The Advanced Robotics for Manufacturing, or ARM Institute today announced that it will award a total of $3.26 million across eight new projects that identify challenges facing U.S. manufacturers and propose technology solutions. The institute said it has funded and managed more than 150 robotics, artificial intelligence, and workforce development projects to date.

“Our selections in this latest project call address diverse areas of need in manufacturing – from identifying and road-mapping needed robotics developments to directly creating solutions for the problems that manufacturers are facing today,” stated Dr. Chuck Brandt, chief technology officer of the ARM Institute. “These projects epitomize the strength of ARM Institute members and the impact of collaboration between different stakeholders in manufacturing.”

The ARM Institute is a Manufacturing Innovation Institute (MII) funded by the Office of the Secretary of Defense under Agreement Number W911NF-17-3-0004 and is part of the Manufacturing USA network. The consortium said it uses its ecosystem to make automation more accessible to U.S. manufacturers of all sizes, train and empower the workforce, and strengthen resilience and global competitiveness.

ARM has been based in Pittsburgh since 2017 and has a regional office in St. Petersburg, Fla.

23-01 project call topics

The ARM Institute explained that it creates its project calls with its internal team of experts, ARM members, and the U.S. Department of Defense. Its 23-01 Technology Project Call called for proposals to address the following topic areas:

- Automated robotic task planning

- Multi-robot, multi-human collaboration, task sharing, and task allocation

- Safe and scalable manufacturing of energetics

- AI in robotics for manufacturing

- Discovery workshops and market studies

The ARM Institute plans to award nearly $1.56 million in project funding from various sources, for a total contribution of approximately $3.26 million. It described each of the eight projects:

Technology Assessment of Virtual Commissioning for Day One Manufacturing Readiness

Project team: Wichita State University’s National Institute for Aviation Research (principal investigator), Siemens Corp., Spirit AeroSystems

Topic areas addressed: Discovery workshops and market studies

Description: Complex manufacturing systems can have many costs, errors, and hazards that may not be apparent in the design phase alone. Simulating systems by using digital/virtual twins allows for system testing in a digital environment prior to installation, enabling more successful installs and better “Day 1” experiences.

This project will create a report detailing the framework for the creation of a virtual twin for commissioning, and all the steps involved in its development. The framework package will contain the data and considerations needed to develop a full digital twin.

Autonomous Robotic Iterative Forging Phase 2

Project team: Ohio State University (principal investigator), CapSen Robotics, Yaskawa, and Warner Robbins Air Force Base

Topic areas addressed: AI in robotics for manufacturing

Description: This project builds on the outputs from the previously funded ARM Institute Autonomous Robotic Metal Forming project. There is a growing need for small-volume, high-mix manufacturing, such as in cases of manufacturing replacement components for aging systems or personalized medical implants.

However, there is a limited supply chain for one-off components, and complex components require expensive machining and/or tooling and dies. This project seeks to drastically accelerate the productivity of the robotic system created in Phase 1 of this project by:

- Reducing the time required to position the component on the lower die

- Removing the need for pauses during pressing to relieve forces and torques

- Allowing for larger amounts of deformation to be taken on each iteration

- Reducing the number of images needed for component geometry reconstruction

- Reducing the time to heat material to forging temperatures

- Reducing the amount of deformation needed to transform the initial geometry to the final geometry

- Reducing the frequency of component imaging

Robotic Manipulation of Granular and Paste-like Materials

Project team: Siemens (principal investigator), University of Southern California

Topic areas addressed: Safe and scalable manufacturing of energetics

Description: This project seeks to automate the manipulation of granular and paste-like materials with robotics to augment human operators for common handling tasks such as scooping and pouring precise amounts without spillage, including those used in the manufacturing of highly reactive materials. The outputs of this project can also be applied for use in the pharmaceutical and chemical industries.

The team will develop a robotic skill based on AI imitation and reinforcement learning to more safely scoop precise amounts of granular and paste-like materials. This will lead to greater versatility by enabling robots to operate in a flexible way in a broad class of manipulation applications, making them easily reconfigurable to adapt to a different process at lab scale and in production.

The project will also require little time to deploy and re-purpose by reducing programming, training, and calibration efforts through machine learning and AI.

The Path to Adopt Multi-Modal AI and Rapid Re-tasking & Robot Agility Project

Project team: Siemens (principal investigator), University of Southern California

Topic areas addressed: Discovery workshops and market studies

Description: This project will build assess the state of the art and propose technology roadmaps for the following topics:

- Multi-modal inputs for AI: Recent advancements of foundation model developed at a surprisingly rapid pace (such as ChatGPT). These models are designed for multi-modal inputs and will dominate the AI landscape over the next years. This report will analyze their potential in manufacturing.

- Rapid re-tasking and robot agility: The need for lot-size-one production and flexible manufacturing requires rethinking the current deployment approach to robotics, where robots are often deployed for one specific purpose.

Discovery Workshops/Market Analysis for Space and Hypersonics

Project team: ASTM International (principal investigator)

Topic areas addressed: Discovery workshops and market studies

Description: This project will center on two topics: terrestrial manufacturing for space and manufacturing of hypersonic components and structures. The ASTM Team will conduct a literature review, followed by an in-person workshop, and then follow up surveys to develop these two reports.

The team will also use the standards organization's network of nearly 30,000 subject-matter experts.

Time-Optimal Motion Planning using Convex Sets

Project team: Dexai Robotics (principal investigator), Massachusetts Institute of Technology (MIT)

Topic areas addressed: Automated robotic task planning

Description: Fixed manipulators perform tasks that require speed and correctness. As the restaurant industry struggles to return to pre-pandemic levels and continues to navigate workforce shortages, robotics can help to fill the gap.

This project will build upon Dexai Robotics’ existing product by doubling improvement on ingredient pickup robot moving time, improving the planning time for utensil pickup, and improving on meal throughput. While the use case is focused on the food industry, the deliverables from this project could benefit the broader robotics community by increasing speed and accuracy for almost any robotic manufacturing application.

Manipulating Fabric with Robots for Pick-and-Place Operations

Project team: Apparel Robotics Corp. (principal investigator), MassRobotics

Topic areas addressed: Automated robotic task planning and AI in robotics for manufacturing

Description: Clothing manufacturing is a very labor-intensive process, with 80% of the total labor cost attributed to material handling, and most labor manufacturing is completed offshore. For the garment manufacturing industry to progress meaningfully towards automation, several effective fabric-handling technologies must arise.

This project will develop new flexible robotic material handling capabilities required to unload a cutting table or a conveyor that has a number of cut nested fabric pieces of varying sizes and geometries on it. The project will:

- Use a vision system to identify the cut fabric piece based on the shape and other features

- Develop an adaptable end-of-arm-tooling (EOAT) to adjust to the geometry of the fabric piece to be picked up

- Leverage the fabric gripper technology developed by Apparel Robotics

Beyond garment manufacturing, the proposed system could bolster automation capabilities in aerospace and other industries working with flexible, fabric-like materials.

Collaborative Framework for Robotics Training

Project team: Aris Technology (principal investigator)

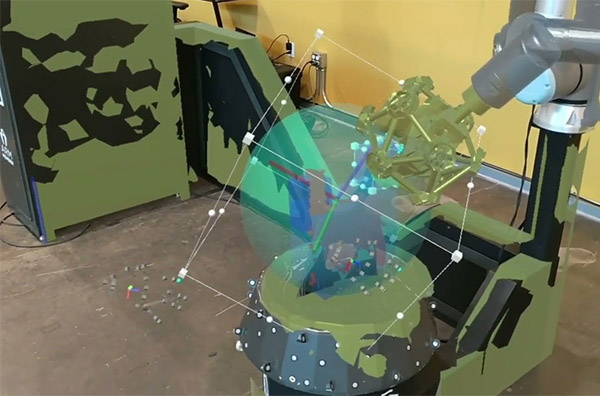

Topic areas addressed: Multi-robot, multi-human collaboration, task sharing, and task allocation

Description: Robotic adoption has been limited by a lack of flexible robotic systems and difficulties in upskilling a large industrial workforce. Enabling shop-floor operators with the tools to work with human-friendly robots will help to reduce this limitation.

The project will develop a collaborative framework to assist various organizations with assigning robotic tasks based on an individual operator’s unique subject-matter expertise. This framework will be designed for both human-robot and robot-machine collaboration to increase the adoptability of the robotic system with existing infrastructure.

ARM members focus on the future of U.S. manufacturing

The ARM Institute noted that funded projects are just one benefit of membership in the organization. It said it “catalyzes collaboration across our nearly 400 member organizations that span industry, government, and academia to lead the way to a future where people and robots work together to respond to our nation’s greatest challenges and to develop and produce the world’s most desired products.”

The institute invited attendees to its members-only National Annual Member Meeting, which will take place from Nov. 13 to 15 in Pittsburgh. The meeting brings members together for three days of in-person collaboration, networking, and knowledge-sharing.

Contact the ARM Institute at [email protected] to learn more about membership.

Article topics

Email Sign Up