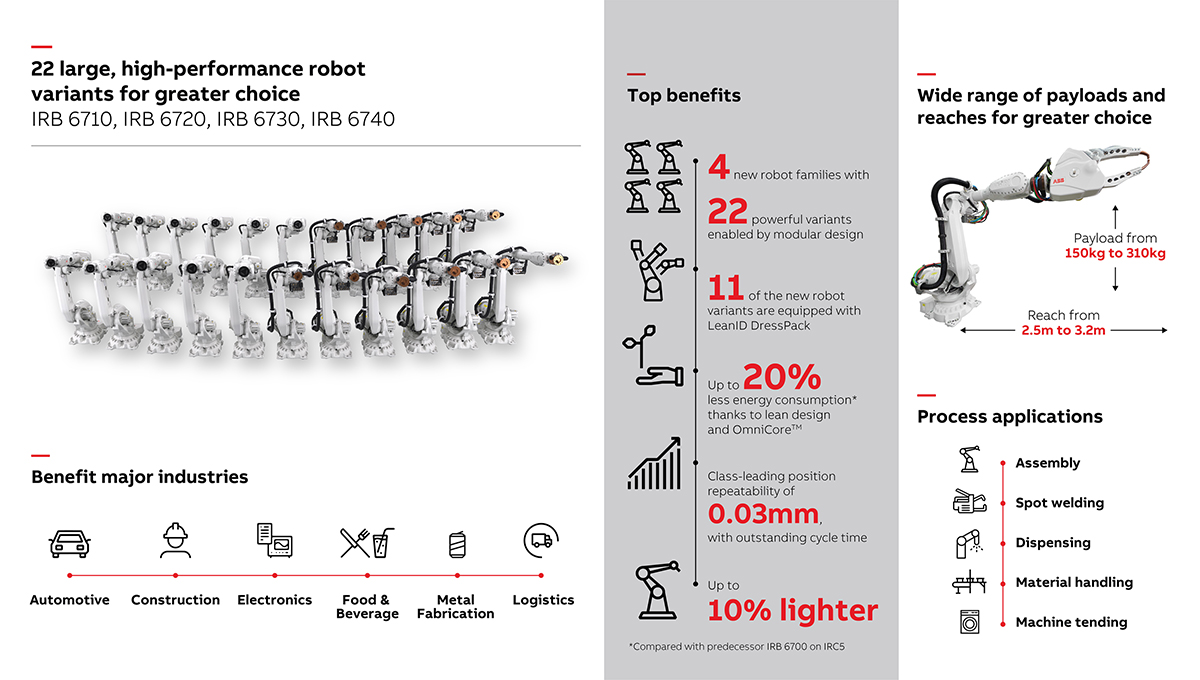

ABB Robotics this week announced that it is expanding its large robot range with four new models and 22 variants, offering more choice, improved energy efficiency, and greater performance. It also released new variants of its GoFa collaborative robots.

The next-generation large models include the IRB 6710, the IRB 6720, the IRB 6730, and the IRB 6740. They are suitable for payloads ranging from 150 to 310 kg (330.6 to 683.4 lb.), with a reach from 2.5 to 3.2 m (98.4 to 125.9 in.), said the company.

“Sustainable production is a major priority of automotive manufacturers, with 78% of companies identifying it as important to their business, and 77% identifying it as a priority for their customers,” stated Marc Segura, president of ABB’s Robotics Division, citing a 2023 company survey.

“ABB’s four new robots offer 22 variants and energy savings of up to 20%, responding to our customer’s needs, offering more choice and greater flexibility for more sustainable production,” he said. “These new robots will help our customers build resilience across a range of industries including automotive, general manufacturing, foundry, food and beverage, and logistics.”

OmniCore provides efficiency and accuracy

ABB said in a release that its OmniCore controller and a lighter robot design have led to 20% energy savings.

OmniCore also offers highly accurate motion control, noted the company. The systems include ABB's TrueMove and QuickMove technologies to achieve “class-repeating” repeatability with a minimum of 0.03 mm deviation, it claimed.

These capabilities make the new series of robots suitable for complex tasks such as spot welding, laser welding, screwdriving, and riveting, said ABB. This allows automotive manufacturers to achieve high-quality assembly, the Auburn Hills, Mich.-based company asserted.

“Our new robot range meets the needs of the rapidly growing electric vehicle (EV) industry,” said Joerg Reger, managing director of the automotive business line at ABB Robotics. “As manufacturers ramp up production of EVs and batteries, they can choose from a wide range of ABB robots to ensure they have the right variant to handle batteries of varying sizes, from individual cells and modules to complete packages.”

“They can also perform tasks such as high-precision car-body assembly and spot welding and enter restricted areas within a vehicle to install seats or dashboards,” he added.

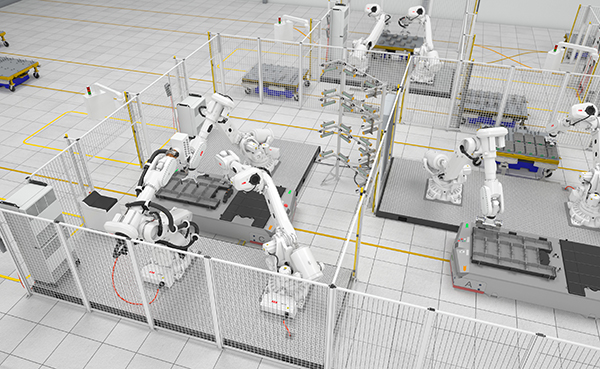

ABB’s new large robots are debuting at Booth 319 in Hall B5 at Automatica 2023. They will be working in a fully functional battery production cell at ABB’s stand, performing spot-welding tasks as well as loading and unloading EV-battery tray parts. One of ABB's autonomous mobile robots (AMRs) will feed the parts.

ABB also plans a digital launch of its expanded IRB line on LinkedIn on June 29 at 10:00 a.m. EDT.

ABB releases new GoFa cobots

ABB today launched the GoFa 10 and 12, two new variants of its collaborative robot. They can handle payloads of up to 10 and 12 kg (22 and 26.4 lb.), respectively, with a high degree of repeatability and a widened range of tasks, the company claimed.

The cobots are designed to work closely with humans and to be easier to program and integrate into production environments, lowering barriers to entry for new users, educators, and small and midsize enterprises (SMEs), said the company.

“Since our YuMi cobot hit the market in 2015, we have built up an unparalleled cobot portfolio meeting growing demand for safe and easy-to-use automation solutions to plug gaps in skilled labor,” said Segura. “Addressing the need for collaborative robots with higher payloads and longer reach, our GoFa 10 and 12 cobots extend the benefits of automation to new industrial applications, even for first-time users.”

The GoFa 10 and 12 also offer tool center point (TCP) speeds of up to 2 m/sec. (4.4 mph) with 0.02-mm repeatability—a two-fold improvement over comparable systems, said ABB. They are IP67-certified against moisture and dust ingress and enable cobots to be used for demanding tasks such as machine tending, welding, parts handling, polishing, and assembly, it added.

The GoFa 10’s 1.62-m (5.3 ft.) reach is 14% more than others in its class and enough to cover U.S. pallets, said ABB.

Robots built for ease of use

The GoFa 10 and GoFa 12 cobots are straightforward to program, deploy, and use. ABB's Wizard software is designed to facilitate setup. It allows even non-specialists to quickly automate their applications by manipulating simple graphical command blocks rather than writing complex programming code, according to the company.

Pre-installed on the cobots’ ABB’s FlexPendant robot controller, the ABB SafeMove monitoring app includes features for safe speed limits, standstill monitoring, and orientation supervision. This enables human-machine collaboration without requiring bulky protective barriers or fencing, it said.

The combination of the GoFa's intelligent torque and position sensors with the OmniCore controller ensures smooth movement for high-precision surface finishing, fastening, assembly, and testing tasks, said ABB. Features such as power re-generation and brake energy recovery reduce power requirements by up to 20%, enhancing sustainability, it asserted.

Users can tap ecosystem for innovation

Responding to the growing diversification of automation applications, ABB recently launched its ABB Robotics Ecosystem program. It brings together third-party accessories such as grippers, cameras, and customized software that are compatible with the ABB portfolio, including the new GoFa cobots.

The program lets users easily use innovation from across the fast-growing ABB Robotics ecosyste, said the company.

The GoFa 12 cobot will be making its tradeshow debut at ABB’s Automatica booth (No. 319) as part of two demonstrations of its use in high-precision machine tending and ultra-lean palletizing applications.

At Booth 502 in Hall 5, ABB partner Schunk will show its range of grippers and tools for a polishing application using the GoFa. ABB will have a digital launch for its cobots on LinkedIn on June 29 at 9:00 a.m. EDT.

Article topics

Email Sign Up