Robots are slowly working their way into a variety of applications, from moving goods in warehouses to delivering packages. An increasing shortage of healthcare workers is also prompting the use of caregiving robots.

Right now, these robots are limited to activities like asking questions and monitoring patient safety. They aren’t designed to provide the type of hands-on care a nurse would.

That may change, thanks to the development of 3D-printed “soft” robotics systems at Purdue.

“Unfortunately, the external hard structure of current caregiving robots prevents them from a safe human-robot interaction, limiting their assistance to mere social interaction and not physical interaction,” said Ramses Martinez, an assistant professor in the School of Industrial Engineering and in the Weldon School of Biomedical Engineering in Purdue’s College of Engineering. “After all, would you leave babies or physically or cognitively impaired old people in the hands of a robot?”

Purdue University researchers have developed a new design method for efficiently creating soft robots using 3D printers. Their research was published in Advanced Functional Materials in April.

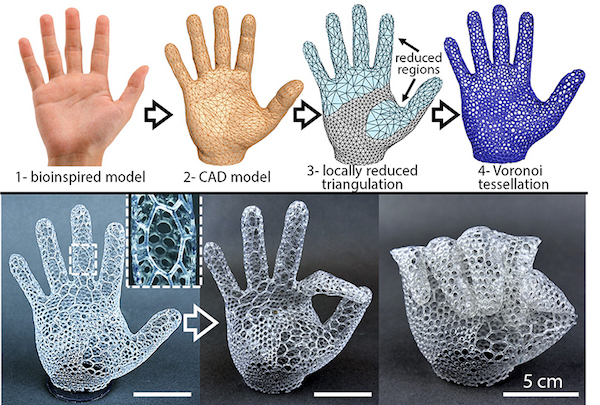

Purdue University researchers have developed a new design method to create soft robots that may help in caregiving for elderly family members. Image courtesy of Purdue/Ramses Martinez

The Purdue team first created a CAD file that includes the shape of the robot. The designer “paints the file to indicate the direction of the robotic joints will move.” Using an algorithm, the researchers then converted the file into a 3D architected soft machine (ASM) that can be printed using any conventional 3D printer.

According to an article on the Purdue website: “The architected soft machines move like humans, except instead of muscles they rely on miniaturized motors that pull from nylon lines tied to the ends of their limbs. They can be squeezed and stretched to more than 900 percent of their original length.”

“ASMs can perform complex motions such as gripping or crawling with ease, and this work constitutes a step forward toward the development of autonomous and lightweight soft robots,” Martinez said. “The capability of ASMs to change their body configuration and gait to adapt to a wide variety of environments has the potential to not only improve caregiving but also disaster-response robotics.”

You can see the system in action here, and more videos on the research team’s YouTube channel.

Source: Purdue

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up