Until recently, small to midsize distributors weren't expected to invest in high levels of automation, but changing customer expectations driven by e-commerce and improving technology capabilities have brought robotics within reach. Goods-to-person and robot-to-goods picking systems can now affordably deliver the same levels of service for business-to-business purchases as for business-to-consumer ones. One example is Top Notch Distributors Inc., which has deployed robots from 6 River Systems.

Honesdale, Pa.-based Top Notch Distributors is a wholesale distributor of architectural door hardware to residential and commercial dealers. As recently as eight years ago, the company was operating without a warehouse management system (WMS) across its network of four distribution centers (DCs).

Today, Top Notch is using nine autonomous mobile robots (AMRs) in its Carson City, Nev., facility and 13 in St. Charles, Mo. The Missouri facility also features a new rack and conveyor system designed and implemented by Kuecker Pulse Integration. Top Notch plans to introduce more AMRs in Mansfield, Mass., in 2022.

“Technology is evolving so quickly and constantly changing,” noted Patrick Houlihan, director of operations at Top Notch. “But we saw AMR technology as the best fit for our culture and goals because robotics didn’t replace any employees. AMRs allow our existing employees to do more for our customers without us constantly hiring and training more and more people.”

He added that the Chuck robots from 6 River Systems (6RS) are addressing three simple but critical issues in Top Notch’s DCs.

“We’re operating much more efficiently with less labor and in operations that are significantly safer,” Houlihan said. “Our employees are able to focus even more on the customer and getting orders fulfilled correctly to our customers’ specifications.”

Automation also enables Top Notch to add robots to its existing fleet to meet future growth, and it is easy to train new associates on the technology, said Mike Strauss, chief operating officer and the executive sponsor of the projects.

“In Missouri, we stock 20,000 unique items,” he said. “It used to take three to six months before a new employee was up to speed on the layout of the facility and understood those different items. Our AMRs are as intuitive as an iPhone. We can bring in someone new, and they’re picking in hours and get to know the facility in a few weeks.”

Top Notch focuses on service

Top Notch Distributors may be a small to midsize enterprise (SME), but it claims to be the leader in the architectural door hardware industry, representing more than 100 brands of residential, commercial, and electronic access-control systems.

The company was founded in 1975 by Chuck and Wanda Jurgensen, who worked out of a barn in the rural Northeast Pennsylvania town of Honesdale. They focused on offering customers the best available hardware and the “pursuit of excellence in service.” They knew that by giving their employees the autonomy and authority to do whatever it takes to satisfy each and every customer, it would create customer loyalty. Customer service became the foundation of Top Notch’s mission.

Today, Top Notch offers one- to three-day delivery throughout the U.S. from four locations. The Missouri facility is the largest at 100,000 sq. ft., followed by Nevada at 55,000 sq. ft.

The Pennsylvania DC is 30,000 sq. ft., but an additional 15,000 sq. ft. is available in another building located across the parking lot. Top Notch acquired its 38,000-sq.-ft. Massachusetts facility with a Boston-based company five years ago. Throughput is 3,000 orders and 4,000 packages per day at peak.

“In addition to a wide selection of product, Top Notch offers customization and value-added services,” said Houlihan. “For example, they will rekey locks for a dealer who orders a number of doorknobs for a job before shipping. That way, the customer doesn’t have to spend time and resources rekeying on the jobsite.”

“Our employees know our customers and our products,” he noted. “It’s difficult for us to use a lot of temps because an employee needs to understand what they’re picking off the shelf.”

Taking steps to optimization

Until 2015, Top Notch's facilities had minimal automation, which is not uncommon. It didn’t have a WMS or bar code-directed picking. Orders were picked to carts from paper. Storage and picking were in a centralized area, and picking from the top levels of a rack or shelf often meant going up and down rolling ladders.

With growth and the challenge of finding warehouse labor, that approach was no longer sustainable.

“A lot of our processes were simplistic: pick, pack, and ship,” said Strauss. “But we wanted to build the commercial side of our business, which is a more complex product portfolio with a lot of customizable options for customers.”

One of the first steps toward optimization was to implement a new enterprise resource planning (ERP) system with a WMS that would allow further integration with modern platforms. Employees still picked from paper, but they could scan products at putaway and picking to get more accurate inventories.

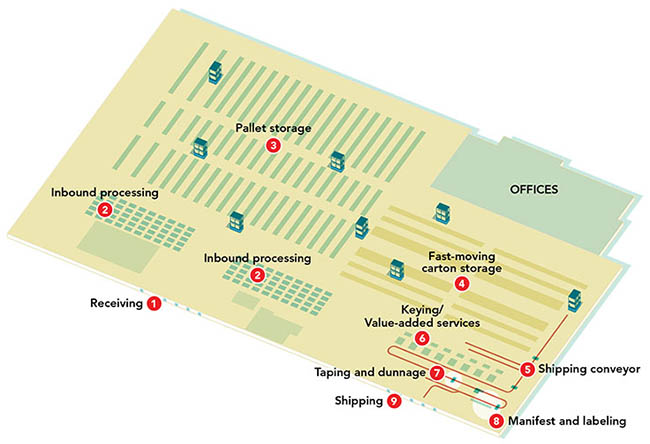

In addition, Top Notch identified the most popular items and moved them to the floor level to make operating safer and clear warehouse congestion. A short stretch of conveyor that diverts items to a value-added processing area and to shipping followed.

A re-slotting initiative eliminated ladders by bringing items closer to the ground level. The facilities also feature case flow near the conveyor system for the fastest-moving items. Top Notch handles more than 80,000 SKUs.

Today, an area is designated to automatically add dunnage and then tape and label an outgoing parcel. Finally, weighing and cubing technology enabled the WMS to recommend the right box for an order.

The conveyor and packing automation addressed a bottleneck related to shipping. But with 20% annual growth, “we never had enough people to staff the business, so we had to keep bringing in and training new people,” recalled Houlihan. Order selectors were still walking seven miles a shift to pick to carts.

Researching robots

In 2019, Top Notch began to investigate picking technologies. Houlihan said the company had several goals for the project:

- Improving space utilization and storage optimization

- Creating a safer and more ergonomic working environment, including eliminating ladders to the extent possible

- Improving efficiency through reduced employee travel

- Creating a foundation to enable the company’s strategic growth plans and overcoming facility capability limitations

The company did investigate some alternatives to AMRs. They include goods-to-person automation, voice picking, light-directed picking, putwalls, conveyors, and smart carts.

According to Strauss, internal considerations included the capital investment required to implement and deploy those systems, the operational benefit each could provide over the next five to 10 years, and the cultural impact on associates.

Top Notch also considered the change management that would be required to deploy and operate the systems.

6 River Systems impresses

At ProMat in April 2019, a team from Top Notch met with representatives of Waltham, Mass.-based 6 River Systems. The team also visited a 6RS customer in the Chicago area to see its system in action. When compared with the alternatives, AMRs appeared to be the best fit, said Top Notch executives.

“Our business model is old-fashioned wholesale distribution. We buy in bulk and receive pallets,” explained Brian Phillips, manager of the Missouri facility. Phillips, who had experience running large, highly automated distribution centers, was part of the team at ProMat.

“At least 80% of our business is case picking,” he said. “6 River was the best suited for case handling.”

Another selling point occurred during a visit to a 6RS customer in New Jersey, according to Strauss.

“The gentleman who gave us the tour took us down to the floor and had us pick,” he said. “With zero training, we were following the robots and picking live orders within 10 minutes. That was a powerful experience.”

Top Notch worked with 6 River Systems for more than a year to fit AMR technology to its processes and IT systems. Over that time, “our operations and IT teams visited multiple sites and had the chance to speak with others using their technology,” said Houlihan. “Their analysts visited our locations, and we shared data and information with them to make sure this was a good fit.”

Once the decision was made to go forward, the goal was to go live in March 2020. Then, COVID-19 intervened.

The teams at Top Notch and 6RS worked remotely to build the application programming interface (API) and integrate the systems.

Initial deployment done in phases

The project got under way in May 2020. When the robots arrived in Carson City, 6 River Systems gave the Top Notch maintenance team remote instructions on how to set them up.

The Nevada facility went first because Top Notch was in the midst of moving into its new DC in Missouri. The rollout took about three weeks because of the pandemic, according to Houlihan.

“We had to quarantine about a third of our warehouse staff for a brief time due to a COVID scare, including the onsite consultant from 6 River, but we continued to work remotely during that period,” he said.

According to Mike Saraceno, manager of the Carson City distribution center, the facility needed only minimal preparations to work with the Chuck robots. The teams installed new electrical panels to handle the power requirements for rapid charging, put down some striping to create parking spots for the robots, and created an aisleway for induction on the conveyor.

The teams also developed a process to prep the carts with the shipping boxes required for orders so associates could begin picking as soon as the carts were deployed. Finally, Top Notch readied its associates for the introduction of a new technology.

“We held a number of meetings and showed them how the robots worked with videos,” Saraceno said. “By the time the robots arrived, they were confident it was going to make things run more smoothly, and they were eager to begin working with them.”

Another selling point to the staff: No one was laid off as a result of the robots. Instead, they allow the facility to grow its business without growing its staff.

Within a few days of receiving the robots, productivity was nearly 25% ahead of where it had been. Within a month after the 6RS trainer's departure, the facility was exceeding the projected numbers.

From Nevada to Missouri

The Nevada facility laid the groundwork for the DC in St. Charles, Mo., which was ready to operate in the fall of 2020. In fairly short order, order selectors had doubled their picking rates with robots, said Brian Phillips, manager of the Top Notch facility.

Today, employees are walking about 3 miles a shift, and the facility has tripled its former picking rates, he said. Phillips added that his best order selectors can pick as much as four times the previous average.

“If we have a busy day where our orders increase by 25%, we can handle it with one additional person in picking, where we would’ve added two or three in the past,” he said. “There are goods-to-person technologies that will get significantly more lines per hour than we are picking, but those rates aren’t necessary for our operations.”

About three months into the implementation, Phillips made a change to the process that has since been adopted by the Nevada facility. 6 River Systems' software receives orders from the WMS and then optimizes the pick path based on the work it has to execute. Phillips’ team realized the robots were more efficient when they had a large batch of orders to analyze.

So they began postponing picking until later in the day. That was one factor in improving efficiency. A second was using more than one robot to pick large orders. As an AMR completes its task, it delivers its load to a consolidation station where boxes are staged until the entire order is ready for completion.

Phillips noted that 6 River is now essentially the WMS for the facility Its dashboard is providing analytics he didn’t have before, such as the productivity of individual order selectors, how many orders are being worked on at any given moment in time or estimates of how much labor will be required to fill a batch of orders.

Top Notch looks to leverge robotics investment

While many companies are using robotics-as-a-service (RaaS) models to lease their fleets, Top Notch bought its fleet of nearly 20 robots.

“Given low interest rates and our assumptions on the operating life of the carts, buying them made the most sense for our operations,” says Strauss.

With more than a year of experience, Top Notch is exploring ways to leverage the investment. For instance, it is exploring the use of the fleet for replenishment.

In addition, because labeling is now a potential bottleneck with higher picking rates, Top Notch is exploring whether it can label shipping boxes before picking as part of the cart prep process.

Both Strauss and Houlihan credited their ongoing relationship with 6 River Systems as a key to their success with AMRs. “We have weekly calls with them, even if it’s just a few minutes to check in,“ says Strauss. “It’s been a tremendous partnership.”

They both cited the quick training time for new associates in a very tight labor market one of the benefit that AMRs have brought to their operations.

AMRs have also positioned Top Notch for growth. “We’re operating more efficiently with less labor in operations that are significantly safer,” said Houlihan. “And, we’re capable of scaling for more growth in the years to come.”

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up