The exponential growth of ecommerce over the last few years means supply chain logistics need innovative solutions to answer new challenges. To support more drastic peaks, expectations of faster delivery times and increasing SKUs (stock-keeping units), ecommerce fulfillment operations are now prioritizing flexibility and scalability. However, due to increasing labor shortages, resulting in added temporary labor, the traditional approach to scale is no longer enough. Manual operations are too expensive, low in efficiency and always subject to errors. With the recent pandemic adding the extra need for human distancing, a new approach is needed. AMRs can support supply chains by addressing these challenges, at scale.

What are AMRs?

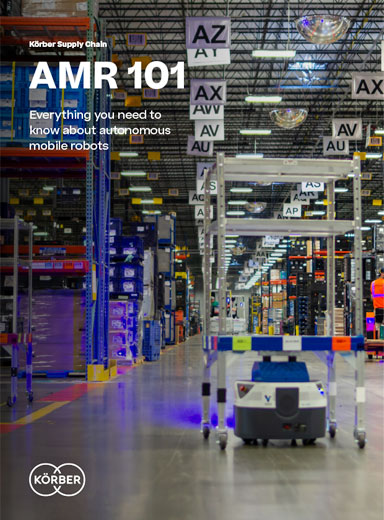

Autonomous mobile robots, or AMRs, are mobile devices that can autonomously navigate through a warehouse or fulfillment center. Their sensors, cameras and safety mechanisms allow them to build a digital map of their environment and move around the warehouse free of external guidance. They are a step up from AGVs (autonomous guided vehicles), which require some form of guidance to perform tasks, and which mostly follow a fixed path. Instead, AMRs adapt in real time to the surrounding space, safely detecting and avoiding anything in their way. Without the need to follow a fixed path, they can get to more locations, quicker.

What can AMRs do?

AMRs improve logistics and operations efficiency by supporting floor operations, transportation and processing.

Download this paper to learn more about AMRs.

Sponsored by Korber

Fill out the information below to download the resource.

Article topics

Email Sign Up