Editors’ Picks

Found in Robotics News & Content, with a score of 8.85

…Albertsons Companies. Founded by ex-Tesla and Rivian robotics and manufacturing leaders, the company aims to automate the most common industrial task: moving and storing material. Clean slate approach dramatically simplifies warehouse operations Recent advances in actuation, controls, AI and rapid prototyping have enabled robotics to automate much of the material workflow and fulfill the promise of software applied to the physical environment. Mytra has assembled a team of leaders to tackle this problem and reduce hardware complexity by orders of magnitude compared to the status quo, delivering a universal system to address the common but critical industry task of moving…

Found in Robotics News & Content, with a score of 12.56

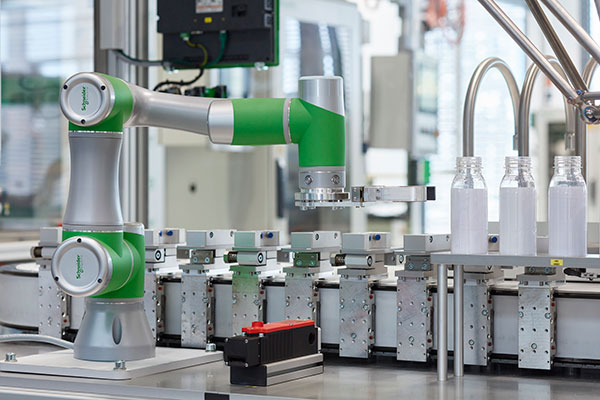

…and integrates into EcoStruxure Machine Expert software. “As US manufacturing increases, the demand for smart machines is growing and customers are requiring robots with digital twin capabilities that validate machine performance to help them quicky increase production consistently, efficiently, and sustainably,” said Christine Bush, Robotics Center of Excellence leader at Schneider Electric. “We are partnering with our customers to understand their challenges and pain points, then responding with complete, customized automation solutions - from power products and HMIs to PLCs and robotics - to simplify the process and meet their needs.” Compatibility with EcoStruxure Machine Expert Twin, a digital twin…

Found in Robotics News & Content, with a score of 12.27

…Accelerator, which is funded through support from the Massachusetts Technology Collaborative (MassTech). The inaugural cohort was announced at MassRobotics annual partner’s celebration. The three month accelerator program began on February 5, 2024. $5 million initiative to support R&D, commercialization The MassRobotics Accelerator is funded by a recently-announced $5 million state initiative managed by MassTech to boost the robotics sector in Massachusetts. The initiative includes a focus on expansion of research and development (R&D), testing, commercialization, and workforce development throughout Massachusetts. Through the equity-free accelerator program, each participating startup will be awarded a $100,000 non-dilutive grant from MassTech. “Through this funding…

Found in Robotics News & Content, with a score of 20.67

…defect detection solution to accelerate AI development for advanced manufacturing and warehouse robotics applications. iMerit's defect detection application enables AI development teams to build high-precision machine learning models for fully-automated production lines on the manufacturing floor. The solution can be fully customized to streamline defect detection on material surfaces in manufacturing environments, enabling companies to tailor it to their specific factory needs. The new purpose-built application is fully integrated with iMerit's Ango Hub, an end-to-end enterprise-grade technology platform that enables AI teams to quickly and efficiently build scalable data pipelines and provide the building blocks for custom solutions. “AI is…

Found in Robotics News & Content, with a score of 5.60

…visualization platform that accelerates value and delivery with modern technology, we’re pushing the boundaries of what’s achievable.” This year’s event has been expanded and “reimagined” to include more ways for attendees to delve into the latest technologies, such as tours, inspirational keynotes, and more learning and networking opportunities, noted Rockwell Automation. Attendees will be able to experience the newest industrial automation with 500,000-sq.-ft. Expo, with over 120 booths, virtual product lines, Discovery Theaters, and guided tours. The company provided previews of its software: Fiix Asset Risk Predictor: Users can predict and prevent asset failure before it happens with a tool…

Found in Robotics News & Content, with a score of 17.53

PBC Linear plans to demonstrate CNC integration for its Applied Cobotics Cobot Feeder at FABTECH 2023 in Chicago this week. The Roscoe, Ill.-based company said its application kit delivers and stages parts to be placed inot a machining process. “By increasing the amount of raw materials to a workcell, the Cobot Feeder’s 17-tray, high-density, part-storage solution enables a machining, welding, stamping, forming, or deburring center to operate for longer periods of time without human interaction, significantly increasing productivity by up to 300% or more,” asserted Beau Wileman, Applied Cobotics and 3D platform product manager at PBC Linear. “In many cases,…

Found in Robotics News & Content, with a score of 10.29

The Advanced Robotics for Manufacturing, or ARM Institute today announced that it will award a total of $3.26 million across eight new projects that identify challenges facing U.S. manufacturers and propose technology solutions. The institute said it has funded and managed more than 150 robotics, artificial intelligence, and workforce development projects to date. “Our selections in this latest project call address diverse areas of need in manufacturing – from identifying and road-mapping needed robotics developments to directly creating solutions for the problems that manufacturers are facing today,” stated Dr. Chuck Brandt, chief technology officer of the ARM Institute. “These projects…

Found in Robotics News & Content, with a score of 11.60

…shortages, reduce labor costs, and enhance workplace safety in manufacturing and logistics,” stated Lior Tal, CEO of Cyngn. The Menlo Park, Calif.-based company provides self-driving technology for industrial vehicles that it said can mitigate labor shortages, reduce safety incidents, and increase productivity to meet e-commerce demand. Cyngn works to ease materials handling “We conservatively estimate that the addressable market for self-driving industrial vehicles is over $200 billion today,” said Tal. “We are well-positioned to deliver the next generation of autonomous driving solutions to some of the most pressing problems in the industrial space. AI is transforming the way work gets…

Found in Robotics News & Content, with a score of 8.68

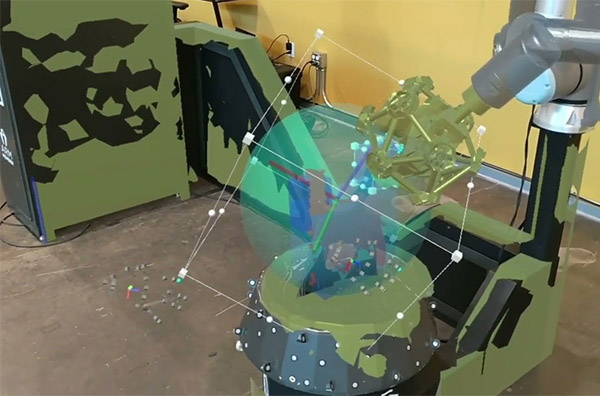

…Seattle-based company specializes in remote monitoring, control, and error-recovery technology for industrial robots. It said it plans to use the funding to support additional brands representing more than half of all industrial robots, expand partnerships with systems integrators in North America, and develop new software products. A record 517,385 new industrial robots were installed worldwide in 2021, according to the World Robotics Report 2022 from the International Federation of Robotics (IFR). That ongoing growth was driven by factors including labor shortages, reshoring initiatives, and rising e-commerce demand, said the IFR. A spinoff of the University of Washington, Olis Robotics claimed…

Found in Robotics News & Content, with a score of 14.45

…a practical, user-friendly way.” The company claimed that its technologies can help businesses operate more efficiently and continuously. PickGPT uses large language models (LLMs) to enable users to give instructions and feedback to robots through speech or text, according to Sereact. “By combining large language models and robotics, Sereact has created the world’s most accessible way of interacting with robots,” stated Ralf Gulde, co-founder and CEO of Sereact, in a release. “Today’s milestone will accelerate our mission of using fully autonomous robotics to overcome labor shortages, fix supply chains, and boost productivity.” PickGPT to democratize robot access Sereact asserted that…

Found in Robotics News & Content, with a score of 4.88

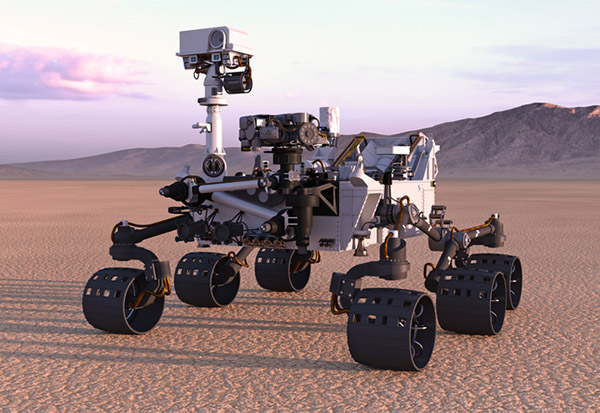

…for the Perseverance rover, it was less as $49. Technology has evolved much since the Apollo program, and conducting a crewed mission to the moon today could cost less than it did back then. Even so, manned missions cannot be conducted without essential supplies like oxygen, water, and food, which eventually add to the weight of the spacecraft and thus make the trip costlier. The biggest and the most apparent advantage of having a rover on board rather than a human is that no one’s life is on the line, and all the possible catastrophes en route are just visible…

Found in Robotics News & Content, with a score of 21.45

…Robots A/S has granted UR+ partner certification to its Applied Cobotics Cobot Feeder, an application kit that delivers and stages parts to be placed into a CNC machining process. “Machine tending is a critical process in manufacturing and one of the most popular applications for UR cobots,” said Joe Campbell, senior manager of applications development at collaborative robotics leader Universal Robots, in a press release. “By constantly feeding the cobot new parts to accurately pick and place, Applied Cobotics optimizes this process significantly,” he added. “We’re excited to include the Cobot Feeder in the UR+ product portfolio, benefitting our rapidly…