As e-commerce volume has exploded, businesses are looking for the best automation to help them fulfill orders and meet customer demand. They need reliable technology to process digital orders with speed and accuracy, as well as to coordinate the growing number of robots in dynamic warehouses and distribution centers.

Although many retail purchases have moved back to brick-and-mortar stores as the COVID-19 pandemic began to ease in the U.S., about 20% of sales occurred online in the second quarter of 2021, reported Digital Commerce 360.

Retailers and logistics companies are under pressure to improve throughput while maintaining worker safety. Developers have responded to this need with new robots and software.

Processing orders optimally

Researchers at the Viterbi School of Engineering at the University of Southern California recently collaborated with Shanghai University of Finance and Engineering. They studied online shopping experiences and created a system that would enable JD.com to optimize robots within warehouses as they scurry about processing orders.

The intent was to allow robots to move quickly without any collisions. The research team developed a mathematical method to optimize the combination of steps with a finite set of solutions.

The system that the USC and Shanghai University team devised allows JD.com's robots to accurately fulfill orders for same-day delivery. It also allowed the company to process 10 times the normal quantity of product orders while rapidly adapting to the unexpected shocks and demand caused by the worldwide pandemic.

As a result of the optimization, JD.com said it was able to reduce storage costs by about 50%.

Implementing augmented reality

As automation becomes more prevalent in warehouses, humans and machines must interact smoothly to maximize productivity. However, close collaboration in real time can be a challenge.

Even as optimization software for warehouse robots becomes more common, other innovations can be combined with it to deliver even greater value. Take, for example, augmented reality (AR).

The State University of New York at Binghamton studied ways to bridge the gap between human communications and mobile robots for OPPO, a consumer electronics and mobile communications company. They found that AR could allow people to observe and direct multiple robots.

Augmented reality technology uses digital visuals in combination with audio and other stimuli to simulate a world view. Human workers can use it to observe the robots' current locations and provide feedback as to what actions and moves the robots should take next.

In the case of OPPO, Binghamton University researchers found that AR can go beyond simply visualization. Augmented Reality for Robots Collaborating with a Human (ARROCH) can help a person interact with a robot and what it's currently doing or direct it to do something else such as make a delivery.

Thus, there's the opportunity for workers to provide bi-directional communications on the robot's intended path or behavior. It's one of the first times that such an interaction has been put into use, said the researchers.

Performing dexterous tasks in the warehouse

Yet another emerging technology is allowing robots to perform very dexterous tasks. This requires some careful mechanical design and artificial intelligence to provide precise robotic manipulation.

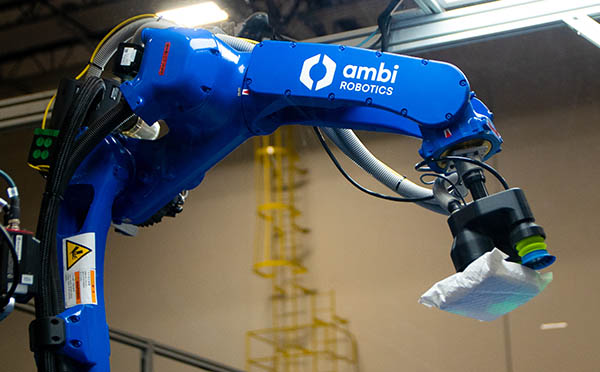

Prof. Ken Goldberg and four graduate students at the Engineering Department at the University of California, Berkeley, worked to improve suction-based grippers. The AmbiSort system is based on the Dex-Net (Dexterity Network) deep learning program created by Berkeley researchers to train robots to grasp a wide range of objects. This has been a challenge for pick-and-place applications.

The system can “grasp, scan, and place objects at twice the speed of human workers,” said Goldberg. Ambi Robotics' AmbiKit can apply this dexterity to assemble subscription boxes and gift sets, as well as conduct more complex assembly operations.

Practical applications drive research

All of the research projects above are driven by an upsurge in e-commerce demand and worker shortages. In addition to dull, dirty, or dangerous tasks, robots can help augment human capabilities to improve working conditions and productivity. But performing tasks such as moving items in distribution centers, interacting with multiple machines, and dexterously assembling or picking assorted items requires innovation.

Each of the projects described above represents just a sampling of the attempts to bridge the gap between R&D and commercial needs. As robotics proves its value across industries, the development and use of fleet management and optimization software, augmented and virtual reality, and machine learning will only grow. The benefits have yet to be fully realized.

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up