All robotic arms need a quality cable management system if they're to avoid frequent downtime. Corrugated tubing is a popular choice, but there's a better option that will keep your cables running longer: triflex® R cable carriers from igus. Read on to find out how these two industry heavyweights match up head-to-head.

Round 1: Cable Installation

How can cables be installed?

Corrugated tubing

- Can only be installed via hose ends

- Cables with plugs that are too large can't be installed

triflex® R

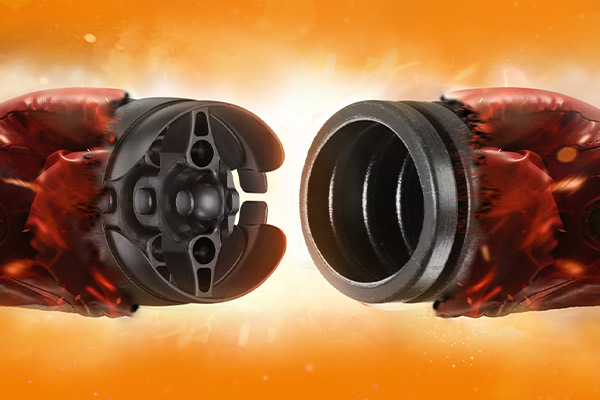

- Can be pressed in externally

- Can install any cables, regardless of the plug size

Round 2: Replacement after damage

How can damaged areas be replaced/repaired?

Corrugated tubing

- Damaged areas cannot be repaired or replaced

triflex® R

- Damaged links can be removed and replaced with ease

Round 3: Tensile strain

How do the two products behave under tensile strain?

Corrugated tubing

- Stretches significantly

- Load is transferred to cables

triflex® R

- Minimal stretching

- No additional load for the cables

Round 4: Length Adjustments

What options are there for adjusting length?

Corrugated tubing

- Can only be shortened with cutting tools

- Cannot be lengthened

triflex® R

- Individual links can be removed and added with or without tools

Round 5: Torsion

What happens when torsional forces occur?

Corrugated tubing

- Little-to-no torsion occurs

- Cables can twist and abrade, leading to breakages

triflex® R

- 7-12.5° torsion angle per link

- Up to 900° torsion angle per meter

- Cables are protected from torsional forces

Round 6: Defined minimum bending radius

Is there a limit to the amount of bending possible? Will damage occur if the product is bent too far?

Corrugated tubing

- No minimum bend radius

- Hose and cables can be damaged during excessive movement

triflex® R

- Minimum bend radius of 50mm - 182mm

- Built in torsion-stops to prevent chain from bending too tightly

If you're interested in triflex® R as a cable management solution for your robotic applications and want to learn more, contact an expert today, or visit our triflex® R webpage!

Article topics

Email Sign Up