3D printing can be a much more efficient production process than other types of manufacturing, but it also generates plenty of waste. Botched prints, leftover filament and other scraps can quickly add up.

The campus at the University of California, Berkeley, has embraced the technology, and there are more than 100 3D printers on campus. But 3D printing also generates around 600 pounds of trash annually. Much of that waste comes from discarded prototypes or failed prints generated by novice makers.

While Berkeley students do use a lot of bio-based PLA, which is theoretically compostable, most waste management companies don’t give the material enough time to decompose before being taken to a landfill.

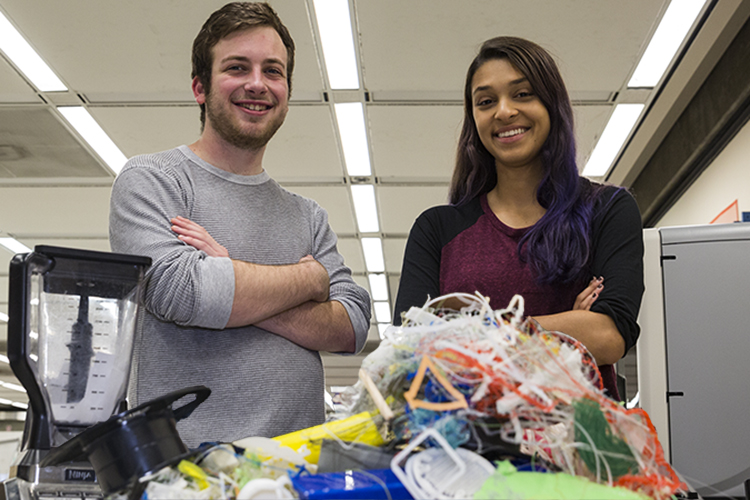

Mechanical engineering student Nicole Panditi and environmental sciences major Scott Silva have come up with a potential solution. Working through the Student Environmental Resource Center, Silva, Panditi, and Ph.D. student Michel Clemon have launched the 3D Printer Filament Reclamation Project. They are creating a system that grinds up and melts printer plastic to make new spools of filament that can then be re-used in campus printers.

Right now the group is using a decidedly low-tech method for grinding up the plastic to recycle – an electric blender. They launched a successful crowdsourcing campaign to raise funds for an industrial plastics grinder and other equipment.

Once fully implemented, the program would allow the campus to recycle all of its 3D plastic waste on campus.

“It’s my personal goal to reduce inefficiencies in 3D printing so that the tech industry can reach its full beneficial potential without being haunted by mountains of ugly waste,” Panditi said.

The students have been advised by Cal Zero Waste, the recycling operation at Berkeley. “The idea is that the plastics would never have to leave campus,” said Cal Zero’s manager Lin King. “We would provide Berkeley-produced recycled filament and any discarded items would be sent right back to us.”

Source: UC Berkeley

About the Author

Follow Robotics 24/7 on Linkedin

Article topics

Email Sign Up