Clean room robots may be safer than employees, but they come with some risks. Particulate shedding, static electricity, and inadequate precision can make it difficult for robots to operate safely in the clean rooms.

How do these risks affect aerospace, electronics, and pharmaceuticals manufacturing, and how can they be resolved?

Risks of clean room robots

Robots often seem like the perfect solution to the strict hygiene needs of clean room environments. There are advantages to using clean room robots rather than humans to manufacture sensitive items. However, robots have cleanliness risks to consider.

Particulate debris

Humans are often considered the biggest risk in a clean room environment — they shed an estimated 40,000 skin cells every hour and track in biological debris when they enter a clean room.

Robots don’t have these issues. They can stay in the clean room 24/7 and obviously don’t have biological risk factors.

However, robots can still shed debris that can threaten the integrity of a clean room. Most people wouldn’t notice, but machines drop particulate matter during regular operation.

For example, a rubber belt on a robot will shed bits of material over time as it wears down. Friction between metal or plastic components on a robot can also trigger particulate shedding during normal operations.

Electrostatic discharge

Electrostatic discharge (ESD) is one of the most common risks in electronics manufacturing specifically. Any time electronics like printed circuit board (PCBs) or semiconductors are being handled, ESD should be a concern.

Static can be caused by humans, such as the electricity generated by clothing rubbing together. However, robots are capable of presenting ESD risks, as well.

ESD can damage or even ruin electronic components during manufacturing. This poses serious quality control challenges due to the increased risk of product defects. ESD can even injure clean room robots.

If materials or electronic components in the clean room generate static electricity, the robots could experience a short circuit that causes a malfunction. This could lead to more severe damage, such as damage to parts, goods, or the robot.

Inadequate precision

Clean rooms are often required for sensitive products in the manufacturing process. For instance, the delicate ribbon cables in many small electronic devices can tear or break easily during assembly.

Similarly, chemicals and other components used in pharmaceuticals have to combine in highly specific amounts. Robots may be capable of performing these tasks, but they require careful programming and part selection.

For example, many advanced clean room robot systems have options for several different end effectors, including soft vacuum grippers. Soft robotic grippers improve the range of delicate parts clean room robots can handle, but careful programming is still necessary to ensure precision and accuracy.

How to prevent robot-related contamination

Despite the risks, adopting clean room robots has clear benefits for businesses. In fact, the increasing adoption of robotics is largely due to their increasing capabilities.

But what can businesses do to minimize the risks associated with clean room robots so they can perform their jobs safely? Robotics developers can use non-conductive materials like rubber or fiberglass for the exterior plating and grippers on clean room robots. This minimizes the likelihood of the robot spreading ESD.

Careful electrical grounding in the clean room can also reduce the risk of electrical accidents. Many clean room robots have a thick exterior casing to prevent ESD and contamination.

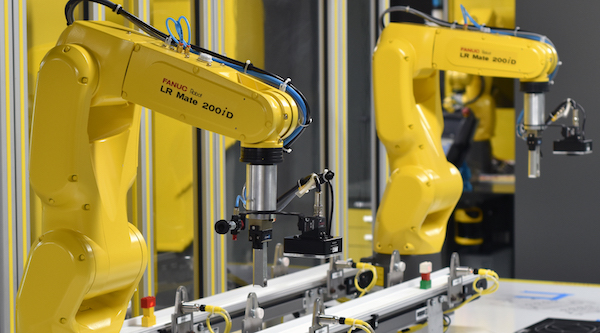

For example, the FANUC LR Mate 200iD/7C clean room robotic arm is completely encased in an outer shell. This shell is IP67 water resistant and dust proof, preventing both types of debris from getting either in or out. The shell material itself is non-conductive to prevent ESD risks.

Robots like the LR Mate are also a great example of how clean room robot designers navigate precision concerns. The LR Mate is a six-axis robot, so it has a wide range of motion and flexibility. It can also integrate with many types of end-of-arm tooling (EOAT), which is important for dexterity in clean room applications. These design qualities improve the robot’s ability to safely and delicately handle fragile materials.

Clean room robots can also be designed with an interior vacuum or high-grade seals to prevent particulate shedding. Staubli provides six-axis arms that are rated for clean room applications.

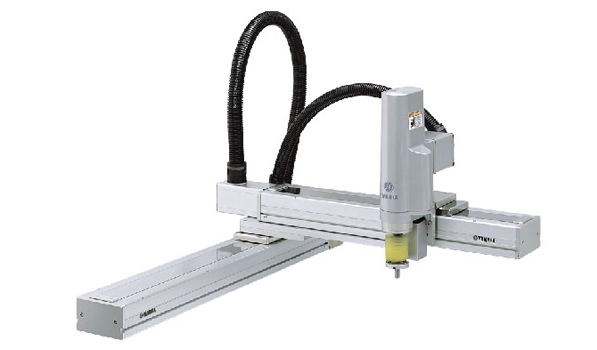

Yamaha’s clean room actuators have high-grade seals that serve a dual purpose — the seals prevent dust debris from leaking from the robot and improve suction for a performance boost.

How clean room robots can work safely

The global market for clean room robots could grow from an estimated $6.4 billion (U.S.) in 2022 to $25.6 billion by 2030 at a compound annual growth rate (CAGR) of 18.77%, according to Research and Markets. The analyst firm noted that it includes a variety of robot types, from collaborative and parallel to SCARA.

Clean room robots have a few key risks, but they are still generally safer than humans in highly sensitive manufacturing environments. Engineers must ensure that such robots are able to operate effectively in clean rooms by taking steps to prevent accidents and contamination.

Innovative robotic grippers, interior vacuums, and non-conductive materials can help clean room robots work safely and efficiently.

About the author

Emily Newton is a tech writer who enjoys writing about the latest innovations changing our world. Read more of her articles online at Revolutionized Magazine.

Article topics

Email Sign Up