One of the most popular robotics applications shown at this week's FABTECH trade show was welding. Neuromeka Co. this week exhibited its collaborative robot for welding at the metal processing, manufacturing, and finishing event at Chicago's McCormick Place.

Neuromeka said the system can help small and midsize manufacturers, particularly in the shipbuilding sector, which has been grappling with labor shortages and other disasters.

“Neuromeka is a leading provider of robotic solutions, committed to enhancing automation across diverse industries,” said the Seoul, South Korea-based company, which was founded in 2013. “With a focus on innovation and safety, Neuromeka's collaborative robots are designed to elevate productivity while ensuring the well-being of human operators.”

Cobot welding system provides real-time data

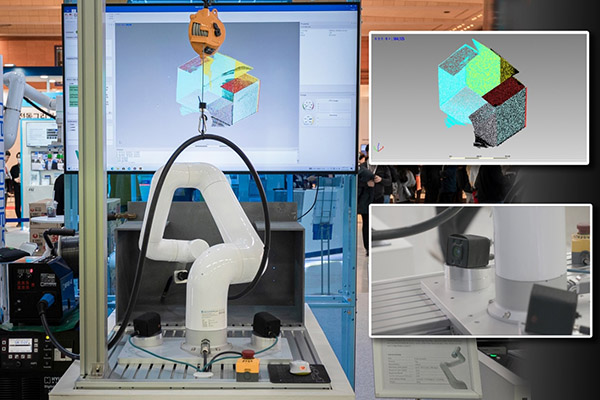

Neuromeka said the cobot welding system it showed at FABTECH is designed for block-welding processes in the construction of large ships. Its features include arc sensor-based welding seam tracking and automatic detection of welding irregularities using 3D cameras.

In addition, the system displays the ship-block and welding seam extraction results in real time on a smart touch pendant. Neuromeka claimed that this enables the easy creation of essential process programs with straightforward settings.

Neuromeka designs Indy for safety

Neuromeka added that its “Indy” six-axis collaborative robot incorporates an automatic stop mechanism upon collision with either individuals or its surroundings to ensure safe coexistence with human operators in shared spaces. The company said the cobot's user-friendly interface and simplified programming capabilities are designed for non-experts.

The National Sanitation Foundation last month granted Neuromeka safety certification for special-purpose food processing equipment and related components in the U.S. The company said this will further accelerate its entry into the North American market for food and beverage automation. It has opened a branch office in Austin, Texas.

Neuromeka last week also announced that it has obtained International Organization for Standardization (ISO) certifications ISO 9001 for quality management, ISO 14001 for environmental management, and ISO 45001 for occupational health and safety management systems.

Editor's note: For more about FABTECH, visit Robotics 24/7's special coverage page.

Article topics

Email Sign Up