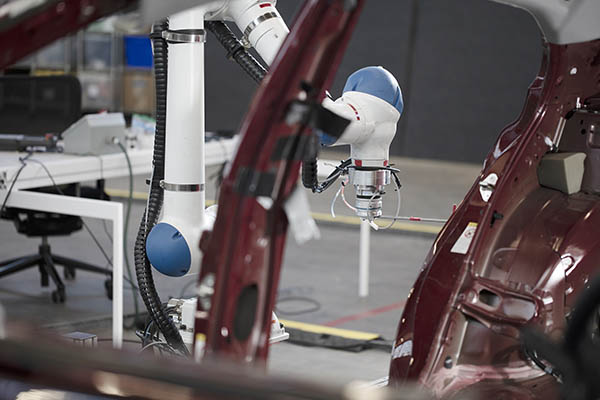

Toyota Motor North America has turned to Symbio Robotics Inc. to make better use of the industrial robots on its assembly lines as it shifts to electric vehicles.

Toyota is using the SymbioDCS software framework to program its industrial robots to automate assembly processes and to better take advantage of the robots' artificial intelligence capabilities.

“Symbio’s AI-based software gives Toyota’s team real-time control of our industrial robots and provides even more flexibility to help meet changing customer and market demand,” said Pascal Renouil, general manager of advanced technology at Toyota Motor North America.

AI software unlocks new robot capabilities

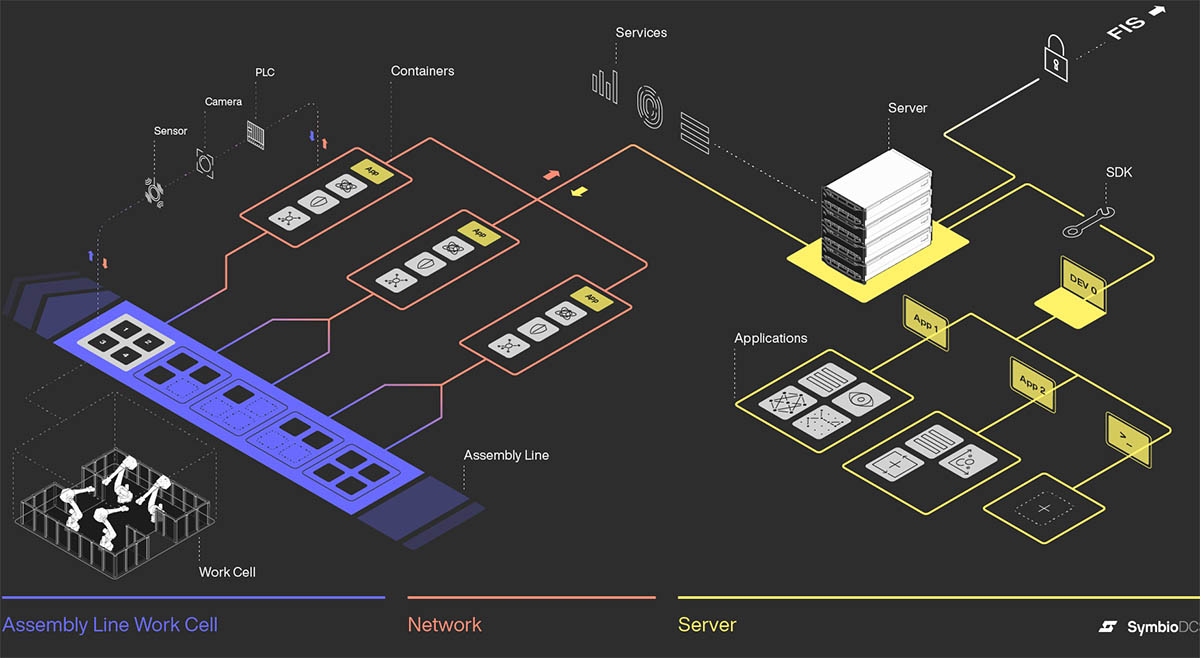

SymbioDCS is a middleware and Python framework intended to simplify the programming of industrial robots and improve human-robot collaboration, according to Symbio.

Robot programmers can use its real-time sensor data with advanced-control software, resulting in more capable and flexible robots, the company said.

Founded in 2014, Emeryville, Calif.-based Symbio's primary audience for its product is the manufacturing industry.

In May, Ford Motor Co. teamed up with the company and deployed an AI-controlled robot at its Livonia Transmission Plant.

Toyota is taking advantage of the technology on some of its highest volume production lines, including for its Camry, RAV4, Sequoia, and Tundra models, Symbio said.

“Engineering teams at Toyota are leveraging Symbio’s technology, expertise and best practices of artificial intelligence to increase efficiency, improve quality, and reduce ergonomic hazards,” said Max Reynolds, co-founder and CEO of Symbio, this week.

Symbio said Toyota is using its moving-line technology, where robotic assembly is done as vehicles are carried down an active production line. Symbio software is also used to perform tasks, such as wax application, without making stops.

Demands increase as EV market grows

“Toyota is preparing for future market needs as demand increases in the area of vehicle electrification,” Renouli said. “Partners like Symbio support Toyota’s goal of providing a diversified range of carbon-neutral options to meet current and future customer needs.”

Data shows the global electric vehicle market size is anticipated to grow from $287 billion in 2021 to $1.3 trillion in 2028. Other reports found that automakers plan to spend an estimated $515 billion over the next five to 10 years to develop and build new battery-powered vehicles and shift away from combustion engines.

“Growth in the EV sector is forcing both traditional automakers and new electric vehicle companies like Tesla and others to find ways to ramp production faster,” said Ryan Kelly, manufacturing and supply chain technologist at The Association for Manufacturing Technology.

“By working with technology partners like Symbio, OEMs are using better automation to redefine their manufacturing processes and gain production line efficiency, agility and quality,” he added.

Article topics

Email Sign Up