Despite the current hype around artificial intelligence, AI and robotics can help manufacturers—if they're properly integrated. Intrinsic and Siemens yesterday announced that they have teamed up to explore integrations and interfaces between Intrinsic's robotics software, which is designed for easy use of AI-based capabilities, and Siemens Digital Industry's portfolio for automating production.

“Intrinsic’s mission is to democratize access to robotics,” said Wendy Tan White, CEO of Intrinsic, in a press release. “However, robotics is rarely decoupled from the production environment, where the most value is created today.”

“That’s why working with Siemens Digital Industries, an industry-leading automation expert, is an exciting opportunity to bring joint solutions to the market in the future, so many more businesses can benefit from the value that robotics and automation can offer,” she added.

San Francisco-based Intrinsic said its team has expertise in advanced perception, machine learning, and reinforcement learning. The Alphabet company also said its automation engineers and software developers have domain knowledge about industrial robotics.

Intrinsic claimed that its software will make automation accessible to more businesses, entrepreneurs, and developers. In December 2022, the company acquired the commercial division of Open Source Robotics.

Siemens and Intrinsic to bridge IT/OT gap

“Currently, the development and runtime environments for AI-based robotics and automation components differ significantly in their development paradigms and make integration cumbersome,” said Intrinsic and Siemens.

The companies cited the example of deploying capabilities such as pose estimation, robot manipulation, or automated path planning. These are complex processes that typically require teams of domain experts to operationalize, they said.

Siemens and Intrinsic said they plan to investigate new ways to “bridge the gaps between robotics, automation engineering, and IT development.” This will speed up the development process for flexible work cells and “faciltiate their seamless operation,” they claimed.

By improving connections between robotics development and operational software environments, more businesses, entrepreneurs, and developers will be able to use automation—particularly market segments such as small and midsize manufacturers, said Siemens and Intrinsic.

“Siemens is dedicated to bringing IT [information technology] and OT [operational technology] closer together—the key principle of our Industrial Operations X portfolio,” said Rainer Brehm, CEO of factory automation at Siemens. “We are impressed by Intrinsic’s open approach to industrial robotics, and we are excited to explore with Intrinsic how coupling of AI-based robots and automation technology can be further accelerated.”

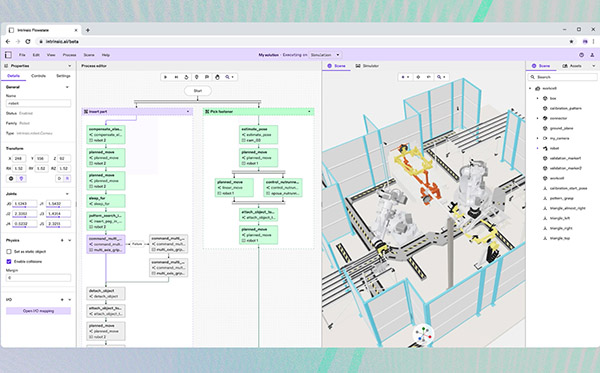

Last month, Intrinsic introduced Flowstate, the first product built on its platform. Flowstate is a Web-based developer environment for taking robotic applications from concept to deployment. The company also announced a collaboration with Comau.

Partners to exhibit at Automatica

Both Siemens and Intrinsic will be exhibiting at the automatica 2023 trade fair from June 27 to 39 in Munich, Germany. Under the motto “Accelerate Transformation,” Siemens plans to show its latest technologies and specific use cases from the world of robotics, making them tangible for visitors in a test zone.

On Tuesday, June 27, from 1:00 to 2:00 p.m. CET, White and Brehm will join the munich_i CEO roundtable titled “Software: Revolution for Automation and Robotics?”

Siemens Digital Industries (DI) said it collaborates closely with partners and customers to drive digital transformation in the process and discrete industries. With its Digital Enterprise portfolio, DI said it provides companies of all sizes with products and services to integrate and digitalize the entire value chain.

Nuremburg, Germany-based Siemens Digital Industries has around 72,000 employees internationally.

Article topics

Email Sign Up