The COVID-19 pandemic is arguably the most prolonged and harshest disruption the supply chain industry has seen in the last few decades.

It has been quite a journey for businesses and warehouses from reacting to the situation, navigating operational changes through the lockdown, such as social distancing, and preparing along the way for the eventual re-opening as vaccine trials raise the hope of the end to the pandemic.

As we begin to turn a corner, it is paramount for business executives and supply chain leaders to envision with sufficient clarity what the next normal will look like. They must plan on how best to position a new beginning in order to emerge victorious in the competitive market where survival often is the first hurdle to cross.

In this article, we’ll build the case for a digital warehouse of the future.

As we take stock of the impacts and trends created by the pandemic on the warehouse function to envision the next reality, in many ways the trends are the same as they were pre-COVID, but represent a more accelerated, amplified and acute version of those trends.

Warehouse operations feel the pressure

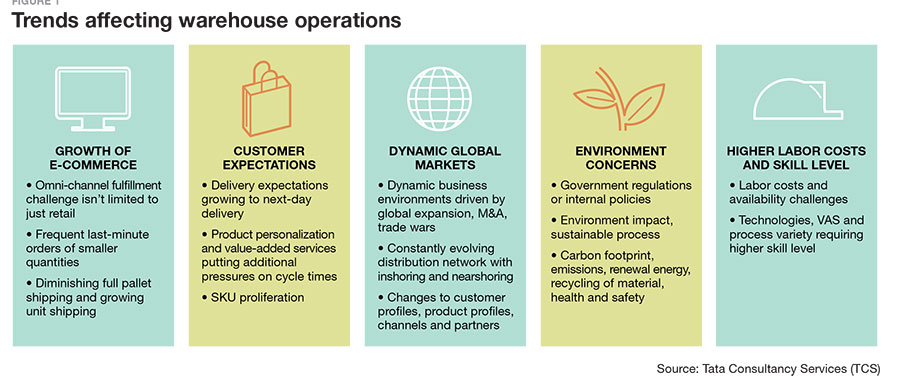

Warehouses were under pressure from a variety of factors before the pandemic. COVID has accelerated them (see Figure 1). They are as follows.

E-commerce. E-commerce has posted double digit growth for the last several years, a trend that is poised to continue. As if the challenges of delivering on a customer experience to retail consumers weren’t enough, the adoption of online channels in B2B is expanding as well.

With the convenience of B2B and e-commerce, business and consumer buying behavior continues to shift in terms of making smaller and more frequent purchases with ever shorter lead times. The role of the warehouse continues to expand and elevate further with e-commerce.

Finally, the pandemic has accelerated the preference for a no-touch buying experience.

Customer expectations. Along with online buying, customer expectations have continued to grow, including demand for personalized features/terms, lightning fast deliveries and flexibility to make no cost shipping and order/return changes.

That puts multi-point pressure on warehouse operations stretching them in a lot of different directions to drive the expected perfect order and customer satisfaction targets. The underlying conflicts from the proliferation of personalized products, the growth of each picking and next hour deliveries are creating hard-to-optimize warehouse equations.

The uncertainty and disruptions of the pandemic drove customer behaviors such as the stockpiling of critical products to hedge the choppy upstream demand or canceling/cutting non-critical items to conserve cash. Customers look to pass that uncertainty on to their suppliers by demanding unprecedented flexibility in terms of abrupt demand changes. These behaviors/expectations are amplifying the pressure on already strained warehouse operations.

Dynamic markets. The competitive and dynamic nature of the business environment continues to expand to new global markets, with the addition of new channels and M&A activities. At the same time, geo-political trade wars and narrowing global labor cost arbitrage are driving change in the business mindset, such as the China Plus One strategy, calling for companies to invest in China plus at least one other country rather than put all of their eggs in the China basket.

These forces drive real changes to the distribution network, customer profiles, product profiles, channels and partners. This is resulting in a large number of suboptimized process variations for warehouse operations.

The pandemic has also intensified the quest for alternative regional supply sources to make the supply chain more resilient to disruptions by decoupling through in-shoring or near-shoring.

Environmental concerns. While economic swings, cost pressures and politics keep the environmental debates going, the recognition of the long-term importance of a sustainable supply chain operation is both growing and inevitable.

Government policies and customer awareness elevate the need and benefits of purpose-driven responsible supply chain practices. It also creates a positive influence on an organization’s brand, reputation, customer satisfaction and loyalty. Warehouse operations certainly have a fair share obligation to devise ways to reduce carbon footprint and waste of resources through efficiency and innovation.

The pandemic is not expected to displace the long-term importance of environment friendly logistics operations.

Higher labor costs and skill level. The low unemployment rate, expansion of e-commerce and an aging workforce have contributed to a strained labor pool for warehouse operations. The required skill level for warehouse operators is growing with increased process variety driven by factors such as product personalization, M&A, value added services and technology adoption.

The pandemic certainly reduced order volumes for certain sectors and product categories while increasing them for others. However, the need for labor optimization continues to remain important with the pandemic affecting labor productivity and net capacity due to social distancing, additional safety steps, facility lock downs and sick leaves.

Needless to say, these trends create an imminent need for warehouses to reimagine new, smarter ways to create customer value and yet reduce cost. Digitization of the warehouse offers the most versatile and potent war chest of tools to convert the difficult trends into rewarding opportunities to retain and expand the market leadership.

Warehouse digitization redefined

The digitization of business has by far been the biggest area of focus for most business executives in recent years. As a result of the trends we just outlined, digitization of the supply chain, and the warehouse function, is emerging as an important area of focus. While many organizations already have aggressive digitization roadmaps underway, many are in the early process of sketching up the plans and some are yet to start. There is no doubt that the early movers, innovators and effective executors enjoy the lion’s share of the rewards and will push sluggish competitors out on the survival path.

So, what does digitization of the warehouse mean? While it is certainly a well discussed topic, it’s important to revisit it for this article.

Warehouse digitization is about creating new smart and innovative capabilities. This happens by synthesizing systems, data, machines and humans across the distribution nodes using advanced technologies to create tangible customer value, operational differentiation and efficiencies.

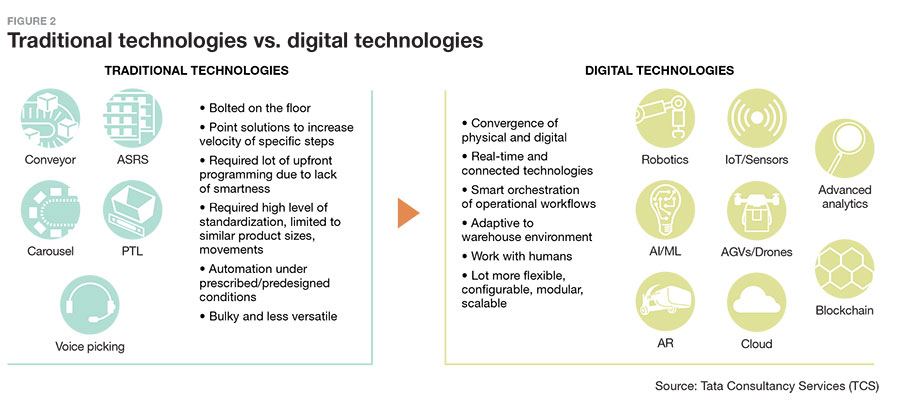

Automation, software, sensors and other technologies have certainly been part of warehouses for the last two decades. Consider solutions such as RF devices, high speed conveyors, sortation, ASRS, carousels, pick to light and voice-directed picking to name a few of the solutions at play. However, traditional automation tools were largely point solutions to increase throughput and velocity of specific operational steps for specific products, customers, transaction types or process scenarios.

In contrast, digital technologies are situationally-aware and continually learn to orchestrate and optimize warehouse processes dynamically for each scenario presented and in a configurable, continuous and real time manner to drive the desired outcomes. They promise to bring smartness and flexibility to today’s market demands. Digital technologies present a lucrative opportunity for virtually all warehouse operations; but in especially for complex warehouses, they may be the only realistic path forward (see Figure 2.)

Warehouse digitization can create new capabilities to tackle the trends of the future:

- dynamic orchestration of the distribution network to support abrupt demand changes;

- optimized throughput to support high order volume of small quantities across a wide SKU assortment;

- optimized cycle time and velocity to support next hour shipment of products personalized to order;

- drive down operational costs through efficient and collective optimization of man, machine, space and energy resources; and

- create a differentiating customer experience through fulfilment accuracy, visibility, reliability and speed.

Critical principles of a digital warehouse

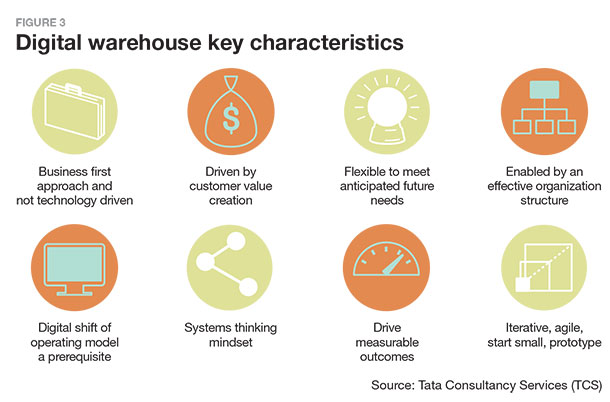

The first obvious, yet foundational, principle is that any warehouse digitization must be a harmonized element of a broader digitization strategy of the business and operating model. The holistic approach to a digital business model and its cascading alignment to digitize the warehouse function is key to create an overall competitive edge that is not short-lived nor easy to erode (see Figure 3).

While there are a lot of exciting new technologies, it’s important not to get carried away by shiny objects. Remember that technology-led initiatives carry a high risk of becoming obsolete when business dynamics and market demands change. The loss of capital from unfruitful initiatives can leave an organization worse off than the dreaded status quo.

While there are a lot of exciting new technologies, it’s important not to get carried away by shiny objects. Remember that technology-led initiatives carry a high risk of becoming obsolete when business dynamics and market demands change. The loss of capital from unfruitful initiatives can leave an organization worse off than the dreaded status quo.

For those reasons, a business’s strategy, vision, objectives, current strengths/differentiators, pain areas and market conditions should provide the overall context for the warehouse digitization, while maintaining a razor-sharp focus on customer value creation.

Beyond that, warehouse digitization must also have the flexibility and configurability to serve expected future needs. The warehouse of the future must be designed to reconfigure itself to the dynamic nature of product profile, customer profile, transaction profile and warehouse layouts.

Systems thinking is also important here. You want to ensure the warehouse digitization does not end up as a mixed bag of singular unconnected victories that keep shifting inefficiencies across various sub processes

and functions.

The capabilities and use cases forming the future warehouse should be mapped to measurable outcomes and KPIs that are in complete alignment with the business strategy and customer value creation.

Use cases, or the art of the possible

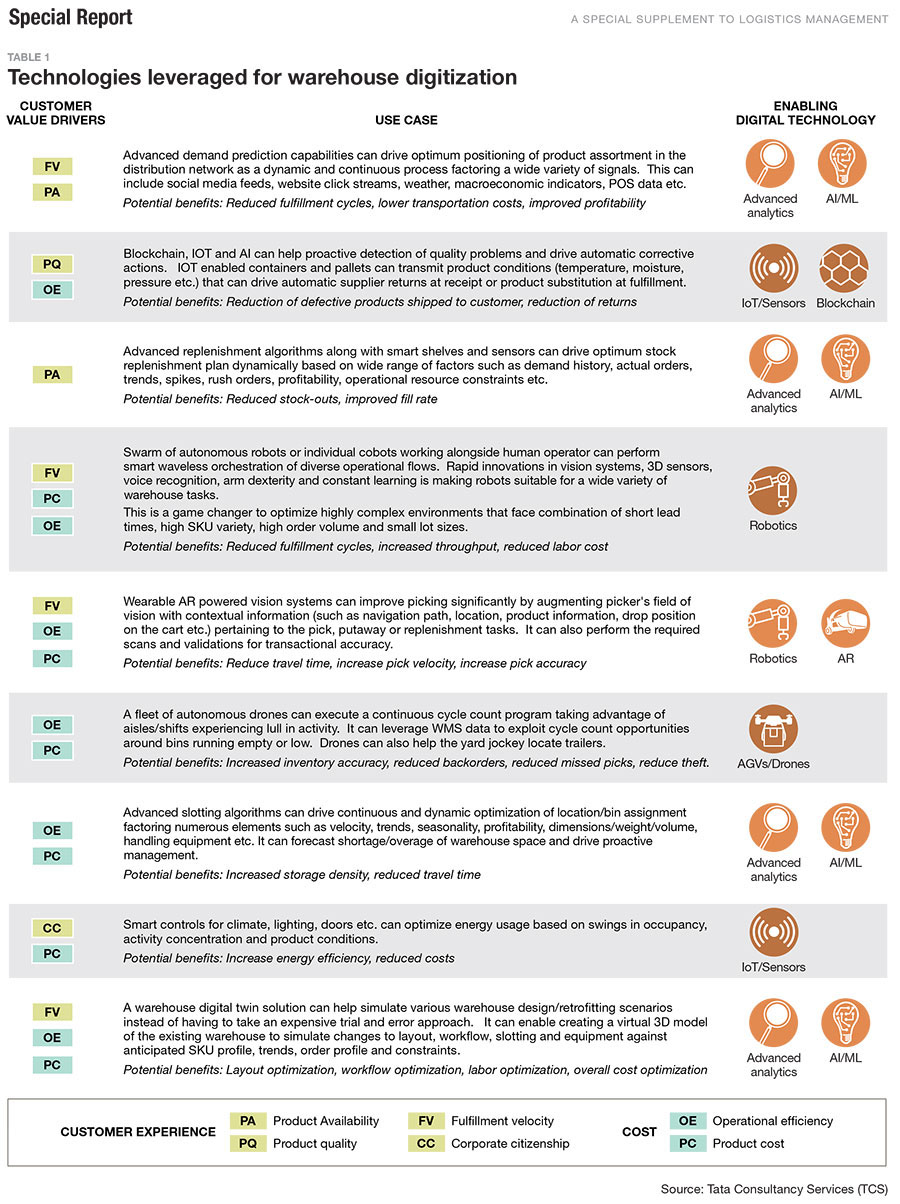

Now that the foundational principles are in place, next comes the exciting part: Envisioning value creating warehouse use cases and capabilities that leverage digital technologies to drive desired outcomes.

Now that the foundational principles are in place, next comes the exciting part: Envisioning value creating warehouse use cases and capabilities that leverage digital technologies to drive desired outcomes.

The digital technologies in question here need no introduction. They have been in conversation for a few years and have already been converted into reality for many organizations, and include AR, IOT/Sensors, robotics, blockchain, AGVs, drones, AI/ML and voice recognition.

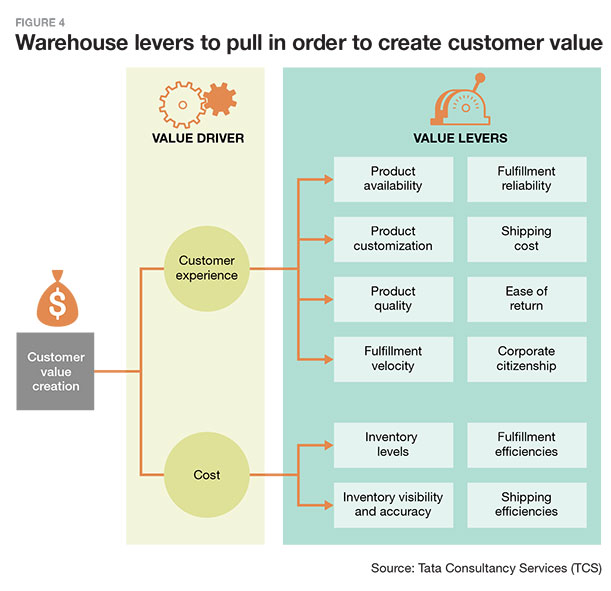

The first step to creating the warehouse of the future is to answer the million-dollar question: What do your customers value most when they engage with your business to meet their needs? The answer to that question can tilt the customer to you compared to your competition, and build a long-term loyal, mutually beneficial relationship.

The cost of the product and shipment are the basic sources of customer value. Beyond that, typical sources of customer value delivered by a warehouse stem from transaction-linked capabilities that enable successful deliveries and returns, such as ease, flexibility, velocity, visibility and reliability. Customer value can also be derived from product-linked features such as availability, personalization and quality. Needless to say, each business is unique and requires a clear definition of customer value that is specific to their product offerings, selling models, customer segments, markets and channels.

Figure 4 illustrates the typical levers that a warehouse operation can pull to create customer value.

These customer values should drive the definition of use cases and expected outcomes measurable to specific KPI targets. The end result must contribute in the form of operational efficiencies, flexibilities or top line revenue growth.

Table 1 shows how technologies are being leveraged for warehouse digitization.

A roadmap to the digital warehouse

A clearly defined approach is critical for any major transformation initiative. It is even more so for digitization initiatives, given the wide range of possibilities, speed of technology innovation and also what is at stake.

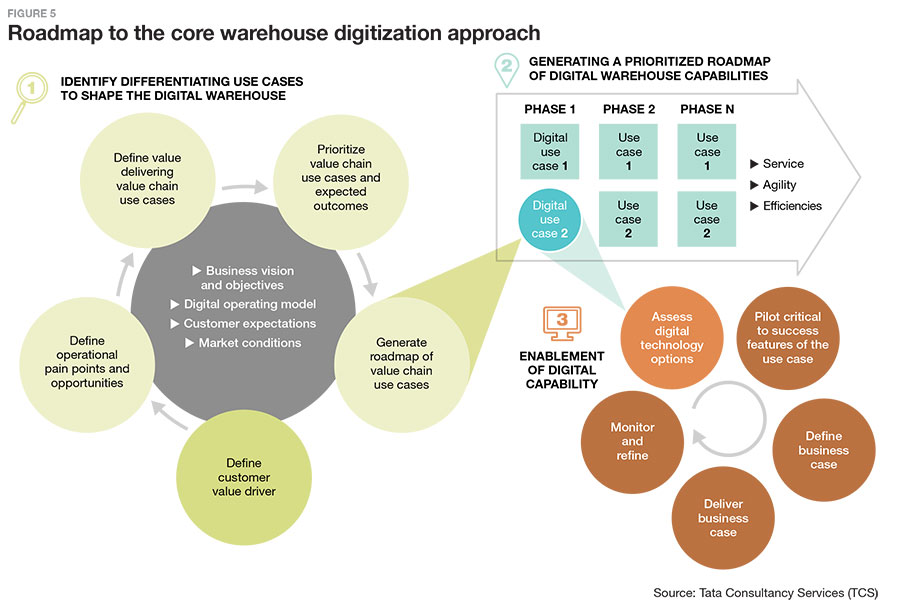

The steps compiled below, and illustrated in Figure 5, represent a roadmap to the core warehouse digitization approach that has worked well in our experience. It recaps and extends what is already covered in this document.

1) Set a clear strategic context. A clear business context covering the below elements creates a uniform view for the cross functional team on what the overall success looks like for the business and the expected direction for the digital warehouse initiative:

- business vision and objectives;

- digital strategy for the overall business and operating model;

- voice of the customer;

- market conditions;

- operational strengths a pain points; and

- guiding principles.

A strong governance of the strategic context is vital to ensure that the right set of business benefits are created by warehouse digitization.

2) Define customer values and outcomes. As outlined earlier, this step ensures that the warehouse of the future is customer centric and outcome oriented. The customer values and experience created by the warehouse function should also be aligned with the overall customer journey to generate a robust experience and brand impression.

3) Define value delivering use cases. Exhaust the last drop of collective creativity and innovation to rethink new sets of warehouse use cases that can produce the specific expectations outlined by the previous step with certainty. The technology choices are daunting, and the breadth and depth of skills required to implement and operate them can expand very quickly to make the right technology choice across all use cases.

4) Use case selection and roadmap. Once a pool of use cases is created, the cost and benefit measures (quantitative and qualitative) are to be compiled for each. A flexible business case framework can be calibrated based on cost-complexity-risk-reward parameters to balance the level of due diligence and agility of the decision. Too often, highly promising use cases get lost in the paralysis of business case analysis in the absence effective tools.

The business case helps rank and stack use cases based on business benefits, effort, complexity, costs, change impact and risk. The end result will create a roadmap that delivers an optimum schedule of benefit realization.

The warehouse use cases with inadequate functional or technical clarity require a targeted proof of concept to mitigate risks before confirming to the roadmap.

5) Agile iterative journey of value delivery. The nature of business transformation is like an endless marathon given the ever-changing business dynamics. The digital warehouse roadmap should be seen as a never-ending, continuous journey to enable new capabilities. The adoption of agile execution methodology is vital to ensure the roadmap stays fresh and reflective of the business needs as they change.

It also makes sense to commission an independent Digital Center of Excellence (COE) within the organization that embodies entrepreneurial spirit and is empowered to evaluate digital use capabilities before they get implemented in full scale as part of the roadmap.

Overcoming challenges

There is a great deal of agreement that digitization of supply chain and the warehouse function isn’t just a buzz word.

The typical challenge with the digital warehouse originates from the fact that the business needs, strategy and the potential use cases are unique to each organization. They aren’t a recreation of cookie-cutter templates.

A warehouse digitization initiative requires a variety of skills such as warehouse domain functional analysts, digital technology specialists, data scientists, agile coaches and change leaders. The skill gap, or availability of technical skills, is a typical challenge for most organizations. A qualified external partner can be crucial in guiding the overall initiative and bridging the skill gap.

Another typical area of challenge is the existence of functional silos with conflicting objectives impeding collaboration and resistance to change. A qualified external partner can help here as well by bringing a fresh outsider perspective, unbiased steering towards the overall organizational victory and facilitating the change.

In conclusion, it is an exciting time with a wide range of digital opportunities awaiting to propel warehouses to a new beginning looking to excel in the post-COVID era.

Article topics

Email Sign Up