Editors’ Picks

Found in Robotics News & Content, with a score of 5.19

…creation. The comprehensive library will allow users to download programming examples and use them to control UR cobots, said Universal Robots. “Our cobots have always been characterized by their intuitive handling,” said Meier. “Their integration into the TIA portal via the Simatic Robot Library now accelerates their integration and implementation into complex production lines. It also makes it easier to combine the UR cobots with technologies like Edge data analyses or cloud services and include them in the monitoring of plant conditions.“ “Siemens' automation group is active in verticals such as automotive, logistics, and food and beverage,” he said. “If…

Found in Robotics News & Content, with a score of 8.00

…that learns in a simulation and doesn’t need expensive programming. The ideal is like an Amazon warehouse—software is making all the decisions, but humans are working side by side with robots and autonomous systems. The mix of manual and automated labor will change and develop over the years as solutions change and develop. The future depends on the first stage, the current stage, working well. Ingredient technologies enabling autonomy Artificial intelligence is one of the key enabling ingredient technologies, but it is not the only one. In the past few years, machine learning, computer vision, and deep learning have enabled…

Found in Robotics News & Content, with a score of 23.25

…in ISO standard G-code format. Those unfamiliar with robotic programming language will no longer require additional training or specialists because the programming can be performed with G-codes. A reliance on a separate teach pendant for the robot is also greatly reduced with the capability of robotic programming and operation through the CNC user interface. FANUC’s QSSR not only makes connecting a FANUC robot through a high-speed Ethernet cable to a machine tool easy, but also simplifies the setup, programming and operation. The QSSR G-code feature is available on FANUC CNC Series Oi-F, Oi-F Plus, 30i-B, and 30i-B Plus. About FANUC…

Found in Robotics News & Content, with a score of 4.48

…want. They generally use the software, operating system, or programming on the robot. For every product we launch, we launch software packages for every single robot out there, so they don't need any additional tools. We have plug-ins for all the cobot manufacturers, which dramatically reduceds deployment time.” What about third-party monitoring software? “We work with differerent vendors and are not limiting ourselves to supplying only grippers or hardware,” responded Hulgard. “We want to be a one-stop shop for every component—including hardware—for applications.” “Last year, the cobot and light industrial market declined by 20%, but we still grew by 47%,”…

Found in Robotics News & Content, with a score of 3.64

…the Fighting Spirit Prize at the National High School Programming Contest with a smartphone-controlled robot; they also earned seventh place in the RoboCupJunior Japan Open rescue division. In discerning how to apply their talent to help the country, Ogasawara and Kumeda formed Team ROK as students at the National College of Technology. Their brainchild was X VEIN, a search-and-rescue drone, which made its public debut at Maker Fair Tokyo 2016. Japanese students Yuki Ogasawara and Ryo Kumeda developed the search-and-rescue drone after the 2011 Great East Japan Earthquake. Image courtesy of Team ROK and Autodesk. Winged for the future “Most…

Found in Robotics News & Content, with a score of 7.48

…our 2020 event, we were really pleased with the programming we’d pulled together, and then March 16 came, and we had to cancel that conference. We also realized the content just wasn’t relevant to the concerns of our members last spring, so we had to take a step back. And, based on everything we’re hearing, we think it’s the third quarter of 2021 before you see live events coming back. Modern: How are you approaching this May’s virtual event? Mikitka: Our focus is always on education, timely presentations and networking. I believe the beauty of our content is that it’s…

Found in Robotics News & Content, with a score of 12.71

…Each SDK package includes a complete set of application programming interfaces documentation, and code samples that enable development partners and manufacturing customers to establish two-way connectivity between Stratasys FDM 3D printers and enterprise software applications. Stratasys has previously introduced support for MTConnect, an industry-standard protocol that enables customers to communicate factory data. However, this standard does not support additional capabilities for sending and receiving printer commands and for remote monitoring. Stratasys is now meeting the need for more sophisticated two-way integration as part of its Industry 4.0 initiative. Initial partners for the GrabCAD SDK program include Link3D, the leader in…

Found in Robotics News & Content, with a score of 9.80

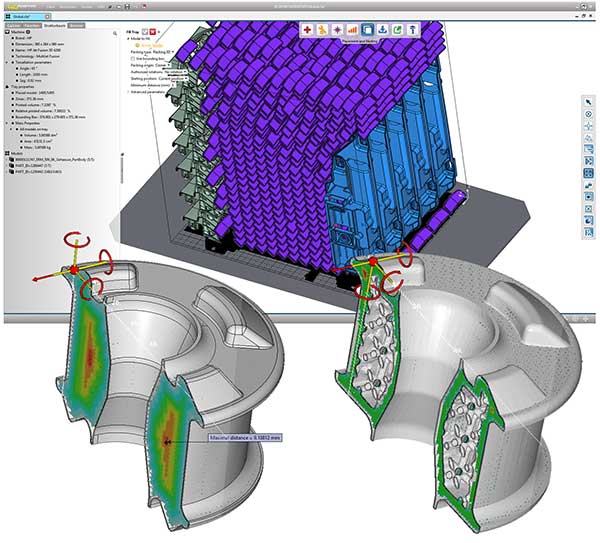

…technology simulates certain human decision-making structures based on the programming and by this means the computer independently processes complex tasks in the area of so called nesting. Optimized component nesting With its new “pack and optimize” strategy, the nesting module of the latest 4D_Additive software version is able to ensure both maximum filling of the installation space and even distribution of the mass to be printed, thus ensuring the most constant possible slice surfaces. The advanced program uses AI technology and imitates the behavior of an experienced user by automatically filling empty areas in the packaging space after pre-positioning. This…

Found in Robotics News & Content, with a score of 7.92

…from tens of thousands of liquid rubber materials, customizing it based on desired durability, flexibility and cure time. After programming the mixing ratio and injection volume, the Inj3ctor fills in the mold, creating a fully-customized, flexible product. The first batch of Structur3d’s new Inj3ctor platform for desktop injection molding is preparing for shipment in Q4 2020 to industry 4.0 manufacturers. The Inj3ctor Platform Bundle includes the Inj3ctor, an Ultimaker S5 3D printer, materials for both, and additional accessories and support.

Found in Robotics News & Content, with a score of 10.42

…challenge by enabling the integration of HP 3D Application Programming Interface (API) with AMFG’s MES software. HP Jet Fusion users will be able to connect directly with their systems through AMFG’s software, track production status and receive critical alerts and information in real time. Integrating machine data This integration between HP systems and AMFG software will help to establish a transfer of data at every stage of AM production, facilitating greater process reliability and quality control. For example, by accessing real-time solution data, including system utilization, failure rate and processing parameters, HP Jet Fusion users can fully understand AM operational…

Found in Robotics News & Content, with a score of 29.54

…the CAD/CAM provider for robotics, to create a complete programming solution for robot additive DED (direct energy deposition). To provide customers with an end-to-end solution for programming robot additive DED, ESPRIT has been working with Alma to bring together advanced toolpath planning in subtractive and additive areas, and technology in robotics trajectory computation and off-line programming of arc welding robots. This solution allows Alma to use the full ESPRIT additive DED cycles such as 3x, 4x and 5x, bringing the software to a new level of support for additive technology, the companies say. The solution also allows ESPRIT to support…

Found in Robotics News & Content, with a score of 12.61

…machine to plan and optimize its numerical control (NC) programming, enable machinists to determine the location of the 5-axis singularity point and avoid it for the first time. When the toolpath generated by computer-aided manufacturing (CAM) software passes through, or near to, the singularity point, the machine tool behaves erratically. The machine tool can vibrate, causing “chatter marks” on the component being machined, which affects the quality of the surface finish. The new release helps predict the singularity point. By predicting the lines of code where there may be problems with vibrations and surface quality, programs can be improved by…