palletization efficiency and accuracy when forming rainbow pallets, said the partners. It can also improve ergonomics to eliminate worker fatigue, reduce dock turnaround times by up to 150%, and improve productivity by up to fourfold for truck loading and unloading.

“Supply chain and logistics leaders now have another avenue to meet global challenges, including the current labor shortage, as cooperative robotics-human solutions are increasingly recognized by both workers and leaders as essential tools for supporting the workforce,” said GreyOrange.

The new system is fully CE-compliant and is compatible with all standard container sizes, said GreyOrange and Technica. It can handle cases, cartons, totes, bags, and more, they added.

“By transforming one of the most time-consuming and labor-intensive processes in the warehouse through partnership with Technica, our fulfillment platform now delivers the most comprehensive warehouse solution in the market,” said Samay Kohli, co-founder and CEO of GreyOrange. “We enable smart robotic intralogistics for every process step in the warehouse, offering supply chain leaders a fully integrated solution for significant productivity, speed and efficiency gains in a matter of weeks.”

Founded in 2012, GreyOrange said its GreyMatter hardware-agnostic platform responds to customer orders in real time as well as proprietary and certified third-party hardware. The Atlanta-based company said its systems offer a competitive advantage by increasing productivity, empowering growth and scale, mitigating labor challenges, and reducing risk and time to market.

GreyOrange also said it can create better experiences for customers and employees. The company, which closed on $110 million in financing in May, employs more than 800 people with offices and partners across the Americas, Europe, and Asia.

Article topics

Email Sign Up