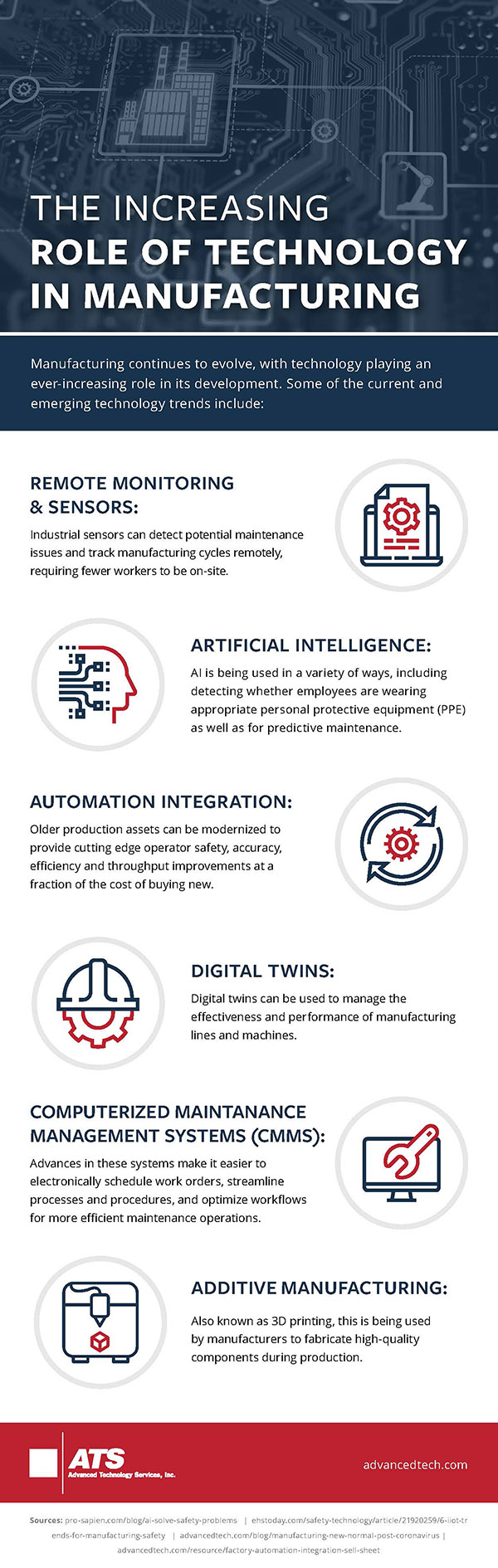

Constant advancements in technology are changing how business is done. The manufacturing industry in particular is becoming more efficient, as production, assembly, and supply chain operations add automation. Learn more about the increasing role of technology across manufacturing in the infographic below.

Technology is affecting numerous areas of manufacturing through a broad range of methods, tools, and processes. They include:

- Remote monitoring and sensors

- Artificial intelligence

- Automation integration

- Digital twins

- Computerized maintenance management systems (CMMS)

- Additive manufacturing

Areas of manufacturing benefiting from tech

Here are some key areas where technology is rapidly increasing, expanding, and changing the face of the manufacturing industry.

Production

Technology such as additive manufacturing or 3D printing is enabling major changes to production processes and capabilities. With advances in materials, 3D printers are now capable of making production-quality parts in any quantity needed, even low quantities, without sacrificing quality or cost-efficiency.

Simulation and digital twins can not only help with prototyping products or laying out factories; they can also be used in training personnel and robots plus managing change and performance.

All of these innovations can speed production and add flexibility throughout the manufacturing process, leading to lower costs and higher-quality products.

Automation

Robotics and automation are evolving and can now be integrated into even more areas of the facility. Collaborative robot arms and mobile robots are able to work alongside human workers safely and flexibly.

With new hardware and software that can communicate and better integrate with different equipment such as conveyors and forklifts, automation can be monitored and controlled more closely. Interoperability among robots is also becoming a priority.

With significant advances, new technologies are continuing to expand in manufacturing. Even in the automotive industry, robotics adoption is still rising, according to the International Federation of Robotics (IFR).

Maintenance

With smart machines, industrial sensors, and full connectivity throughout the facility, maintenance managers and technicians can gain more insight than ever into the real-time performance, health, and status of machinery. Sensors and other condition monitoring tools can be aftermarket or integrated into the equipment, as with many newer machines.

These devices provide ongoing data that can help detect the initial stages of potential failure modes, well before unplanned downtime occurs. This early detection strategy can help technicians to predict potential problems and choose low-impact times to diagnose them and perform any necessary maintenance. A more proactive approach is more cost-effective than reactive maintenance.

Inventory management

Inventory monitoring and tracking systems more frequently and accurately measure usage and the need for spare parts than conventional manual methods. These technologies can also identify the correct parts and tools for maintenance and repair operations, allowing for more streamlined ordering processes.

From the aforementioned sensors and mobile robots to drones and predictive algorithms, the collection and analysis of inventory data can save time over manual, analog inventory taking. Modern inventory systems promise to increase productivity and reduce downtime.

Supply chain

Similarly, technology-driven supply chain systems can provide greater insights into supplier relationships, demand forecasting, ordering, potential delays, and more. Combined with tools like artificial intelligence and robotics, these systems can drive more effective decision-making in nearly all areas of the supply chain.

Supply chain management software can also help optimize relationships and contracts with suppliers based on real metrics and analyses. Even with recent challenges from the pandemic, trade conflicts, and shipping problems, the supply chain is often viewed as an opaque, monolithic area that cannot be changed.

However, today’s emerging technologies are challenging those assumptions and driving greater production efficiencies than ever. For more information on how technology can help manufacturers, and to learn more about the tools and processes that are driving these changes, see the infographic below.

About ATS

Advanced Technology Services Inc. (ATS) is a global industrial services provider with nearly four decades of experience in technology-driven industrial maintenance and parts services. Through its services and technologies, ATS said it is advancing solutions that make its customers’ operations safer, more reliable, and more data-driven.

Article topics

Email Sign Up